Bioplastics: know the types there are

This industry is growing every day, slowly but steadily; last year 3.8 million tons of bioplastics were produced, which represented a growth rate of 3%, and some experts predict that by 2024 they could maintain this rate [1], although it seems little, it is almost the same growth rate of synthetic plastic products. So it is not unreasonable to think that in the future bioplastics could replace conventional plastics in the production of any article made of this type of material today.

Thanks to the development of this industry there is a great variety. Source: Image designed by @emiliomoron.

Thanks to the research and development of this type of bio-based material, which goes back a few decades, today there is a wide range of compounds that have found a specific application according to their characteristics. Some materials are rigid and others flexible, some are biodegradable, others can be compostable and some decompose as slowly as conventional plastic, so when we talk about this type of material it can be confusing, so we are going to review some concepts that allow us to clarify a little the types of bioplastics that exist.

What are bioplastics?

Let's remember that this term is used to refer to any plastic material that is made from renewable organic sources, generally vegetable, such as corn starch or cellulose. Unlike conventional plastics that are derived from the polymerization of petroleum-based compounds. So they have clear ecological advantages over these to help us erase our footprint on the planet.

They are bio-based and biodegradable materials. Source: image designed by @emiliomoron.

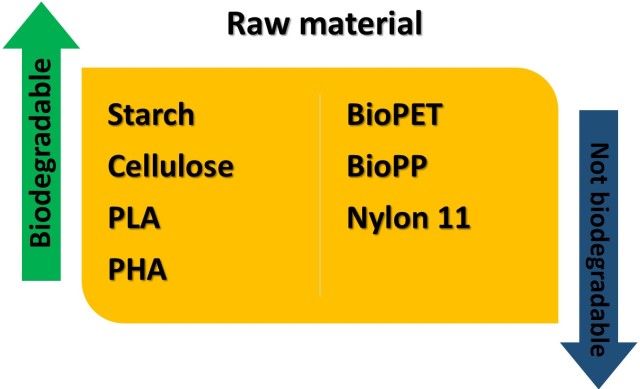

Types of bioplastics

Bioplastics comprise a large category of biopolymers with different attributes and applications, obtained from biomass. And thanks to research into new materials and other sources of raw materials, the list is constantly expanding. The different compounds can be classified according to their origin and in turn whether they are biodegradable or not.

Classification of bioplastics according to their biodegradability. Source: image designed by @emiliomoron.

The most common ones we can find include:

Biodegradable

This family of bioplastics are those that come from vegetable materials and can be naturally degraded by microorganisms. Among them we can find:

Bioplastics based on starch:

It is a simple bioplastic derived from corn starch. It is a macromolecule that is composed of two different glucose polymers, amylose (in a proportion of 25%) and amylopectin (75%)[2]. The production of the biodegradable plastic from starch begins by extracting it from corn, then microorganisms are used to transform it into a smaller molecule of lactic acid that serves as a base for the elaboration of polylactic acid (PLA) polymer chains. The intertwining of these chains results in a plastic sheet that serves to elaborate several less contaminating plastic products[3].

Cellulose-based bioplastics:

Produced with cellulose esters and cellulose derivatives. The most common examples are cellophane and cellulose acetate. Cellulose is a polysaccharide complex with a crystalline morphology, chemically it is similar to starch since it is also a glucose polymer. The most commonly used cellulosic polymers in the manufacture of plastics are cellulose acetate (CH3COOC2H5), manufactured from the reaction between cellulose and acetic acid; cellulose acetate butyrate, which is a compound ester produced by treating cellulose fibers with butyric acid, butyric anhydride, acetic acid, and acetic anhydride, and cellulose nitrate, manufactured by treating cellulose fibers with a mixture of nitric acid and sulfuric acid[4].

Polyhydroxyalkanoates:

Also called PHA, they are linear polyesters produced in nature by the action of bacteria through the fermentation of sugar or lipids. More than 150 different monomers can be combined to give this type of materials with extremely different properties. PHA polymers are thermoplastic, they can be processed in conventional processing equipment, and depending on their composition they can be ductile and more or less elastic[5].

