Precious Plastic - Technologies for the Future #1

Hello everyone !

For the past few years, I've been interested in the solutions that people are trying to bring to reconcile technologies and sustainable development, or even trying to counteract global warming.

While I believe that new technologies cannot provide a solution to every problem we face, I am certain that we can improve our quality of life and our ecological footprint by using them wisely.

So while vehicles made entirely from organic materials* are still science fiction, in this series of articles I'd like to introduce you to some solutions that fit my vision of a technological future.

I do not claim to have a global view of the problem, the stakes, or the solutions, but I seek through these articles to open up the discussion and exchange with you on the different topics we are going to discuss.

For this first article, I'd like to tell you about Precious Plastic, which is the project that inspired me to write these articles.

Precious Plastic

Precious Plastic is a project led by Dutch industrial designer Dave Hakkens (who was also behind the Phonebloks project) since 2013, it aims to democratize plastic recycling at a small scale. For this, they created a platform where they share the plans of their machines as well as tips on how to best recycle all kinds of plastics. Everything is open-source, you can build your own machines, make the modifications you want. You can even contribute to the evolution of the project by publishing your modifications, by bringing your plastic waste to workshops near you, or simply by participating in the discussion.

Screenshot of the Precious Plastic website ( CC-BY Precious Plastic )

Screenshot of the Precious Plastic website ( CC-BY Precious Plastic )

The problem :

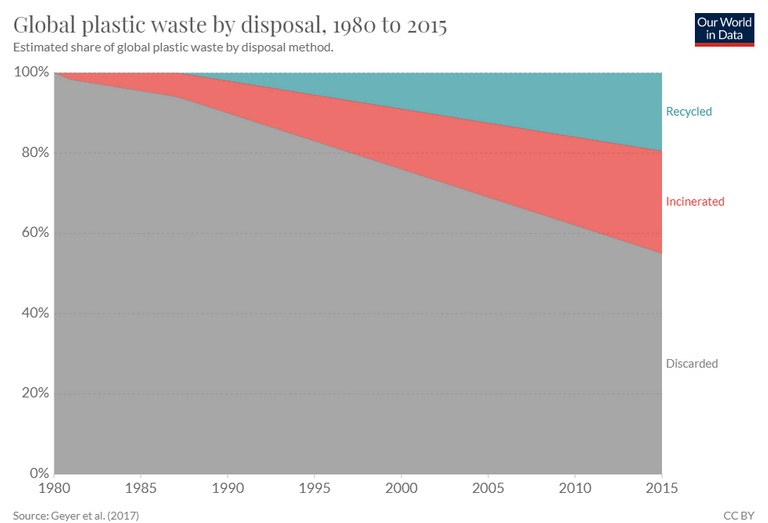

The ambition of this project is to participate in the recycling effort of plastic all over the world. Currently, less than 20% of the plastic generated worldwide is recycled [2] :

Figure created by OurWorldInData.org, with data from Geyer et al.[2], License CC-BY

Figure created by OurWorldInData.org, with data from Geyer et al.[2], License CC-BY

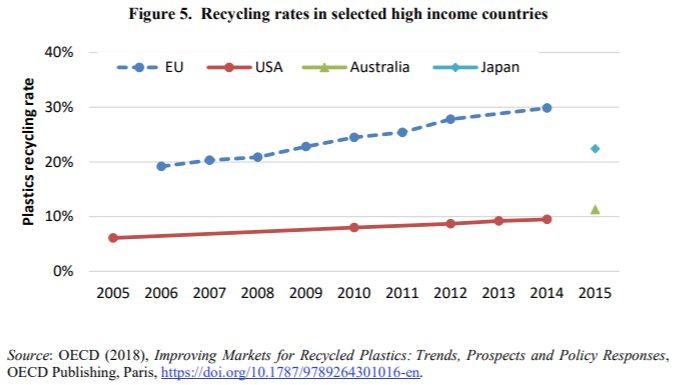

But not all territories have the same recycling policies, for example, the European Union recycles 30% of its plastic in 2014 against 11% for Australia and 9% for the United States :

Figure from the OECD report [1] © OECD 2018

Figure from the OECD report [1] © OECD 2018

And it is even more difficult for developing countries where there are not always structures in place capable of handling this waste. In Africa, only 4% of used plastics are recycled [4].

From this observation, Precious Plastic has set 2 development axes, education to practices more respectful of the environment and the creation of value from plastic waste. The latter is rather important for developing countries because the machines we will see in the following article have been designed to be easy to manufacture, as cheap as possible, with parts that are easily found, fixable and interchangeable (if you don't have access to the exact part you can always modify the plans). So we see people able to live from recycling plastic by creating new objects.

The machines :

The first machines were designed for small local productions and cover all stages from the initial waste to the finished product.

Shredder - CC-BY Precious Plastic

Shredder - CC-BY Precious Plastic

First, you need to use a shredder to reduce the plastic into small pieces. This step is necessary because the plastic coming out of this machine is easier to melt afterward. In addition, it allows to store it more easily since it takes less volume and offers the possibility of making mixtures of different colors. You can put in the shredder anything that contains only one type of plastic, from bottles to some toys and packaging, but also failed or out-of-use 3D printed parts!

