The Science Of Cast Iron | Part 1: What Is It?

If you've watched my recent video, First Time Restoring Cast Iron... Mistakes Were Made!, you'll know that my latest project around the (wannabe) homestead is cleaning up a pile of cast iron cookware that we found at a garage sale. As you may have gathered from the title, I didn't exactly get things right on my first attempt, which has prompted me to dig a little deeper and learn more about cast iron so I can do a better job next time around. So, the first thing I wanted to learn about the stuff is, "What in the world is it?" What makes cast iron different from regular iron, steel, or wrought iron?

Original Image Created Using Canva

My initial assumption was that cast iron must be a fairly pure form of iron that was just melted down and poured into a mold. After all, it is fairly primitive technology. Archaeologists have found that cast iron was in use in China as early as the 6th century BC. But, while it has been used through the centuries to make everything from tiny trinkets to bridges crossing entire rivers, my interest lies in its use as cookware.

So, What Is Cast Iron?

While cast iron does derive its name from the fact that it is cast into a mold while molten and then allowed to cool, I was interested to learn that it is not pure iron. In fact, cast iron has a higher carbon content than steel! The carbon content of steel can range from 0.3 % to 1.5% carbon by weight. Cast iron has a carbon content of 2.1% or higher!Cast iron generally starts out as pig iron, which is the stuff you get when you smelt iron ore in a blast furnace. Pig iron usually consists of about 93% iron, about 4% carbon, and trace amounts of impurities such as silicon, manganese, phosphorus, and sulfur.. To make cast iron, the pig iron is remelted along with scrap iron to lower the carbon content to around 3%. Then, the molten metal can be poured into a mold and allowed to cool.

The Four Types Of Cast Iron

There are four different types of cast iron: gray cast iron, white cast iron, malleable cast iron, and ductile cast iron.

Image Credit: Hb tuw|ShareAlike 4.0 International (CC BY-SA 4.0)

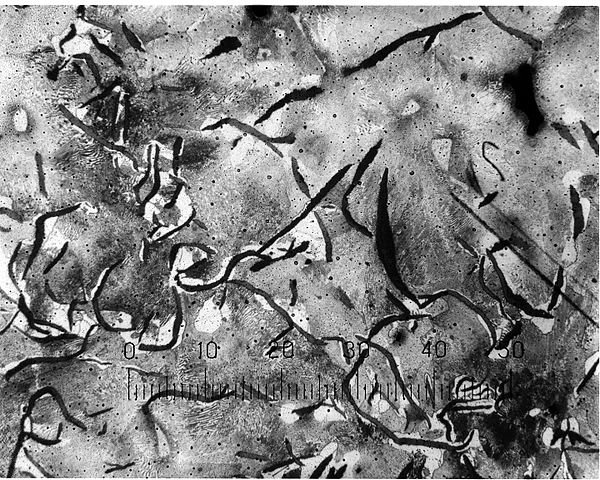

Gray Cast Iron

Gray cast iron, commonly called gray iron, is the oldest and most commonly produced type of cast iron. It derives its name from the gray interior color of the material you see when it cracks. The gray color is caused by the presence of graphite flakes that are embedded in the metal, which forms due to a combination of the composition of the alloy and the cooling process. Gray cast iron generally contains a higher percentage of silicon than white cast iron, and it is allowed to cool more slowly. The silicon in the alloy encourages the carbon to diffuse out of the metal and form graphite flakes that embed within the iron, a process known as graphitization. Additionally, allowing the cast iron to cool slowly gives the carbon more time to form into graphite rather than the iron carbide that is more prevalent in white cast iron.The graphite that gives gray cast iron its color also imbues it with several other physical characteristics. Gray iron is softer than its white counterpart, making it fairly easy to be machined or welded. It also has a compression strength comparable to steel, it is good at dampening shock, and it can hold up well to fairly extreme temperature fluctuations. These traits make gray cast iron ideal for many industrial and domestic applications including vehicle parts (gears, suspension components, and engine cylinders), wind turbine housings, bases for heavy machinery, and even cast iron cookware.

Image Credit: Perlit86 / CC BY (https://creativecommons.org/licenses/by/4.0)