Polylactic Acid:

Or PLA, is a thermoplastic aliphatic polyester made up of elements similar to lactic acid, it can also be obtained from corn starch. It has mechanical properties similar to PET, but has a significantly lower maximum use temperature, this compound can be processed, like most thermoplastics, into fiber and film[6].

Table n° 1. Some characteristics of biodegradable bioplastics.

| Biopolymer | Raw material | Source | Properties | Substitute for |

|---|---|---|---|---|

| Starch based | Starch | Corn, potato, cassava | Low water vapor barrier. Regular mechanical properties. Fragility | polystyrene |

| Cellulose based | Cellulose | Wood Pulp, Cotton | Low water vapor barrier. Fragility | polypropylene |

| Polyhydroxyalkanoates: | Starch | Corn, potato, vegetable oils | Improved water vapor barrier properties. Good oxygen barrier properties. Sufficient fat and odour barrier properties | Polyethylene. Polypropylene |

| Polylactic Acid | Lactic acid | Corn (mostly). Sugar beets. Potatoes. Wheat. | High resistance to tension. Fragility. Low crystallinity. Low thermal stability. | Polyethylene Terephthalate (PET). Polypropylene. Polystyrene |

Not biodegradable

The fact that a plastic is made from renewable raw materials does not necessarily mean that it is biodegradable. This is the case of these materials whose chemical structure cannot be broken down by microorganisms, although they are mechanically recyclable:

Organic polyethylene:

Also called biopolyethylene (BIOPE), this compound is made from ethanol, which is converted from ethylene after a dehydration process, and can be made from various raw materials such as sugar cane, sugar beet and wheat grain. The final product is identical to that derived from petroleum and natural gas, thus maintaining the physical properties for transformation into plastic products[7].

Biopolypropylene:

As with BIOPE, propylene can also be obtained from renewable raw materials, and using conventional polymerization techniques, biopropylene (BIO-PP) is obtained, with identical characteristics to those of the petroleum derivative.

Nylon 11:

Or polyamide 11 (PA 11) is a polyamide, a bioplastic member of the nylon polymer family, produced by the polymerization of 11-aminoundecanoic acid. It is produced from Arkema's castor beans under the trade name Rilsan[8].

Table n° 2. Some characteristics of non-biodegradable bioplastics.

| Biopolymer | Raw material | Source | Properties | Applications |

|---|---|---|---|---|

| Biobased polyethylene | Bioethanol | Sugar cane | Identical to the oil derivative | Bags, films and bottles |

| Biobased polypropylene | Bioethanol | Sugar cane | Identical to the oil derivative | Packaging. Films. transparent. Automotive components. Fabrics |

| biopolyamide | 11-aminoundecanoic acid | Castor oil | Flexible. Resistant to UV rays. Smooth. Resistant to grease. | Flexible pipes. Fuel pipes. Clamps. Automotive components. |

Conclusion and contributions

As we have seen, bioplastics are made from renewable raw materials, which may or may not be biodegradable. The list of bioplastic compounds is extensive, and in it we can find variants of conventional plastics, such as polyethylene and polypropylene, which can be derived from oil as well as from vegetable sources, and although their origin is different, the chemistry of the molecule is the same.

Therefore, with this classification I have tried to describe which are some of the bioplastics available in the market, helping to clarify that the use of the term "bio" does not necessarily make all these materials biodegradable, so as they are incorporated into the market it is important to have this clear, in order to give them an adequate disposal, either composting or recycling according to their type.

Well friends, I hope the information has been to your liking and is useful, as there are many terms to know in the world of bioplastics, until next time!

References

- Mundoplast.com (2020). La producción de bioplásticos creció un 3% en 2019.

- Wikipedia.com. Almidón.

- Wikipedia.com. plástico biodegradable.

- Textoscientificos.com. Polímeros celulósicos.

- Wikipedia.com. Polihidroxialcanoatos.

- Tecnología de los plásticos. Poliácido láctico.

- Wikipedia.com. Bio-polietileno.

- Wikipedia.com. Nylon 11

Thanks for your contribution to the STEMsocial community. Feel free to join us on discord to get to know the rest of us!

Please consider supporting our funding proposal, approving our witness (@stem.witness) or delegating to the @stemsocial account (for some ROI).

Please consider using the STEMsocial app app and including @stemsocial as a beneficiary to get a stronger support.

Thanks for the support my friends!