Theobroma cacao L. husk as an antimicrobial agent in agricultural systems. A sustainable alternative

Author: @madridbg, through Power Point 2010, using public domain images.

Welcome back dear readers of the #hive community, this time I want to socialize with you a work that we have been doing from the Chemical Analysis laboratories of the Universidad Nacional Experimental Sur del Lago, which in the company of the colleague and Food Engineer Beatriz Urdaneta, we have addressed the potential and uses that can be given to the Theobroma Cacao L. Hull Theobroma Cacao L. .

As has been constant in my publications, this type of content will be socialized through the @stemsocial community who have remained at the forefront of scientific topics.

INTRODUCTION

Theobroma Cacao L, as an item was introduced in America by the Spaniards in colonial times, it was considered by the natives as "delicacy of the gods" for its distinctive aroma and flavor.

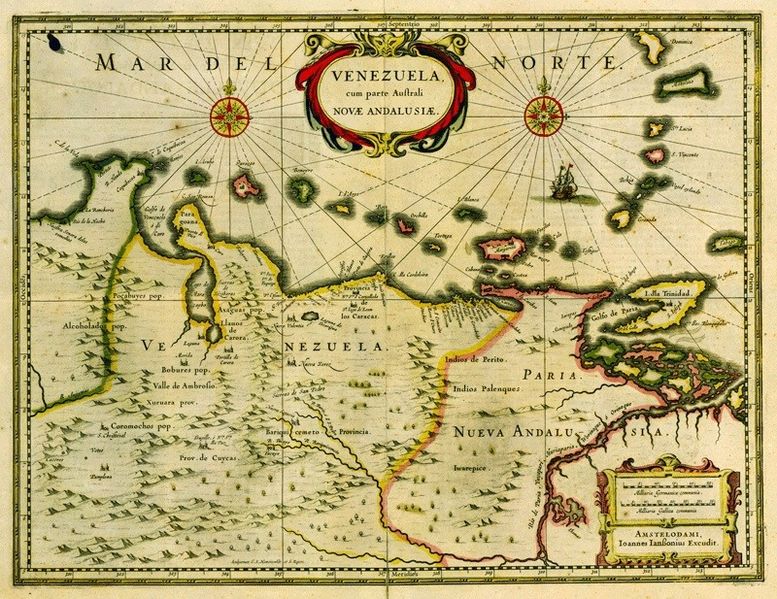

In colonial Venezuela, agricultural production was a distinctive activity, where the manufacture of cocoa represented an economic profitability. This changed with the oil dependence that occurred at the beginning of 1920, generating an exodus of Venezuelans to urban areas, leaving the fields and consequently agricultural development was affected.

With the conceptual emergence of Sustainable Development, the use of renewable resources becomes imperative and must be efficient, allowing the preservation of biodiversity with a social conscience without leaving aside the acquisition of money in exchange for products.

In this sense, environmental deterioration arises as a problem and the waste generated by crops must be transformed and reused using appropriate techniques to treat such waste, in order to reduce damage to soil, air, water, among others.

That is why, contributing to the development of alternatives that improve the country's economy without leaving aside environmental responsibility, we propose the creation of an antimicrobial agent based on one of the most representative residues in terms of its quantity produced after the post-harvest work in the crops of Theobroma Cacao L, such as the husk or cob; due to the chemical substances they contain, among which theobromine, caffeine and theophylline stand out, which have a bactericidal action inhibiting the multiplication of bacteria whose main transmission vectors are food.

THEOBROMA CACAO L, AS A TRADE EXCHANGE

Originally the Greek word Theobroma means drink of gods, also the scientific name is placed an L ending because it is the initial of the surname of Charles Linnaeus, who was the researcher who classified the plant for the first time according to Enriquez, (1985). Theobroma cacao L or Cacao Porcelana as it is known is a fruit that belongs to the Esterculiaceae family and is grown mainly in tropical countries such as Ecuador, Mexico, Brazil, Venezuela and others.

In Venezuela, the production of this fruit dates back more than 400 years and was used as a currency of exchange, it marked the social stratification of the population at that time, the owners of cocoa production units with large areas of land were the landowners who used slave labor in the production of their items.

Fig. 2. Map of colonial Venezuela. Author: Joannes Janssonius Excudit

Likewise, it is imperative to highlight that Theobroma cacao L, was the first Venezuelan export fruit, which together with coffee, was known as the Black Gold of the time, due to the wide varietal productivity of these species and the economic benefits that could be obtained by using them. This allowed Venezuela to become the first world producer of cocoa, becoming the main source of income during a long period of the colonial era.

