Pneumatic Basics: Direct Control

1. Introduction

A single acting cylinder is to clamp a component when a pushbutton is pressed. As long as the push button is activated the cylinder is to remain in the clamped position. If the push button is released, the clamp is to retract. The single-acting cylinder must be retracted or extended with 50% of the input air pressure.

A double-acting cylinder is to extend when a push button is operated. Upon release of the push button the cylinder is to retract. The double-acting cylinder must must be retracted or extended with 50% of the input air pressure.

2. Method

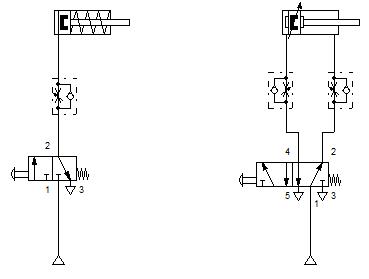

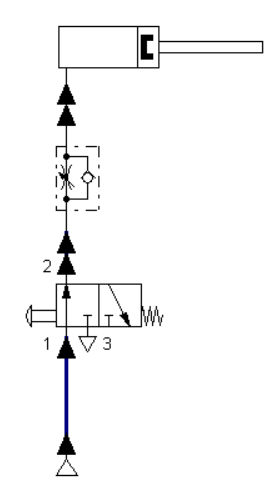

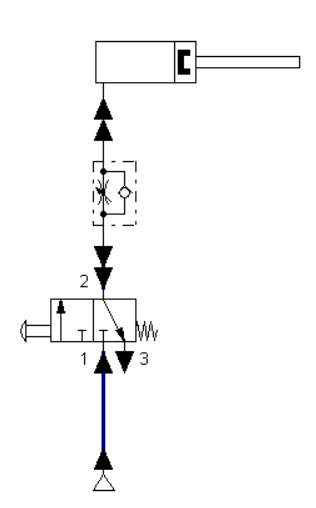

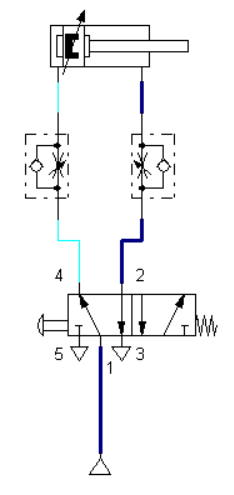

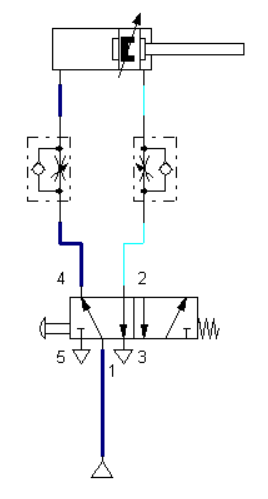

Direct control allows actuation of the cylinder directly to the actuation button and no intermediate control valve in between. In this simulation, the control valve used for the single acting cylinder is the 3/2 way valve. In this case, since the cylinder is of small capacity, the operation can be directly controlled by a push button 3/2 way directional control valve with spring return. When start button and 3/2 NC valve is operated, cylinder moves forward to clamp the work piece. When start button and 3/2 way valve is released cylinder comes back to the retracted position as shown in figure 1.

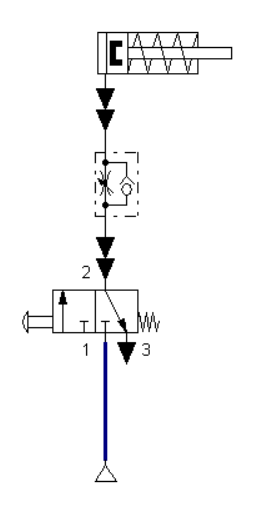

The initial position, the valve is unactuated, pressure is applied at the piston rod side and the piston rod of the cylinder is retracted. On operating the push button, the air passes through the valve from 1 to the 4 port and advances the piston rod. The displaced air flows to atmosphere via the ports 2 and 3. On release of the push button, the valve spring returns the control valve to its initial position and the cylinder retracts. Air returns from the cylinder via position and the cylinder retracts. Air returns from the cylinder via the exhaust port 5. The push button is released, the direction of movement is immediately reversed and the piston rod retracts. It is therefore possible to change the direction of movement without the piston rod reaching its initial or end position.

3. Conclusion

When the directional control valve is actuated by push button, the valve switches over to the open position, communicating working source to the cylinder volume. This results in the forward motion of the piston. When the push button is released, the reset spring of the valve restores the valve to the initial position [closed]. The cylinder space is connected to exhaust port there by piston retracts either due to spring or supply pressure applied from the other port.

4. Reference

[1] Pneumatic Basic Level. online access

[2] Pneumatic Advanced Level. online access

(Note: All images and diagram in the text are drawn by the author (@juecoree) except those with separate citation.)

Posted with STEMGeeks