Electro-pneumatic Basics: Basic Automation ( Automatics Washing System)

1. Introduction

In the previous blogs, we explain the basic controls and actuations of pneumatic and electro-pneumatic system in reference to the problem or scenario at hand. We talked about logical operation, interlocking, latching and sensor placement. In this blog, we present and discus basic automation in the electro-pneumatic system. We create a circuit for an automatic washing system with its operation describe as:

A container of washers is to be dipped in and out of the cleaning bath. The start button initiate the washing. The dipping on the cleaning bath is continuous until stop button is pressed. Once stop button is pressed, the container returns to initial position. By switching off the main valve , the container should not fall into the bath with an impact.

The problem asked to automate the washing of the container by extending and retracting the piston of a double-acting cylinder. The process needs to sensor to acknowledge the position of the cylinder head at an instance. By placing the sensors and relay correctly, the continuous dipping can be achieved. The dipping can only be stop after pressing a push button. In the next section, the circuit and the simulation is discussed in details.

2. Circuit and Simulations

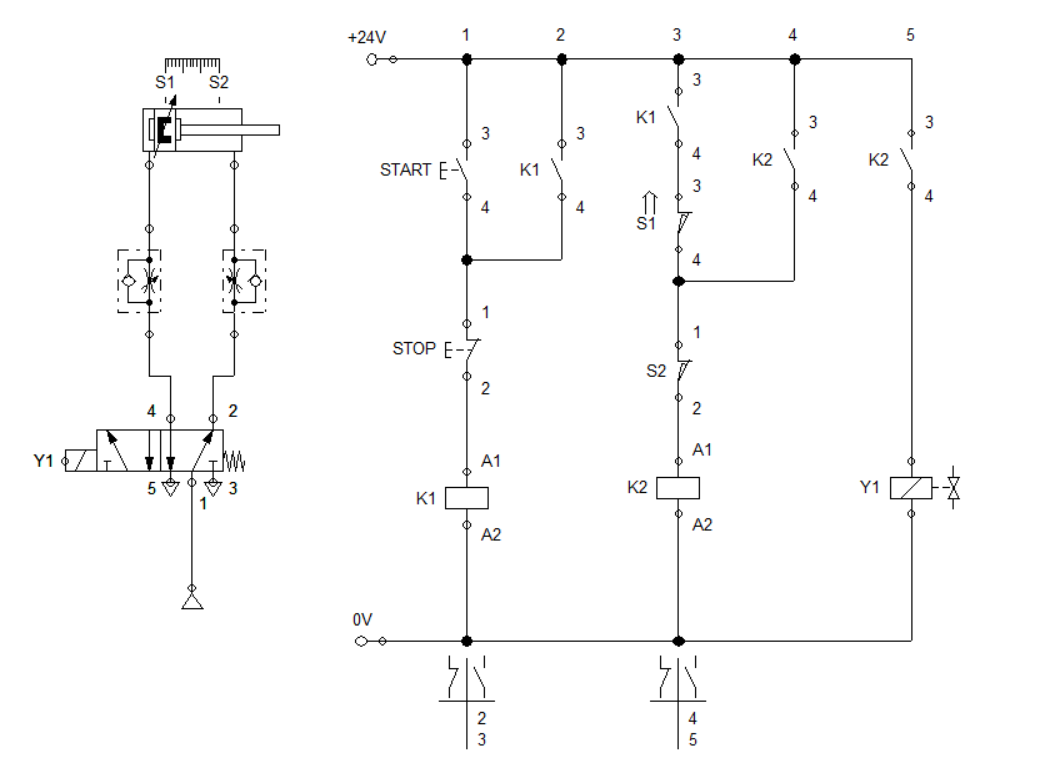

We set up the pneumatic cylinder by joining a double-acting cylinder, single solenoid 5/2 way directional valve and one-way flow control valve. The one way flow control valve minimized the speed of the extension and retraction of the cylinder while the single solenoid, 5/2 way directional valve actuated the cylinder in response to the electrical controller. The electrical control circuit consist of two push button, two relays and a solenoid. The connection is shown in Figure 1.

Figure 2: Start push button is pressed and relay coil K1 is energized.

When start push button is pressed, the current flows to the relay coil K1 and energized it. All K1 contacts shifted from normally close to open or in reverse. The closing of contacts K1 sustain the activation of relay K1 hence it is latch to the start push button. The latching allowed us to sustain the activation to automate the succeeding processes. After relay K1 is activated, closed contact K1 in ladder 3 activates relay K2 which eventually activate contacts K2, as shown in Figure 3.

Figure 3: Relay K2 is activated

After the K2 relay is energized, as shown in Figure3, all contact K2 switched from normally open to close or in reverse. At ladder 5, closing K2 energized the solenoid Y1. This caused the 5/2-way DCV to open port 4. Once port 4 is open, air pressure actuates the cylinder to extend.

Figure 4: Cylinder extend after solenoid Y1 activates.

When the piston has fully extended and reach the S2 position, the break switch S2 cuts off the current to deactivate relay coil K2. If the K2 is not energized, all contacts returns to initial state that cause the cylinder to retract. As the cylinder retracts, S2 closes. Once the cylinder reach full retraction, S1 is closed. Hence the K1 relay is sustained by the latch, the cylinder extends and repeats the process. The process continues as long as the stop button is not pressed.

Figure 5: Process repeats after cylinder retracts.

By pressing the stop push button, the continuous extending and retracting stops due to deactivating the latching to relay K1. The deactivation of the holding contact at K1 stops the energization of relay K1.

Figure 6: Full simulation of Automatic Washing System

3. Conclusion

We created a basic automation circuit, shown in Figure 1. Automating processes required controllers with full integrated sensors that acknowledge the position or condition at an instance. In this blog, we create a circuit for an automatic washing system that shows how to configure a basic automated process in electro-pneumatic.

4. References

[1] Pneumatic Basic Level. online access

[2] Pneumatic Advanced Level. online access

[3] Electro-pneumatic Basic Level. online access

(Note: All images and diagram in the text are drawn by the author (@juecoree) except those with separate citation.)

If your are Interested in pneumatic and electro-pneumatic system, you can read:

1. Pneumatic Basics: Direct Control

2. Pneumatic Basics: Indirect Control

3. Pneumatic Basics: AND and OR Logic

4. Pneumatic Basics: Memory Circuit and Speed Control

5. Pneumatic Basics: Dependent control

6. Pneumatic Basics: Multiple Actuators

7. Electro-pneumatic Basic: AND and OR Logic

8. Electro-pneumatic Basics: Interlocking, Latching and XOR logic

9. Electro-pneumatic Basics: Distribution of Workpiece

10. Electro-pneumatic Basic: Ejecting a workpiece

Posted with STEMGeeks