At present, Venezuela does not export this product on a large scale; it stands out among the cocoa producing countries, since in its territorial extension there are several species such as Criollo, Trinitario, Forastero, Porcelana, Guasare, Chuao, among others, the latter products being valued internationally for the exquisite organoleptic characteristics derived from them, (Fundacite Zulia, 2010).

AGRICULTURAL ASPECTS

CONSIDERATIONS FOR PLANTING

Like any fruit, cocoa requires minimum conditions for its growth and development, so it must be planted in microclimates adapted for this work. Some considerations that should be taken at the time of planting is that the cocoa tree is susceptible to high concentrations of photon flux which are between 400-600 μmol m-2 s-1. This value represents approximately 30% of the solar radiation that could be received on a clear day according to (Balasimha et al., 1991; Raja Harun and Hardwick 1987; Barrera, 2006; Vespa, 2008).

It should be noted that the light intensity around the Theobroma Cacao L seedlings acts on other determining microclimatic factors such as temperature, relative humidity, evaporation and water availability in the soil; it also has a strong influence on the fertility of the plantation and leaf litter incorporation rates, which together affect both fruit growth and production.

Another parameter that should be considered at the time of planting is the variability of temperature, which directly influences the increase in dry weight of seedlings and stomatal conductances, which is why, depending on the cocoa to be cultivated, it can range between 20-33ºC, according to (Jaimez et al. 2008). In addition, for the absorption of nutrients by the roots of the tree to be efficient, it is necessary to have the availability of water for the processes of osmosis and later, with the help of solar radiation, photosynthesis.

Plant morphology

Complying with the factors mentioned above the plant can reach a height ranging from 6 to 20 meters with a tap root, which grows straight downward; immediately below the collar, most secondary roots develop about 15 to 20 cm deep in the upper portion of the soil layer. The taproot does not develop in asexually propagated seedlings; instead, primary and secondary roots are generated and grow horizontally.

The same author states that during their formation and growth, the leaves exhibit different pigmentations, are completely green, with simple, entire lamina, ranging in shape from lanceolate to almost oval. They are attached to the trunk or branches by means of petioles, those of the tree being longer. Their size varies depending on genetic traits, for example the Criolla variety has a larger foliage than the Forastero variety.

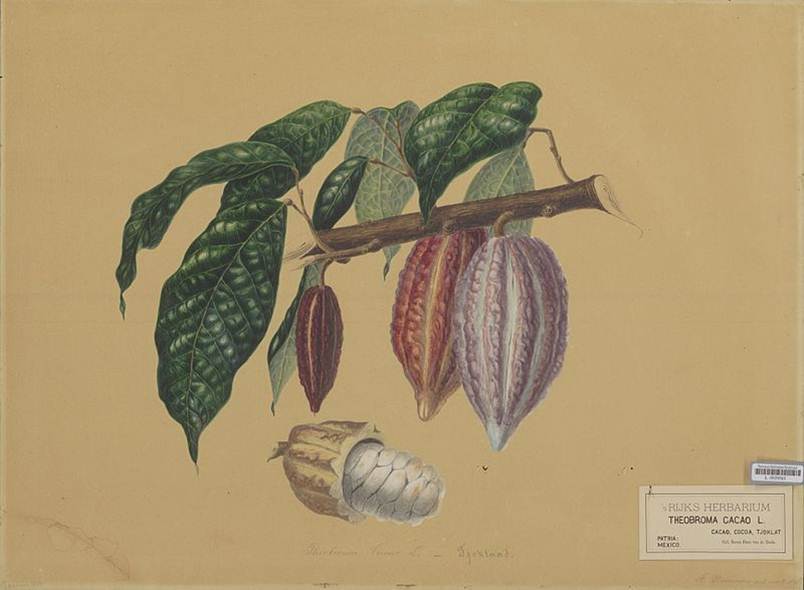

Its flowers are made up of five petals; when fertilized, they produce a drupe known as a pod. There are several factors that determine the size and shape of the fruit, among these are the genetic characteristics, the environment where the tree develops, as well as the management of the plantation.

The fruit of Theobroma Cacao L, has several constituent elements, among which the following stand out:

1. Cocoa pod shell, which is the covering or external part of the item, varies in color depending on the degree of maturity or the variety of fruit that has been grown green, yellow, purple or orange.

