Weakness in durability when overheating and attenuation is affected by engine vibration

Hello My Steemit friends! I hope you all are doing well!

By learning, reading we can find out weaknesses in endurance when overheating and attenuation are affected by machine vibrations, so we can find out how to overcome them. A little discussion from me about the weakness in endurance when overheating and attenuation is affected by machine vibration.

The use of iron has been tested is a very tough material and there are no serious problems caused by iron during the car is used, because this material is a material that is resistant to heat and friction. Even if the engine overheats, generally the first engine loser is not the engine block, but other components inside the engine

Iron has a melting point at 1,370 degrees Celsius, is a good conductor of heat, does not release heat easily and does not expand easily. Lack of use of iron in a weight that is too heavy compared to aluminum and can rust, aluminum is more expensive than iron, aluminum is more expensive than conventional machines that still use iron.

Aluminum is a material that is known to be lightweight, better than iron to conduct heat and release heat faster. Therefore engine blocks made of aluminum have better thermal efficiency using more economical fuels. It is also much lighter and must be resistant to rust without having to use a layer or mixture that is resistant to rust.

The use of lighter and stronger engineering materials to produce various kinds of engine components also has an impact, this needs to provide an opportunity for technicians to increase the power to weight ratio of the machine.

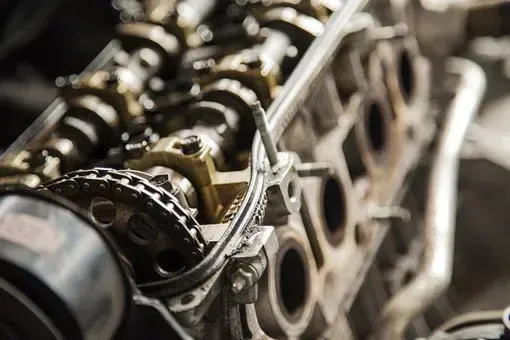

Likewise with the car components commonly found on the engine which include pistons, camshafts, timing chains, rocker arms, and various other types. When all components have opened all parts of the engine can be seen cylinder block.

Cylinder blocks or commonly called engine blocks are the strongest components in an engine that contains hundreds of engine parts found in modern engines. Because of its relatively large size, engine blocks make up 25% of the total weight of the engine so there is a lot of traction in reducing the block's weight.

Previously engine blocks were made from a mixture of cast iron because of their durability and lower costs, but due to the complexity of the engine design and the weight of the vehicle's engine growing, the consequence was that manufacturers wanted to use a light but a strong iron mixture.

One of the materials used is aluminum alloy, in 1930 aluminum alloy material was rarely used which due to durability issues, then in 1990 the use of aluminum alloy used in engine blocks surged because it could improve fuel efficiency and engine performance, both of these materials used exclusively for manufacturing machine blocks.

Aluminum engine blocks also require system improvements, in addition to radiators, some engines also cool engine oil so that engine blocks are more durable. Some machines without radiators such as bicycle engines, generally they have an automatic shutdown engine that can turn off the engine if it uses a heat engine as well to replace aluminum.

Well, aluminum machines are indeed more difficult to design, they are also more expensive compared to machines made from ordinary steel. Its benefits besides thermal are better, lighter compared to iron machine blocks. For example, the same engine block can be lighter by half compared to an iron engine block.

Easy Ways to Overcome the Vibrating Car Engine

The vibrating car engine makes the car jam or compiles the maximum speed of the car, which will be felt up to the cabin. This vibration moves to car parts such as dashboards or even to other components.

See the condition of the installation of the car engine is still working well or not.

How to start the car and see the rubber and bolt mounting the engine, if it doesn't shake and remains stable then the installation of the engine is still fine.

If the rubber and engine mounting bolts that support the engine to the chassis vibrate when the engine position is turned on, you must immediately replace the old engine installation with the new one.

Damage Analysis

Engine cylinder block which is the main component in a cylinder block vehicle is a house for pistons, the cylinder block made of cast iron or aluminum so that the strong cylinder block in the engine is one of the components that must be achieved also by students who can be material testing on the cylinder block is an improvement

Cylinder Block Construction

- Rigid loading pressures cannot change the elasticity in their shape

- Cylindrical block construction must have even cooling

- Light and strong

- Easily overhauled or replaced

Noisy Engine Sounds.

Possible Causes and Corrective Steps:

- Incorrect valve adjustment. Open the valve cover and exhaust valve then adjust the valve properly.

- Camshafts and rocker arm wear. Repair the rocker arm and camshaft or replace it with a new one.

- The machine chain tensioner system is broken/worn. Replace the engine chain tensioner with a new one.

- Sprocket tooth wear. Change sprocket teeth with new ones.

- Replace the camshaft holder and rocker arm wear.

Conclusion

Treatment and measurement processes that are in accordance with the theory will be able to produce quality repair services that are of good quality. But After Examination and Measurement, Most people find it difficult to understand the theories that are given to the supervisor.

Source

Manufacturing_Processes_and_Engineering_Materials

This post has been voted on by the SteemSTEM curation team and voting trail. It is elligible for support from @curie and @minnowbooster.

If you appreciate the work we are doing, then consider supporting our witness @stem.witness. Additional witness support to the curie witness would be appreciated as well.

For additional information please join us on the SteemSTEM discord and to get to know the rest of the community!

Thanks for having used the steemstem.io app. This granted you a stronger support from SteemSTEM. Note that including @steemstem in the list of beneficiaries of this post could have yielded an even more important support.