Let's talk about printing in 3 dimensions

I once engaged a friend in a technology-related discussion where we discussed how far technology has come with time, especially with the advent of the internet and the massive amount of doors it opens to mankind. With the internet, we both agreed that the potential is unlimited. We were deep-rooted in our discussion when that friend of mine jokingly retorted that he cannot really take the internet seriously if it does not get to a point where he can just download his favorite food from the internet. Anyone listening to him on that day will probably think he's going nuts, including myself. That was about a few years back, how close are we to getting to what everyone would have believed was a crazy idea? Maybe quite close.

Everyday people dream of bringing their imaginations to life but piecing it altogether would take so much time and energy. This has been the end to so many possible inventions but as usual, technology is here to supply a helping hand and many are grateful for it. This magic solution comes in the form of 3-D printers.

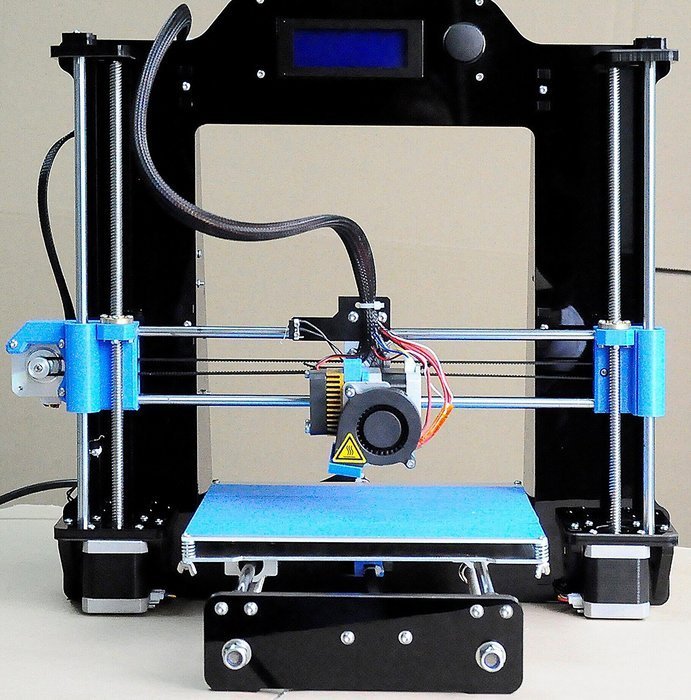

Now you might be wondering. What makes 3-D printing so special. Simply put, it can create a 3 dimensional solid from the content of a digital file. The process is also known as additive manufacturing. It involves building up by continuously adding successive layers of the material until the object has been created. This is what a 3-D printer does so now let's take a look at how it does it.

How 3-D printers work

A conventional three printer works just like an inkjet but it is fully controlled by a computer system. The printer builds up the 3-D object one step at a time. In the process, it repeatedly layers over the same area. The method by which it achieves this is called FDM (Fused Depositional Modelling).

The printer’s actions are completely automated and it produces an accurate model by transforming a three-dimensional CAD drawing into various 2-D(two dimensional) cross-sectional layers. That is, it produces 2-D layers that are compiled but unlike an inkjet printer there is no paper separation and molten plastic and other materials such as poly actin filament (PLA) are used. The layers are usually joined together with an adhesive and in some cases, ultraviolet light is used instead. 3-D printing is a genius technology but does it have any relevant uses? Here are some instances to prove that it does.

Uses of three 3-D printers

3-D printers were created for prototyping as it made it much easier for inventors and designers to show off their creations. Predictably this awesome piece of technology has now gone much farther than that and spread to many more places around the globe. It is now used across several fields. Here are four of its highly useful and relevant applications:

Education: An increasing number of institutions are taking advantage of 3-D printing to aid learning and improve learning methods. 3-D printers are now available for use in many institutions and some platforms even offer courses in 3-D printing. With 3-D printing, students are now able to easily produce real-life models of their work. Students get to interact with these models and see possible problems. They also get to understand concepts much better.

Medicine: with the recent emergence of a global pandemic advances in medicine are needed now more than they have been in a while. 3-D printing has gone a long way in making this happen. The concept has been implemented to enable different things that have helped health workers provide better care. Some like bioprinting which involves using the combination of biological materials such as cells and growth factors for the creation of tissue-like structures which are useful in manufacturing prosthetics. 3-D bioprinting is also used in creating metallic orthopedic implants, artificial organs, and even pills that are safe for consumption.

Construction: 3-D printing is not a new concept in construction. Specialized 3-D printers have been used for construction work as far back as the 1990s. It has a wide range of applications in these fields. Ranging from the creation of architectural models to printing of concrete and affordable housing with large-scale 3-D printers and even entire structures like the pedestrian bridge built in Alcobendas, Madrid, Spain in 2016.

Jewelry making: 3-D printing does not leave out the creatives. They can also harness its power in creating mind-blowing jewelry. Gone are the days where objects could not be printed out with metals. With 3-D printing, jewelry makers can create jewelry that would be impossible to make with the use of traditional methods. Pieces can now be customized at a much lower cost. Jewelry is usually printed with poly actin filaments, platinum, or gold.

Transport: it might be quite shocking but yes 3-D printing is being used in transport. The very first 3-D printed unmanned aircraft has been flown by professors from the University of Southampton. A company that deals with automobiles, KOR Ecologic also debuted a vehicle named Urbee which was created with a 3-D printed body.

How 3-D printers were invented

The entire concept of three-dimensional printing seems like new-age technology but it has been around for decades. It first came to light in 1981 when a man name Hideo Kodama published a paper detailing a rapid prototyping method that made use of photopolymers.

Though the concept had been introduced it was not until three years later that its use began. Charles Hull invented stereolithography which enabled designers to produce 3-D models of their works with the use of digital data. After his genius creation was released the concept continued to advance and by 1992 the first Stereolithographic apparatus equipment was developed.

Though the tech was advancing consistently the resulting products still had noticeable defects in most cases. There was also the issue of the machines being too expensive for the major target market, inventors, to purchase. All of this changed in the 2000s when the manufacturing processes underwent democratization. It helped capture people’s imagination and by 2006 a commercially viable product was released.

3-D printing now and in the future

Unsurprisingly, 3-D printing has continued to advance and evolve and there is no denying that it has had a massively positive impact on the world. It has broken into lots of relevant fields including medicine, aviation, art, education, and even aviation. It is now much more affordable than it used to be so an increasing number of people are getting to access it day by day. Incredible innovations are being presented regularly and hopefully, 3-D printing can be well integrated with other fantastic technology such as machine learning and robotics. This way its power can be fully harnessed and it can impact even more people.

Hmm. 3D printing in jewelry. Never thought of that. It would be interesting to see 3D jewelry in action. Could disrupt the market with low cost 3D printed jewelry.

I do hope that 3D printing gains in popularity and usage with housing. Affordable low-costs housing would be helpful for a lot of places. Especially in the Toronto and surrounding area where I am at in Canada.

I am pretty confident we will a massive boost in 3d printing applications in the coming years. The potential seems limitless. I will really love to witness a 3d printing being applied in the construction of actual structures in real life, beyond what I read in papers.

Thanks for your contribution to the STEMsocial community. Feel free to join us on discord to get to know the rest of us!

Please consider supporting our funding proposal, approving our witness (@stem.witness) or delegating to the @stemsocial account (for some ROI).

Please consider using the STEMsocial app app and including @stemsocial as a beneficiary to get a stronger support.