2. Mucilage or pulp has a white color, acid-sugar taste and is found covering the seeds (Kaltvatchev, Garzaro, & Guerra, 1998) refer to the mucilaginous pulp is formed mainly by spongy and parenchymatous cells, this substance has a content of sugar sap (10-13%), pentoses (2-3%), citric acid (1-2%), and salts (8-10%). During the harvesting process of the cocoa beans (the export product), the pulp is removed by fermentation and hydrolyzed by microorganisms. These in turn are protected by a small brown film called husk.

3. Cocoa beans, whose size and shape vary according to the genetic variety present; in Criollo beans are 3 to 4 cm long, almost oval, elongated, white, pink or pale violet in color, and in the Forastera variety they are 2 to 3 cm long with flattened, rounded, purple-colored shapes.

Fig. 3. Theobroma Cacao L , fruits and seeds. Author: "> Bernecker, A

CROP WORK

After planting, it is necessary to carry out various phytosanitary tasks such as programmed pruning, fertilization, elimination of pests and diseases, among others, to maintain the crop in optimal conditions. The period of time to wait from the foundation of the crop until the first harvest of the cobs varies between 5-6 years depending on the conditions mentioned above and the genetic material being cultivated; the harvesting of fruit trees can be done manually or mechanically.

Due to various cultural aspects, harvesting in Venezuela takes place during two periods per year; the first begins in September and ends in December, and the second begins in March and ends in May. The harvested fruits are cut manually and placed in baskets in the cocoa plantation, then they are split separating the shell from the seeds, this process is called shelling, and then they are fermented.

Several authors state that if the time between harvesting and shelling is delayed, the temperature will increase drastically during the fermentation process, decreasing the yield of by-products, which leads to a reduction in the final sensory characteristics. This time varies depending on the area where the material is grown and is between 5-15 days; during this time the sensory characteristics of cocoa such as aroma and flavor are developed, which is why they are essential during the production of products derived from this item.

Fig. 4. Cocoa beans suitable for chocolate preparation. Author: Electrolito

FRUIT TREATMENT

Once the fruit is obtained, it must go through a fermentation process, this procedure benefits the Theobroma Cacao L, this reaction is performed by increasing the temperature of the cocoa beans which are still attached to the mucilage, subsequently generating the migration of certain acids located in the pulp. This process prevents the beans from germinating, increases their volume and turns them dark.

The fermentation of the almonds consists of depositing those that were extracted from the fruit in wooden boxes, baskets or barrels designed for this process. These fermenters are stacked to keep the temperature of the matrix constant and to achieve an efficient process; it is also necessary to stir the crates continuously with preferably wooden tools so that the reactions develop uniformly.

According to Schwan, Rose, & Board, (1995), microorganisms play a fundamental role in the fermentation process, they appear in the following order, first yeasts, then lactic acid bacteria and finally acetic acid bacteria. This process involves two phases, one anaerobic in the total absence of oxygen and the other aerobic which requires this element for its progress, which are essential for the proper development of the characteristics of cocoa.

According to Schwan, Rose, & Board, (1995), the anaerobic phase is carried out by lactic acid bacteria and yeasts, whose main metabolites are ethanol and lactic acid. These microorganisms contribute to the breakdown of the citric acid present in the mucilage, causing an increase in pH from 3.5 to 4.2. The acidity generated in the cocoa beans and the rise in temperature that occurs in the mass, originates the hydrolysis of proteins in the cotyledons by the bacteria, their contribution is of utmost importance for the formation of flavor precursors, such as reducing sugars, pyrazines and free amino acids.

With respect to the aerobic phase, it is carried out for the formation of acetic acid from ethanol using acetic acid bacteria. After the decrease in yeast population and with the increase in pH and the reduced viscosity that arises during the anaerobic phase, the fermenting mash becomes much more aerated.

Temperature monitoring during the cocoa fermentation process is therefore of utmost importance as it represents an indicator of the degree of fermentation that is being achieved.

An increase in temperature is caused by the exothermic reactions and the microbial activity that occurs, the heat generated comes from the oxidation of ethanol to acetate and the conversion of acetate to CO2 and water (Cros & Jeanjean, 1995).

After fermentation, drying takes place; the main objective of this stage of the process is to eliminate excess moisture from the grains, from 60% to 8%, mainly by exposing them to solar radiation. Another aspect to take into account is storage, which must be carried out in places that do not have strange odors and dry to avoid the proliferation of fungi and insects.

