Failure Analysis with Fred Femto Field (Part 5)

Failure Analysis: SEM and EDS

Hi my dear electrons! Fred Femto Field here! Hope You're doing Great!

This time I want to talk about the Scanning Electron Microscope (SEM), which might be familiar for some of you, since it is a microscope being used for several applications other than Failure Analysis.

Let's start then!

What is it? How does it work?

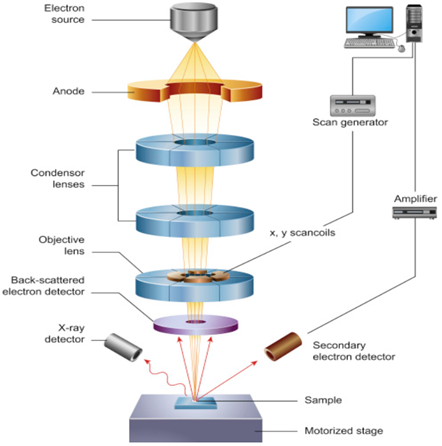

The SEM generates a beam of incident electrons in an electron column above the sample chamber. The electrons are produced by a thermal emission source, such as a heated tungsten filament, or by a field emission cathode. The energy of the incident electrons can be as low as 100 eV or as high as 30 keV depending on the evaluation objectives. The electrons are focused into a small beam by a series of electromagnetic lenses in the SEM column. Scanning coils near the end of the column direct and position the focused beam onto the sample surface. The electron beam is scanned in a raster pattern over the surface for imaging. The beam can also be focused at a single point or scanned along a line for x-ray analysis. As a result of the electron-sample interaction, a number of signals are produced. These signals are then detected by appropriate detectors.

When the electron beam hits the surface of the sample, it penetrates the sample to a depth of a few microns, depending on the accelerating voltage and the density of the sample. This interaction produces secondary electrons (SE) and backscattered electrons (BSE). Backscattered electrons belong to the primary electron beam and are reflected back after elastic interactions. On the other hand, secondary electrons are originated from the atoms of the sample. The SE are collected by one or more Everhart-Thornley detectors. It consists of a scintillator inside a Faraday cage, which is positively charged and attracts the SE. The scintillator is then used to accelerate the electrons and convert them into light before reaching a photomultiplier for amplification. The SE detector is placed at the side of the electron chamber, at an angle, in order to increase the efficiency of detecting secondary electrons.

Figure's Source

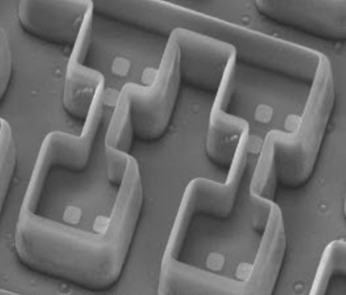

The intensity of the emitted electron signal is displayed as brightness on a display monitor and/or in a digital image file. By synchronizing the position in the image scan to that of the scan of the incident electron beam, the display represents the morphology of the sample surface area. While it cannot provide atomic resolution, some SEMs can achieve resolution below 1 nm.

Figure's Source

But What about the X-rays mentioned above? Are they neglected?

During the scan, there’s also generation of X-rays. In a SEM is a two-step process. In the first step, the electron beam hits the sample and transfers part of its energy to the atoms of the sample. This energy excites the electrons of the atoms to “jump” to an energy shell with higher energy or be knocked-off from the atom. If such a transition occurs, the electron leaves behind a hole. Holes have a positive charge which will attract negatively-charged electrons from higher-energy shells. When an electron from such a higher-energy shell fills the hole of the lower-energy shell, the energy difference of this transition can be released in the form of an X-ray. This energy is dependent on the atomic number, which is a unique property of every element.

Unlike BSE or SE, X-rays are electromagnetic radiation, and consist of photons. To detect them, the latest systems use silicon-drift detectors (SDDs). These detectors are placed under an angle, very close to the sample and have the ability to measure the energy of the incoming photons that belong to the X-rays.

Energy Dispersive X-Ray Spectroscopy (EDS) is then performed, using the spectral data captured by the detector. In this data each peak corresponds to the various elements that are present in the sample. The spectrum of X-ray energy versus counts is evaluated to determine the elemental composition of the sampled volume.

A lot of Information? Don't worry, next time it might be shorter, I will continue with TEM and then FIB!

See You, really, really, really soon!!!

Cheers from 10-15!!

References:

@heteronimo, thank you for supporting @steemitboard as a witness.

Click on the badge to view your Board of Honor.

Once again, thanks for your support!