Extruder - CC-BY Precious Plastic

Extruder - CC-BY Precious Plastic

Then you have the choice between the other 3 machines depending on what you want to do. The first one is the extruder, it turns plastic into a beam that you can wrap around a mold, turn into 3D printer filament (if the diameter is constant enough) or use it to make new raw materials.

Injector - CC-BY Precious Plastic

Injector - CC-BY Precious Plastic

Or you can use the injector. This machine also takes the plastic coming out of the shredder as raw material. With the help of a lever, the plastic is pushed into a tube that will gradually melt the plastic (you can see the 4 heating elements in brass along the tube). When the plastic has reached the right temperature, you will press the lever to push the melted plastic into the mold attached to the bottom of the tube.

The plastic fills the mold and solidifies into the desired shape. We let it cool down and then we open the mold to recover the manufactured parts. This is a fast and efficient method but the result depends greatly on the quality of your mold which can be expensive to produce.

Compressor - CC-BY Precious Plastic

Compressor - CC-BY Precious Plastic

Finally, you can choose the compression machine which performs the same function as the injector but allows you to make larger parts. The compression is obtained with a car jack.

With time, they wanted to allow a greater production capacity by developing a more professional range but always with the same open-source objective. You can see the different machines for professional use proposed here which are the basics of the basic range as well as a new machine to transform plastic into a 1m sheet.

Other One Army projects:

But Precious Plastic doesn't want to stop there. Their latest project, Beyond Plastic, aims to get rid of plastic completely in the manufacturing of everyday objects.

And through the creation of One Army, they embark on 2 other projects, Kamp and Story Hopper. Kamp aims to develop an example of an autonomous camp in Portugal, disconnected from the electrical grid and able to be self-sufficient in energy and food. As for Story Hopper, it is the realization of videos documenting different aspects of their views on ecology, recycling and lifestyles.

Finally, just last week, they released the Fixing Fashion project which brings together a set of tutorials to repair your clothes yourself (from understanding the difference between fibres to learning to sew and care for your clothes) and creates a community to encourage the repair, maintenance and enhancement of our clothes. You can find more information about this project on their website.

Conclusion

I'm not saying that one day everyone will have a small recycling line in their garage. But as we will discuss in the next articles, I think that a space gathering among other things these machines could allow to raise awareness about environmental issues by welcoming the public. People around could bring their plastic waste, they will know that it will be transformed into something useful and will give a boost to the local community depending on the number of products transformed or allow entrepreneurs to live from plastic recycling. In a way, I see it as the decentralization of recycling.

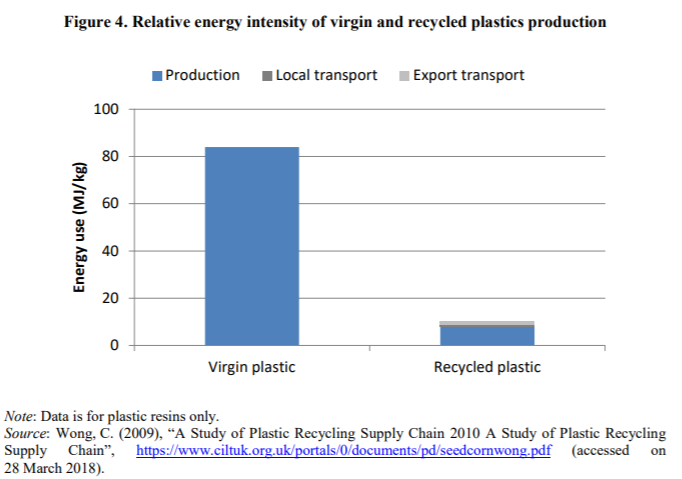

Currently, plastic recycling uses much less energy than the production of new plastic, so certainly Precious Plastic machines should not achieve the efficiencies of specialized recycling plants, but I would be curious to see where they fall on this graph:

Figure from the OECD report [1] © OECD 2018

Figure from the OECD report [1] © OECD 2018

And you, what do you think of this project?

Before leaving, here is a small example of a product made by Precious Plastic : (feel free to have a look at the other items on sale here)

Recycled plastic and metal chair - CC-BY Precious Plastic

Recycled plastic and metal chair - CC-BY Precious Plastic

Sources:

- [1]OECD Report on improving plastics management: https://www.oecd.org/environment/waste/policy-highlights-improving-plastics-management.pdf

- [2] Production, use, and fate of all plastics ever made BY ROLAND GEYER, JENNA R. JAMBECK, KARA LAVENDER LAW| Fig. 3 Cumulative plastic waste generation and disposal (in million metric tons) (Source used in the OECD Report[1])

- [3] https://ourworldindata.org/plastic-pollution

- [4] Africa Waste Management Outlook 2018 | The UN Environment Programme

- One Army website: https://www.onearmy.earth

- Precious Plastic website: http://preciousplastic.com

*It's a dream I've had for a long time, to be able to "program" an organism like a bacteria or a fungus so that its growth is done in a controlled form that would allow it to be used to make more or less complex objects (we're already starting to see things like bricks made from fungi).

Congratulations @robotics101! You have completed the following achievement on the Hive blockchain and have been rewarded with new badge(s) :

Your next target is to reach 7000 upvotes.

You can view your badges on your board and compare yourself to others in the Ranking

If you no longer want to receive notifications, reply to this comment with the word

STOPSupport the HiveBuzz project. Vote for our proposal!