SYSTEM OF UTILIZATION FOR THEOBROMA CACAO L SHELL: ANTIMICROBIAL AGENT

An antimicrobial agent is defined as a product designed to reduce or prevent the growth and massification of bacterial or fungal colonies that are considered harmful and represent a potential health risk.

There is a great variety of substances that have this inhibitory behavior, classified depending on their chemical composition and the damage they may cause to the functional structures of a particular microorganism, resulting in its death.

At present, research is being developed that affirms the extraction of natural antimicrobial agents obtained from plants, trees, fruits, parts of these; some of them, such as lysozyme and niacin, these chemical compounds have the same inhibitory capacity against microorganisms as those elaborated synthetically, which represent an innovative alternative not only to ensure an effective and efficient conservation of food but also to promote the reuse of vegetable waste for this purpose, reducing the use of harmful chemical substances to a great extent and collaborating with environmental preservation.

As mentioned above, one of the organic residues containing numerous usable chemicals such as theobromine, caffeine and theophylline is the shell or epicarp of Theobroma Cacao L, which is why it is intended to have these antimicrobial properties specifically on Gram-positive bacteria harmful to food as Bacillus cereus and Streptococcus agalactiae, for the development of a liquid plant extract that can be used in the food industry, and that also allows producers to improve the perceived profits of their crops while contributing to the preservation of the environment.

