New method for the manufacture of solid-state lithium-ion batteries

As we know, due to our need for energy, the development of batteries with higher energy density and longer life is a constant search for scientists dedicated to this area, in order to provide us with safe batteries, with higher performance and low cost, aspects that are very necessary for the massification of electric cars.

The future of electric cars depends on battery innovation. Edited image, original from pixabay.com.

Well, in this constant search for better batteries, lithium-ion and lithium metal batteries in solid state with inorganic electrolytes are the ones that offer greater safety for electric cars and other applications, but with current technology, the manufacture of this type of batteries has a very high cost, an excessive expenditure of electrolyte and other additives, in addition to a low volumetric energy density.

However, a new manufacturing method offers the possibility of implementing non-flammable ceramic electrolytes in solid-state batteries for vehicles, using the same process as conventional liquid-state battery production. This new technique was developed by scientists at Georgia Tech, and uses electrolytes that can infiltrate porous, densely packed, thermally stable electrodes. The method involves the separate fabrication of sintered solid-state ceramic electrolyte membranes and solid-state lithium-ion electrodes using a technology that offers reduced manufacturing costs and improved volumetric energy density in the solid cells. The proposed method was recently reported in the journal Nature Materials.

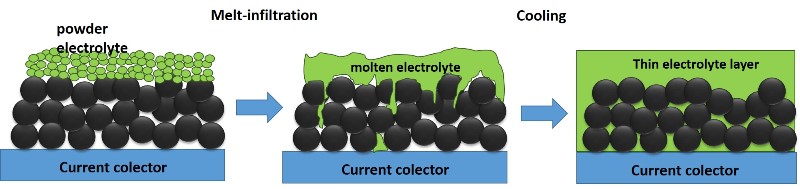

The new technique produces high-density composites by capillary, pressureless infiltration of a molten solid electrolyte. The method mimics the liquid electrolyte manufacturing process, the difference being that, while other manufacturing methods employ solid-state electrolytes that have melting points near or above 1000 °C, the new method uses a low-melting-point electrolyte, allowing the method to operate between 200 and 300 °C. And at these considerably lower temperatures, battery manufacturing is not only much safer but also much faster.

Illustration of the process of infiltration by fusion of the electrolyte on an electrode. Image elaborated by @emiliomoron.

With this new technique, 100% solid and non-flammable lithium-ion batteries could be manufactured using molten electrolytes that infiltrate the cell and then solidify during cooling, instead of conventional liquid electrolytes, but using the same conventional manufacturing process; so it could be implemented very quickly, manufacturing cells of any size and shape using the tools already developed for manufacturing lithium-ion batteries.

This fusion infiltration technology to produce 100% solid-state lithium-ion batteries is an important breakthrough, since the lifetime, performance and safety of lithium-ion batteries are highly dependent on the operating conditions, especially with regard to the operating temperature, because when conventional liquid electrolyte batteries overheat they tend to degrade and even catch fire, which requires the installation of expensive cooling equipment for their application. However, solid-state batteries, with ceramic materials, can tolerate high temperatures, so they do not need these cooling systems, which could reduce the manufacturing costs of electric cars.

The promising characteristics of this type of battery open up great opportunities for the accelerated adoption of safer, lighter and higher-performing solid-state batteries for electric vehicles. And while the technology is not yet available, if electric vehicles adopt solid-state batteries in the near future, this approach could be critical in enabling them to produce them in their current facilities and infrastructure, giving us safer and more economical electric transportation.

Any advance of this type is always welcome, practically the use and massification of electric transport is linked to the development of batteries, if these are more durable, economical and safe, electric vehicles acquire more autonomy and popularity, something essential for them to gain ground in the transportation market.

Thanks for coming by to read friends, I hope you liked the information. See you next time.

It is very interesting to see how technology helps us every day, and I suppose that with this ceramic, the cars are going to be made mostly of this material to reduce heat and also to make light vehicles.

As far as I know, ceramics is a very resistant material, I remember a propaganda in Venezuela for Carabobo ceramics where they hit a tile with a hammer and it did not break And now I understand what a very good possibility is to have a resistant and more ecological and efficient vehicle.

I congratulate you for making the graph so explanatory, your publications are always very educational and interesting, thank you for bringing us such good contributions.

Thanks friend @reinaldoverdu. Ceramic composites have many benefits and applications, especially due to their resistance and low heat conduction, so they are finding more and more applications, and in the case of vehicles we will surely continue to see other developments linked to ceramic products.

I have always thought that this will be the future, however, as you say, improvements are needed in the battery system. this will make a difference in the future that is yet to come. i also hope for this expansion in my country.

And when I talk about expansion I mean that also in Venezuela there is the possibility that there will be more electric cars.

@tipu curate 3

Upvoted 👌 (Mana: 0/78) Liquid rewards.

Greetings friend @lanzjoseg. I agree with you, electric cars will be the future, they are already gaining a lot of ground in the transport sector, but their massification depends on better batteries. I also hope to see that in Venezuela we advance in this direction, but the infrastructure needs to grow along with their introduction for them to be accepted by all. Thanks friend.