Failure Analysis with Fred Femto Field (Part 7)

Failure Analysis: The last but not the least FIB

Hey dear ions! Fred Femto Field here! Hope You're doing great!

Sorry for the late, but I have been doing some crazy research in the quantic world these last days!

So this will be my last post on the Failure Analysis Series, maybe later I will continue with this subject, but it's time for a pause...

And the final season goes to.... FIB (Focused Ion Beam)!!

The Focused Ion Beam (FIB) column is an optical instrument which focuses and scans an accelerated ion beam, typically Ga+ or Xe, on a sample in a vacuum chamber. It can be used in many fields of science for site-specific analysis, imaging, milling, deposition, micromachining, and manipulation. The main advantage of FIB for nanofabrication is its capability to perform direct patterning, preventing the necessity for complicated masks and pattern transfer processes. Therefore, the fabrication process is simpler, requiring fewer steps.

How does it work?

The utilized atoms are usually Galium or Xenon. In the case of Ga+, they are generated by a liquid meal ion source (LMIS), which is a small reservoir connected to a tungsten needle. Upon heating the reservoir, the ions flow to the tip of the needle, forming a small point source. A large negative voltage is applied between this needle and an extraction electrode. The balance between the electrostatic forces and the surface tension of gallium wetting needle results in the extraction of the Ga+ ions.

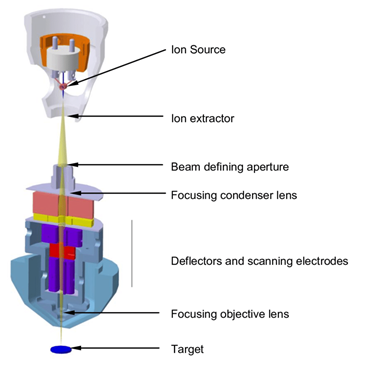

The simplest and most widely used ion beam column design consists in two magnetic lenses (namely a condenser and objective lens) to focus the ion beam on the sample. An optimum ion probe can be achieved by adjusting apertures, tuning all lenses, and doing final settings of the beam, such as stigmator and focus corrections. Cylindrical octopole lenses placed in an FIB system have multiple uses, which include beam deflection, alignment, and stigmation correction.

Figure's Source

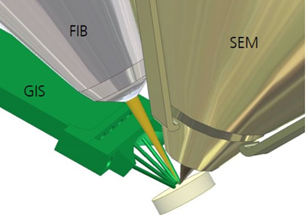

The beam profile of on the sample determines the imaging resolution and micromachining precision. Generally, the smaller the beam diameter, the better the achievable resolution and milling precision. FIB all alone, is only capable of removing material from the sample. However, when coupled with GIS (Gas Injection System), which locally delivers an organometallic gas, it can become an additive instrument, by depositing material. In term of deposition process, secondary electrons generated by the primary ion beam can crack hydrocarbon precursor gases, leading to local deposition of a conducting or insulating materials.

The FIB is nowadays usually combined with a scanning electron microscope (SEM) into a combined FIB-SEM workstation, allowing for easy site specific sputtering of material.

Figure's Source

FIB instruments are presently being used to develop the latest generation of micro electromechanical systems (MEMS) our next series...

Time to close the book on Failure Analysis for now! See You in a bit with exotic material!

Cheers from 10-15!!

References: