Failure Analysis with Fred Femto Field (Part 2)

Failure Analysis: Something about DALS

Hi my dear photons! It's me, Fred Femto Field! How are you doing today?

Just got back from the Quantic world, and I was feeling in the mood for a small article about DALS (Dynamic Analysis by Laser Stimulation).

If you didn't follow the last post on Failure Analysis, you can always check it here.

So... DALS, is mainly used for Soft Defects, they are subtle defects that causes a device to be only partially functional and it might not operate under certain conditions. SDL (Soft Defect Localization) is a collection of various laser scanning isolation techniques, DALS (Dynamic Analysis by Laser Stimulation) is one among them.

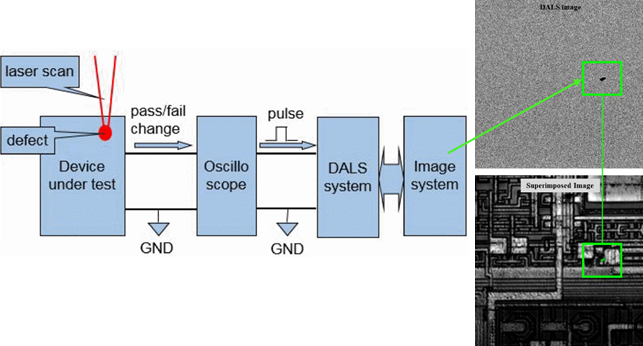

The DUT (Device Under Test) is stimulated using a 1.3 µm laser, that it is scanning the entire surface, pixel by pixel, while it is operating under normal conditions. During the scan, there is production of photoelectric and photothermal effects on the device, resulting to thermal energy production (heat), that creates electrical variation on the DUT.

Source: Ref. 1

If an oscilloscope is connected to the later, we can see that at a normal pixel no change is transferred to the oscilloscope. At an abnormal pixel, change is transferred to the oscilloscope and a pulse is captured by the DALS system.

The DALS system will lead the image system to mark a spot on the screen. By superimposing it on the DUT’s pattern, it is possible to see where the abnormal spot is located.

Source: Ref.2 (left) and Ref.3 (right)

Pretty cool right?!

So stay toned! I'll be continuing with the series pretty soon! I wish you all an amazing day!

Cheers from 10-15 !!

References:

1 - F. Beaudoin, K. Sanchez, P. Perdu, “Dynamic laser stimulation techniques for advanced failure analysis and design debug applications” Microelectronics Reliability, vol 47, pp. 1517-1522, November 2007.

2 - H. Chi, F. Diwei, S. Grace, “SDL analysis in temperature sensitive failure based on DALS system”, In Proc. IEEE International Symposium on the Physical and Failure Analysis of Integrated Circuits (IPFA), 2017.

3 -P. Hubert, C. Joyce, K. Kaye, “Soft Defect Localization of Hot Failure by Dynamic Analysis by Laser Stimulation using Hamamatsu iPhemos", In Proc. IEEE International Symposium on the Physical and Failure Analysis of Integrated Circuits (IPFA), 2018.

Congratulations @heteronimo! You have completed the following achievement on the Steem blockchain and have been rewarded with new badge(s) :

You can view your badges on your Steem Board and compare to others on the Steem Ranking

If you no longer want to receive notifications, reply to this comment with the word

STOPTo support your work, I also upvoted your post!

Vote for @Steemitboard as a witness to get one more award and increased upvotes!

This post has been voted on by the SteemSTEM curation team and voting trail. It is elligible for support from @curie and @minnowbooster.

If you appreciate the work we are doing, then consider supporting our witness @stem.witness. Additional witness support to the curie witness would be appreciated as well.

For additional information please join us on the SteemSTEM discord and to get to know the rest of the community!

Please consider using the steemstem.io app and/or including @steemstem in the list of beneficiaries of this post. This could yield a stronger support from SteemSTEM.

Hello,

Your post has been manually curated by a @stem.curate curator.

We are dedicated to supporting great content, like yours on the STEMGeeks tribe.

If you like what we are doing, please show your support as well by following our Steem Auto curation trail.

Please join us on discord.

Congratulations @heteronimo!

Your post was mentioned in the Steem Hit Parade for newcomers in the following category: