Electro-Hydraulic Basics: Direct and Indirect Control (Part 1 of 2)

1. Introduction

In this blog, we introduced the electro-hydraulic system. Specifically, we explain the basic actuation of a single or double-acting cylinder by means of a solenoid actuated valves. The blog used two different circuit to actuate the cylinder. The method of actuation are direct and indirect control. In the previous blog on direct and indirect control, indirect control actuates the cylinder by means of an intermediate valve (or in electro-hydraulics, a solenoid) while direct control is an opposite to it. We used one scenario or problem to be the basis for the circuit to be simulated. The problems is described as

A double-acting hydraulic cylinder extends when an electrical push button is pressed. Upon release of the push button the cylinder is to retract. The double-acting cylinder must must be retracted or extended with 50% of the input air pressure.

The problem can be represented in two ways. One circuit employs the direct control where a push button directly activates the solenoid valve. The other circuit used a relay to activate the solenoid and this utilized indirect control. As mentioned earlier, the main difference between the two approach is the used of an intermediate component (a final control element) between the cylinder and the actuating button. Also, indirect control are commonly used for large cylinder and high speed operations. In this blog, we focused our solution to the problem by only utilizing a single solenoid valve. In the next section, the circuits is discussed in details.

2. Circuit and Simulation

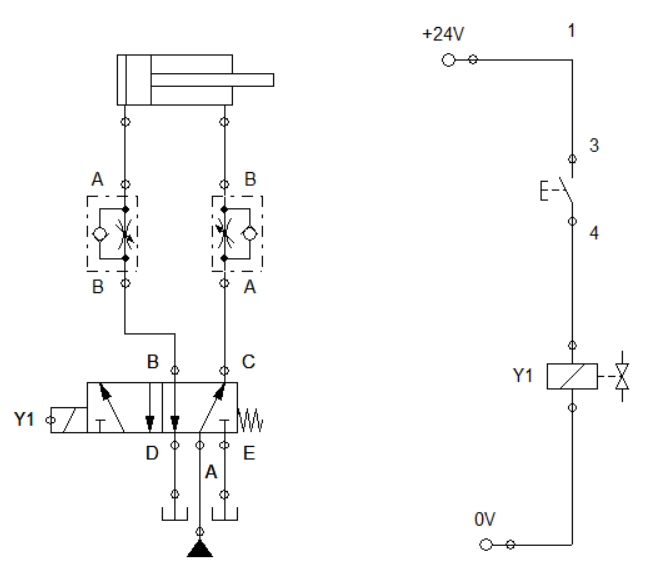

We start with direct control implementation of the problem. The hydraulic circuit for both method is the same. It consist of a double acting cylinder, a pair of one-way flow control, and a single solenoid actuated 5/2 way directional control valve with spring return. Similar to the previous blog on hydraulics, the one-way control valve limits the speed of the cylinder while the 5/2 way DCV drives the cylinder to extended or retracted position. The hydraulic circuit is shown in Figure 1.

Figure 1. Electro-hydraulic Circuit for Direct

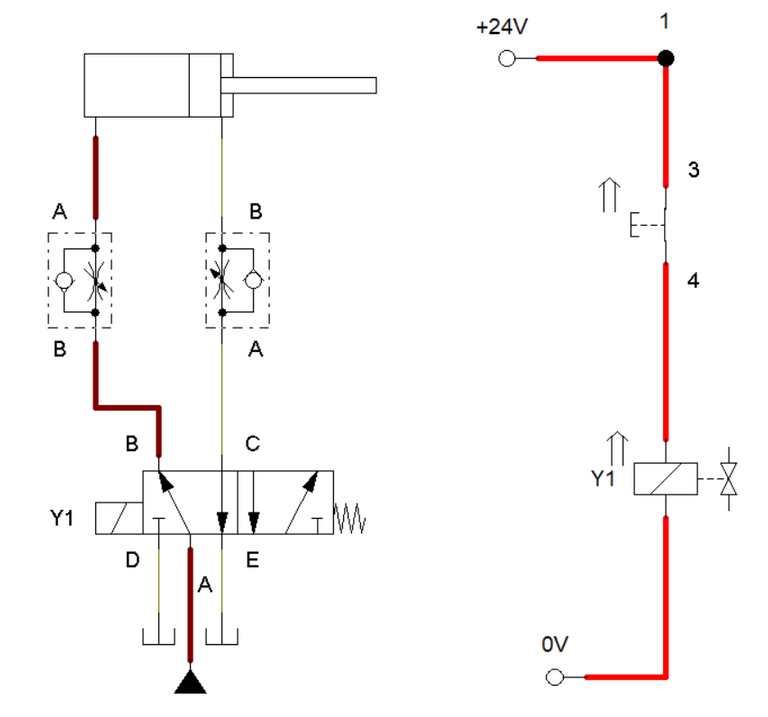

For the direct control, the electrical control circuit utilized a push button and a solenoid. The push button activates the solenoid when pressed while the solenoid activates the 5/2 way DCV. When the push button is pressed, electricity activates the solenoid which causes the 5/2 way DCV to shift the output from port C to port B. The shifting of output results to extending the cylinder. This is shown in Figure 2. The animated simulation is shown in Figure 3.

