MANGO:-IT ORIGIN AND OTHER IMPORTANT THINGS TO NOTE ABOUT IT.

Mango is one fruit i love so much, it gives me joy eating it

Introduction

A mango is a stone fruit which belong to the Anacardiaceae family, which are flowering plants that produce fruits. Mangoes are native to south Asia (that means it is mostly found in south Asia) and it is the national fruit of India, Pakistan, and the Philippines. The leaves are considered to be toxic and can kill cattle or other grazing livestock, mango growers and livestock owners need to be mindful about not locating grazing areas near mango groves and not feed production discards to animals.

Mangoes are a popular, nutritional tropical fruit, which are now one of the most important fruits crops in tropical and subtropical areas of the world. They originated in India, were they have been cultivated for more than 4000 years.

source and source

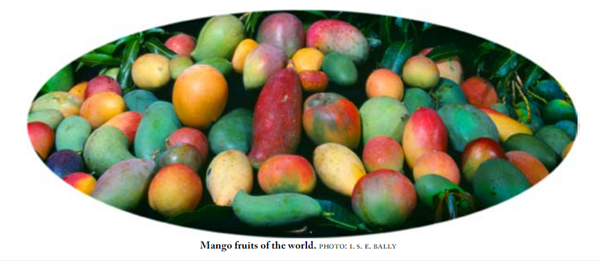

The botanical (Mangifera indica L.) is the most economically important fruit in the Anacardiaceae (Cashew or poison ivy family). Other important members of this family Includes cashew and pistachio. The mango is the most important foodstuff for inhabitants of the tropics after the banana. There are 150 cultivars of mangoes produced around the world. Producing areas can be grouped in 6 regions:-

- Florida (USA), Mexico, Central America

- West Indies (Caribbean Islands)

- South America

- Africa/Arabian Peninsula

- Indian Subcontinent

- Indochina (China)/Indonesia/Pacific

source

Classification of Mango

Kingdom: Plantae (Plants)

Subkingdom: Tracheobionta (Vascular plants)

Superdivision: Spermatophyta (Seed plants)

Division: Magnoliophyta (Flowering plants)

Class: Magnoliopsida (Dicotyledons)

Subclass: Rosidae

Order: Sapindales

Family: Anacardiaceae (Sumac family)

Genus: Mangifera L.

Species: Mangifera indica L.

source

Some problems associated with mango

The key features relevant to the profitability of mango production are the identification of mango market demand and its seasonality prices, seasonal fluctuations in availability, supply competitors, importer requirements, the option of added value processing, and sales promotions: the balance between these components will determine product price (Litz, 1997). To optimize mango production (harvesting, transferring, shipping, packaging and handling), we need to focus on production in relation to problems encountered throughout the chain as a whole. The practical problems relating to mango are conveniently classified into those which are largely pre-harvest in nature and those that are largely post-harvest.

Pre-harvest factors:

Production seasons are short (2 weeks to 2 months).

Varietal appearance and flavour are diverse.

Maturation time is variable.

Fruit abortion and premature fruit abscission results in yield decreases.

Irregular flowering leads to irregular fruiting.

There is year to year fluctuation in production

Post-harvest factors:

Overall the shelf-life is short.

Post-harvest, mangoes ripen rapidly.

Mango is sensitive to storage temperatures below 12oC.

Anthracnose (Colletotrichum gloeosporoides) is the most important post-harvest disease, causing huge losses and wastage of mangoes. source

Growing

Mangos can be grown in a wide range of soil types, from light sandy loams to red clay. Deep, rich, well-drained soils provide the best production and fruit quality. Some producers plant trees on sloping sites to prevent waterlogging the root system. Mangos grow best in ambient temperatures ranging between 70º to 75ºF. Commercial mangos are propagated vegetatively, meaning the trees are reproduced via asexual reproduction by grafting onto rootstock.

Harvesting

Mangos marketed in the United States are usually picked at the mature green stage to withstand postharvest handling practices. Mangos are picked by hand or by using a long picking pole which has a canvas or nylon bag attached near a cutting blade to catch the fruit. Ladders and hydraulic lifts are also used to help pickers reach fruit high in the tree canopy. Mango fruits are usually picked before they are fully ripe with the stem intact and after they develop red, orange, or yellow color. The long stem assures that the internal latex, or juice, does not leak. The fruit are stored stem end down on racks to further prevent latex from dripping on other fruit. The fruit bruises easily and must be handled carefully to avoid damage.

Packaging

Industry harvesting guidelines recommend that mangos be protected from exposure to direct sunlight while they wait transport to the packinghouse. Direct sunlight results in sunburn and higher flesh temperatures, which in turn accelerates ripening and shortens potential shelf life. On most farms, the fruit may wait from 30 minutes to 6 hours before they are transported to the packinghouse. Mangos can either be offloaded to the packinghouse in field crates or from trucks with large cargo holds. Upon arrival at the packinghouse, mangos are transferred into a water flume system, where they are sprayed and brushed to remove soil, latex and other organic materials. Next, the fruit is pre-sized and placed back into crates. Then, in order to control fruit flies, mangos are immersed in a hot water dump tank for a time period that can range from 65 to 110 minutes, depending on fruit variety, weight, and size. The hot water tank is filled with potable water at 115ºF. Some packinghouses will then conduct a post-water treatment cooling, known as hydro cooling, after the hot water treatment to rapidly decrease the flesh temperature and reduce injury to the fruit. Hydro cooler water temperatures are usually maintained between 70º to 72ºF and the mangos are exposed to the cool water for about 30 minutes. Industry guidelines provide time and temperature recommendations for hydro cooler use with mangos to prevent water uptake into the harvested fruit. The fruit is transferred back to a packing line and graded by weight and size in accordance with USDA standards and/or buyer requirements. Grading allows for removal of mangos that are misshaped, bruised, cut, or have signs of decay. Some fruit may undergo a coating of wax to improve natural fruit gloss and reduce water loss during holding and transport. Mangos are packed into ventilated, single-layer cartons with or without lids. The openings in the cartons are important to ensure uniform temperature and humidity during storage and shipping.

Holding

Prior to shipping, mangos are held in forced air-cooling rooms where the temperature is maintained at 54ºF. Mangos produced in other countries are often picked at the mature-green stage in order to withstand the postharvest handling steps required to export them from the production areas to the retail market. Upon arrival, this fruit can be treated with ethylene gas in holding chambers in much the same way bananas are held in ripening rooms to induce faster and more uniform ripening and provide ready to-eat mangos that consumers prefer. source

There is more to know about the Mango fruit, but let me stop here.

I am

glotokens.

thanks for engaging my blog