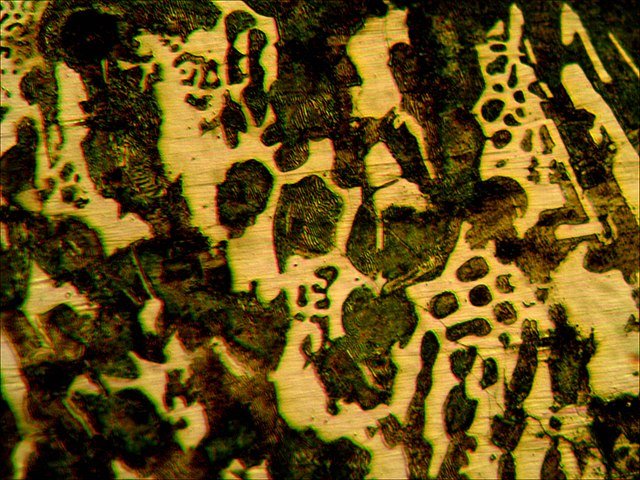

White Cast Iron

White cast iron, or white iron also gets its name from the appearance of the interior color of the metal. It takes on more of a white hue due to the iron carbide (also known as cementite) in the alloy mixture. White iron is made from an alloy with a lower percentage (ranging from 0.1 - 0.5% of silicon, and it is cooled more quickly than gray iron. This keeps the carbon from being able to fall out as graphite. Instead, it remains in the form of iron carbide.Iron carbide is a hard but brittle compound that is often times classified as a ceramic. Therefor, cast irons that contain high amounts of this cementite are generally hard and brittle, but they are very abrasion-resistant. This makes them useful for making shell liners and various parts in high wear-and-tear machinery such as ball mills, grinding mills, and pulverisors.

Image Credit: Überraschungsbilder|ShareAlike 3.0 Unported (CC BY-SA 3.0)

Malleable Cast Iron

Malleable cast iron starts out as white cast iron that is heated for up to 2 days and then annealed, or allowed to cool slowly. This gives some of the carbon in the iron carbide enough time to diffuse out and form graphite, much like it does in gray cast iorn; only the graphite in malleable cast iron forms nodules instead of flakes. The arrangement of these graphite nodules makes malleable cast iron less brittle than white iron, shock resistant, with a high tensile strength while retaining the wear resistance of white iron. These properties make it fairly comparable to a mild steel.Malleable cast iron is able to be worked into different shapes, making it useful for many different industrial applications from hand tools and electrical fittings to farm equipment and mining machinery.

Image Credit: Michelshock / Public domain

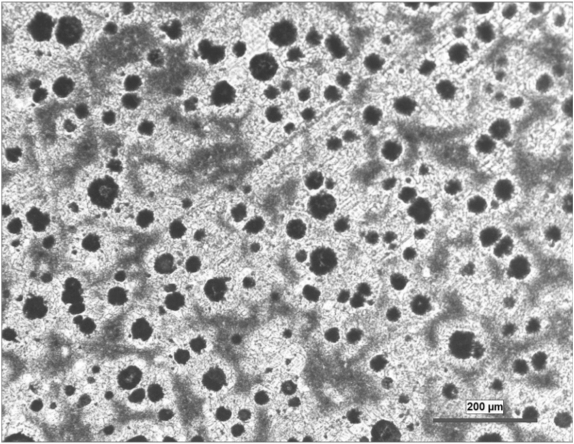

Ductile Cast Iron

Like malleable cast iron, ductile iron also has nodular-shaped graphite inclusions embedded in the metal. However, they are not formed by heat treating white iron. Instead, the nodules in ductile iron are caused by the addition of trace amounts of magnesium or cerium to the alloy. The way the graphite nodules arrange themselves make the material resistant to forming linear cracks, allowing ductile iron a greater degree of flexibility and ductility than other cast irons while still retaining comparable or even better wear resistance and strength than gray iron. It is also cheaper and much easier to cast than white iron or malleable cast iron.Malleable cast iron has found wide use as the go-to material for the manufacturing of metal sewage pipes. It is also used in the automotive industry for parts that are critical to the safety of the vehicle's occupants, including brake calipers and steering knuckles. In fact, the properties of ductile cast iron are so reliable that it is often used to make nuclear waste storage containers!

In Conclusion

Before doing a bit of research, I had no idea that cast iron was such an integral part of day-to-day life. The only things that I knew of that were made of cast iron were the old fashioned skillets that I would see at flea markets and garage sales. I thought that cast iron was an outdated technology really didn't serve any real modern purpose. Boy, was I wrong! I had no idea that there were so many different kinds of cast iron with such different characteristics to fit so many different applications. With such a variety of uses and low production costs, it's no wonder that cast iron has found a permanent home in industry worldwide.But, as I mentioned before, my main interest in cast iron lies in its use in cookware. In my next installment of The Science Of Cast Iron, I'll explore how cast iron skillets are made and why they remain so popular.

Congratulations @sustainablyyours! You have completed the following achievement on the Steem blockchain and have been rewarded with new badge(s) :

You can view your badges on your Steem Board and compare to others on the Steem Ranking

If you no longer want to receive notifications, reply to this comment with the word

STOPTo support your work, I also upvoted your post!

Do not miss the last post from @steemitboard:

Vote for @Steemitboard as a witness to get one more award and increased upvotes!

Congratulations, your post has been selected to be included in my weekly Sustainability Curation Digest for the Minnow Support Project.

That's awesome! Thank you!