Electric Spray Colors Complex 3D-Printed Objects

Nowadays, 3D printers can create almost anything out of anything. But when it comes to coloring the 3D printed object that is not as easy.

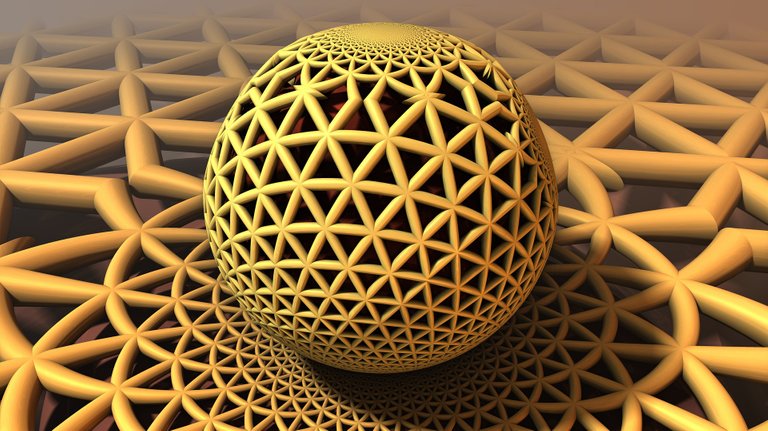

Image by Pete Linforth from Pixabay

- Be also sure to check out my other posts and follow me @kralizec and subscribe to my Youtube channel at Kralizec Gaming Youtube Channel

3D printers can create amazing things. And some 3D printed objects can have such a delicate and complex structure that it's even hard to just comprehend how such an object got created. Without 3D printing, we could completely forget about making them. But the problems comes whenever we want to color them or cover them with some more functional material without wasting a lot of material, time, and finance.

The Problem of 3D Coloring

Jonathan Singer from Rutgers University in America came up with a new method that will easily and effectively color even the craziest of 3D printed objects. Singer's team borrowed the already existing technology called electrospray deposition and altered it to use on 3D printed objects.

The trick in electrospray deposition lies in the fact that a fluid with the desired material passes through a nozzle and the tiny droplets create a mist that gets electrically charged because of an electric field created by a high voltage current. The electrically charged micro-droplet mist attaches itself to any surface it comes into contact with.

In this past, this technology was used – for example – in the creation of surfaces that have vaccines in them or inside of solar panel cells in the layers that absorb light. The team from Rutgers University applied films of polymer materials onto complex 3D printed objects made from different kinds of materials.

This incredible way of coloring 3D printed objects allows us to color or add a film onto an incredibly delicate material such as a hydrogel. Such 3D printed hydrogel objects can increase in size when they absorb water or shrink when they release it but the colored surface will stay untouched. At the same time, it is an economical method because only a small amount of the material applied gets used.

Singer and his colleagues are now developing a device that could be added to already existing 3D printers. If they succeed then we could create colorful or even useful surfaces on top of 3D printed objects easily and cheaply. And because the technology is cheap and economical it could find its use even outside of the realm of 3D printing. It could be used to apply special nanoparticle or bioactive coatings to surfaces where using traditional methods would be too expensive or wasting the coatings because less economical methods need more of them is not an option.

Sources:

- https://www.rutgers.edu/news/great-new-way-paint-3d-printed-objects

- https://pubs.acs.org/doi/full/10.1021/acsami.9b23544

- If you like the content I’m producing about science maybe you will like the content I produce about gaming as well! Be sure to check out my other posts!