Figure 2: Push button is pressed (Direct Control)

Figure 3: Simulation of Direct Control

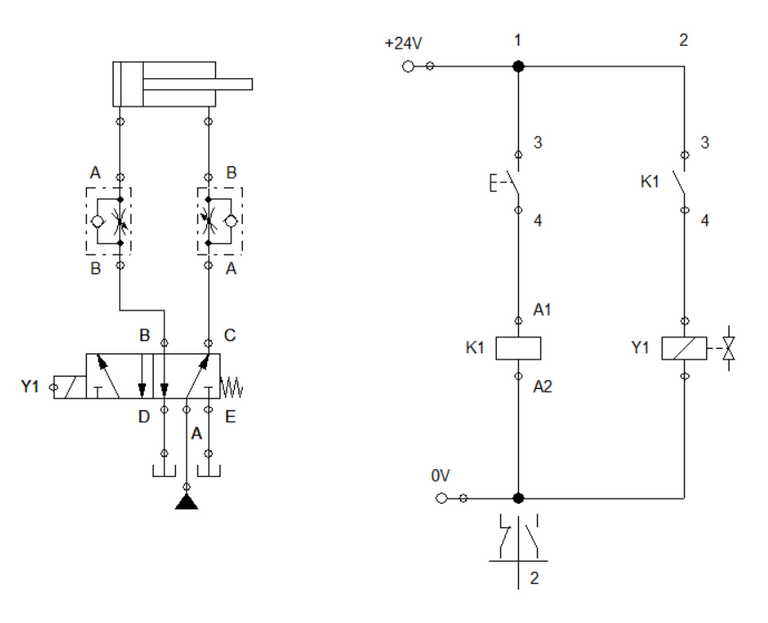

For the indirect control, we used a relay to activated the solenoid instead of putting it directly after the push button. The relay K1 is directly connected to the push button so that solenoid is controlled by the relay contact than the push button. When the push button is pressed, electricity energized the relay coil K1 which causes the latching contact K1 to switch from normally open to close. This result to electrical flow across the solenoid and activate it. The circuit configuration is shown in Figure 4. The simulation is shown in Figure 5.

Figure 4. Electro-hydraulic Circuit for Indirect Control

Figure 5. Simulation of Indirect Control

3. Conclusion

In this blog, we discussed on the two basic way to actuate the hydraulic cylinder. Direct control activates the solenoid directly from a push button while indirect control enables the solenoid by means of a relay. The difference between the two method of actuation is the use of a final control element in the indirect control. This enables indirect control to operate larger hydraulic cylinders or at high speed operation. On the other hand, direct control are the simplest wat to actuate a hydraulic cylinder.

4. References

[1] Hydraulic Basic Level. online access

[2] Hydraulic Advance Level. online access

[3] Electro-Hydraulic Basic Level. online access

[4] Electro-Hydraulic Advance Level. online access

(Note: All images and diagram in the text are drawn by the author (@juecoree) except those with separate citation.)

If your are interested in pneumatic and hydraulic series, you can read:

Pneumatic and Electro-pneumatic

1. Pneumatic Basics: Direct Control

2. Pneumatic Basics: Indirect Control

3. Pneumatic Basics: AND and OR Logic

4. Pneumatic Basics: Memory Circuit and Speed Control

5. Pneumatic Basics: Dependent control

6. Pneumatic Basics: Multiple Actuators

7. Electro-pneumatic Basic: AND and OR Logic

8. Electro-pneumatic Basics: Interlocking, Latching and XOR logic

9. Electro-pneumatic Basics: Distribution of Workpiece

10. Electro-pneumatic Basic: Ejecting a workpiece

11. Electro-pneumatic Basics: Basic Automation

12. Electro-pneumatic Basics: Automation with Counter

12. Electro-pneumatic Basics: Automating with Timer

13. Electro-pneumatic Basics: Cementing Press (Time Dependent Control)

14. Electro-pneumatic Basics: Embossing Device

15. Electro-pneumatic Basics: Bending Device

16. Electro-pneumatic Basics: Introduction to Logic Module

17. Electro-pneumatic Basics: Automating with Logic Controller

18. Electro-pneumatic Basics: Logic Controller for Multiple Actuators

19.Electro-pneumatic Basics: Time-dependent control with Logic Controller.

Hydraulics and Electro-Hydraulic

20. Hydraulic Basics: Direct Control

21. Hydraulic Basics: Indirect Control

22. Hydraulic Basics: Dual Pressure Value and the AND Logic

23. Hydraulic Basics: Shuttle Valve and the OR Logic

24. Hydraulic Basics: Sequencing Multiple Cylinders (Actuators)

25. Hydraulic Basics: Automating Multiple Cylinders (Actuators)

Posted with STEMGeeks