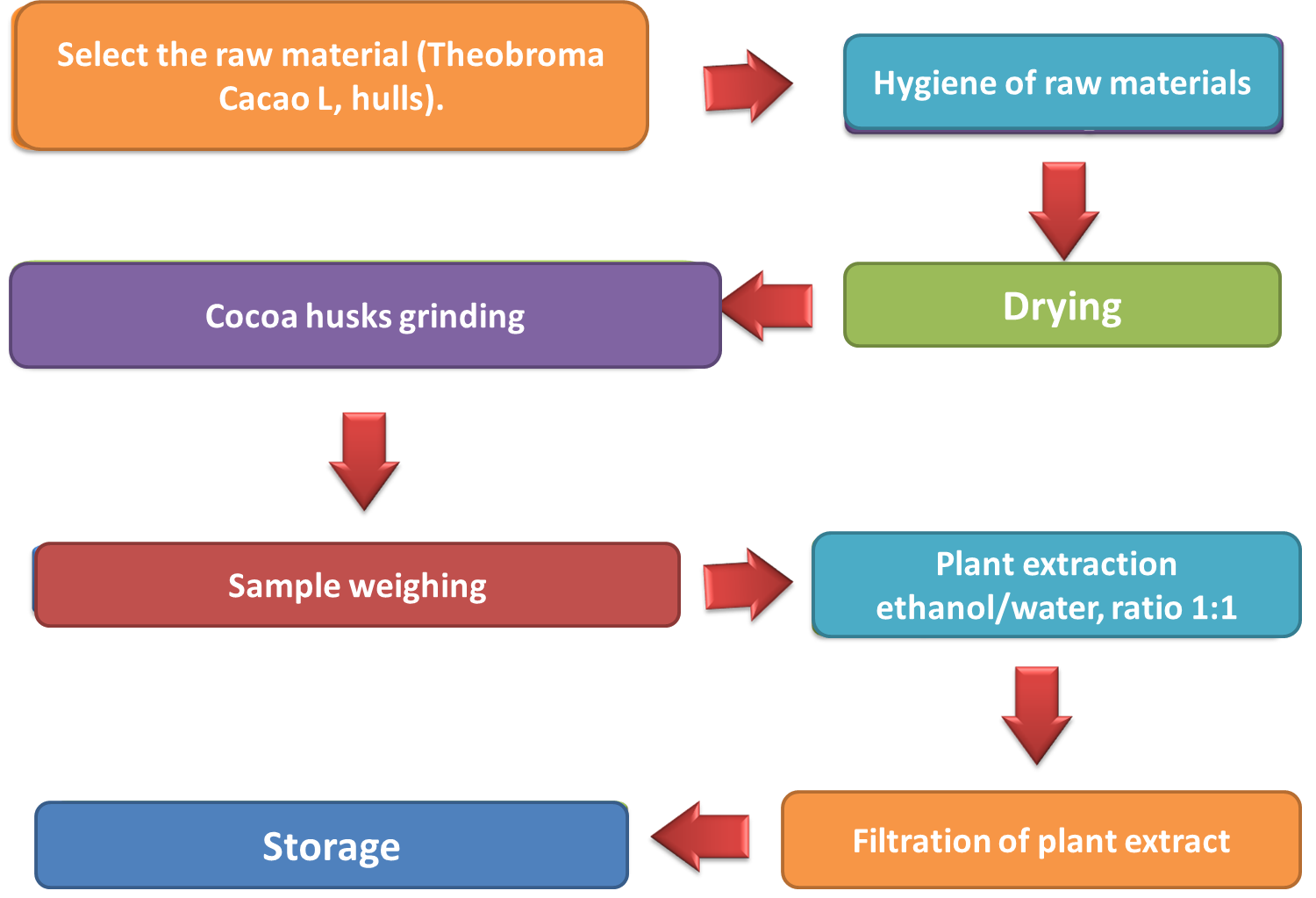

The following is the proposed flowchart for the development of the vegetable extract based on the shell of Theobroma Cacao L, which due to its antimicrobial properties is proposed as an alternative agro-input in these times of crisis, it is also a profitable option for cocoa farmers would be a more environmentally friendly way contributing to environmental preservation.

Fig. 5. Process for obtaining the vegetable extract based on the shell of Theobroma Cacao L. Author: @madridbg, adapted from Cuéllar and Guerrero (2012).

To obtain the extract, the following methodology must be followed:

1. Selection of the raw material (shells of Theobroma Cacao L ): The cobs must present a state of optimal maturation that is to say post-harvest, in addition they should not be mistreated, necrotic or infected with any disease because there would be a variation in the concentrations of the substances of interest.

2. Hygienization of the raw material: After the selection of the peels, they should be cut into pieces and scalded either by introducing them into a solution of citric acid at 1% or sodium hypochlorite at the same concentration for 5 minutes at a temperature of 75 ºC ± 2ºC.

3. Drying: After that, the pieces will be taken to an oven with air circulation for 24 hours, until the humidity of the sample is reduced to 8% ± 1%.

4. Milling of the Theobroma Cacao L shells: The size of the sample is reduced with a mill until reaching a particle size of approximately 40 mesh.

5. Weighing of the sample: Authors such as Cuellar and Guerrero (2012) recommend weighing approximately 20-25 grams of the powder obtained after the grinding process, for subsequent elution with solvents. It is recommended to perform a degreasing with hexane prior to treatment.

6. Vegetable ethanol: water extraction: The extractions or separations are carried out depending on the nature of the substances to be extracted from the vegetable matrix, and must be done in two phases, the first being the alkaloidal part and the second the phenolic phase. In the case of the peel, individual organic solvents such as chloroform, ethyl acetate, and n-butanol can be used in addition to developing aqueous extracts and mixtures with, for example, absolute ethanol-water in a 1:1 ratio. Such a procedure should be carried out using magnetic stirring for 2 hours at an average temperature of 25°C.

7. Filtration of the plant extract: After extraction, it is necessary to separate the substances, preferably using No. 4 filter paper; filtration should be carried out under vacuum to ensure the innocuousness of the procedures.

8. Storage: Both the liquid extract and the organic phase obtained after filtration should be reserved in amber colored bottles to ensure that they are protected from light and should be stored at a temperature of 4ºC. (Cuellar and Guerrero 2012)

FINAL CONSIDERATIONS

It is important to point out that human beings present a creative capacity that allows them to continue in the constant exploration of alternatives in the face of adverse situations that adjust to current needs; In its tireless search, the versatility of Theobroma Cacao L, is evident. It is necessary to carry out research of this kind in Venezuela that will allow diversifying the use of this product not only for the elaboration of agricultural inputs, but also for the development of personal hygiene products, manufacture of food preservatives, thickeners, gelling agents, among other additives that improve the characteristics and increase the profits perceived by farmers.

It should be emphasized that the development of the antimicrobial agent is a feasible option due to the availability of the raw material necessary for this purpose, i.e. Venezuelan producers waste approximately 180,000 metric tons of Theobroma Cacao L shells per year, which could be used not only for the creation of the agro-input, but also to continue encouraging research in the agri-food field.

Inputs that combat pathogenic microorganisms are developed synthetically in laboratories and require the extensive use of harmful chemicals, in addition these compounds have a smaller supply in the domestic market, which is why this organic alternative arises using waste that would be favorable for the preservation of the planet innovating in a positive way in the generation of an environmental society and managing to develop products with a Venezuelan seal.

In spite of being a natural product, the lack of knowledge can cause certain distrust on the part of the consumers, that is why it is necessary to make people aware of the benefits of the same, it is necessary to deepen in the properties of the developed agent, characterizing to determine its structure and functionality.

Venezuela requires training, innovation and investment of its people to promote the development of research to take advantage of all the waste generated in the work of benefit and post-harvest by the cultivars that occupy much of the national territory, as the Theobroma Cacao L, Cocos nucífera wide variety of musaceae, tubers, cereals among others that contribute to the transformation of the country into an international power based on agro-sustainable policies framed in the new model of national production.

It is necessary that the country evaluates options for the generation of inputs coming not only from plants, but also to encourage to continue with the investigation of so many benefits that nature offers and sometimes, due to ignorance or scarce economic resources, prevent us from seeing them.

Therefore, it is necessary to detect the productive capacities of the country and strengthen the system in the agri-food area and research, in order to promote the engines implemented by the Executive in the Bolivarian Economic Agenda to overcome the current economic situation.

BIBLIOGRAPHY CONSULTED

[1] Balasimha, D., Daniel, E., & y Bhat, P. (1991). Influence of environmental factor son photosynthesis in cocoa tres. Agricultural and Forest Meteorology , 55, 15-21.

[2] Barazarte, H., Sangronis, E., & Unai, E.(2008). strong> La cáscara de cacao (Theobroma cacao L.): una posible fuente comercial de pectinas. Archivos Latinoamericanos de Nutrición; , volumen 58: 1, pag: 64-70. Article: Online Access

[3] Barrera, G. (2006).strong> Respuestas de la clorofila y la fotosintesis al deficit hidrico y diferentes condiciones de luz en dos varierdades de cacao Theibroma cacao L. Article: Online Access

[4] Córdova, V., Sánchez, M., Estrella, N., Macías, A., Sandoval, E., Martínez, T., y otros. (2001). strong> Factores que afectan la producción de Cacao (Theobroma cacao L.) en el Ejido Francisco I Madero del plan Chontalpa Tabasco, México. Universidad y ciencia; , 93-100.. Article: Online Access

[5] Córdova, V., Sánchez, M., Estrella, N., Macías, A., Sandoval, E., Martínez, T., y otros. (2001). strong> Factores que afectan la producción de Cacao (Theobroma cacao L.) en el Ejido Francisco I Madero del plan Chontalpa Tabasco, México. Universidad y ciencia; , 93-100.. Article: Online Access

[6] Cros, E., & Jeanjean, N. (1995).strong> Cocoa quality: effect of fermentation and drying. Plantations, recherche, développement .. Article: Online Access

[7] Jaimez, R., Tezara, W., Coronel, I., & Urich, R. (2008). Ecofisiología del cacao (Theobroma cacao): su manejo en el sistema agroforestal. Sugerencias para su mejoramiento en Venezuela. Revista forestal venezolana , 52 (2), 253-258.

[8] Kaltvatchev, Z., Garzaro, D., & Guerra, F. (1998). Theobroma cacao L: Un nuevo enfoque para nutrición y salud. AGROALIMENTARIA .

[9] Schwan, R., Rose, A., & Board, R. (1995). Microbial fermentation of Cocoa Beans, With Emphasis on Enzimatic Degradation of the Pulp. Journal of Applied Bacteriology Simposium Supplement , 965 – 1075.

OF INTEREST

For more information related to the areas of science, technology, engineering and mathematics, do not hesitate to visit #stemsocial and #stem-espanol, they are communities that promote scientific advances in these areas

0

0

0.000

https://twitter.com/BGMadrid/status/1358188175458500609

#posh twitter

https://twitter.com/BGMadrid/status/1358188175458500609?s=20

The quantities wasted are enormous. I have heard that many people make sweets with the peel, but at home. It could be industrialized and thus take advantage of this resource, it could also be used to make some kind of liquor.

Greetings @cryptoxicate, thanks in advance for stopping by and leaving your comment, there are certainly many uses that can be given to this waste and we at UNESUR are giving a second use to these materials.

Thanks for your contribution to the STEMsocial community. Feel free to join us on discord to get to know the rest of us!

Please consider supporting our funding proposal, approving our witness (@stem.witness) or delegating to the @stemsocial account (for some ROI).

Please consider using the STEMsocial app app and including @stemsocial as a beneficiary to get a stronger support.