PEMFC fuel cells (Part 3): Diffusion layers with regulated characteristics.

PEMFC fuel cells: Improvements and Difficulties.

PEMFC fuel cells: Improvements and Difficulties (Part-2)

Diffusion layers with regulated characteristics:

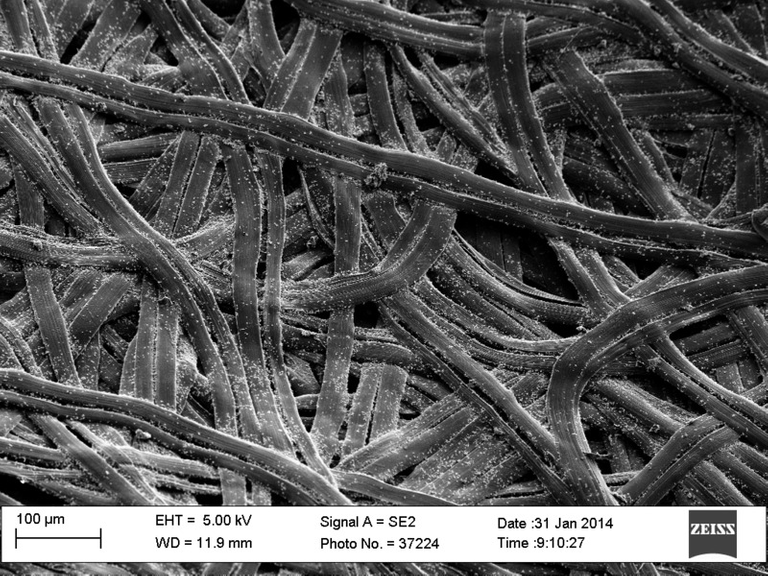

The diffusion layer is made up of a binder in the form of fabrics with pore sizes in the range of 1 to 10 μm, and a carbon fibre support. A microporous deposit is frequently applied, this has pore diameters of 10 nm to 1 μm, porosities on the order of 0.4 to 0.5, and is made up of carbon granules and a binder.

Carbon fibers from silk cocoon

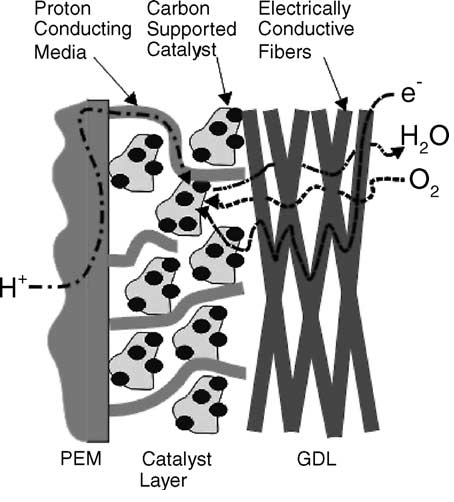

Reactive gases must go from the channels to the active layer, and this is what the diffusion layer is in charge of assuring. It serves three purposes:

1- Make the membrane and the active layers subject to a variety of mechanical assembly stresses.

2- Move electrons between the distributors' teeth and the active layers.

3- Purge the cathode of the heat and water generated there.

Transport of Gases, p+ and e- in PEMFC.

The diffusion layer makes it possible to create a gradient of pore sizes between the Nano-dispersion catalyst and the gas supply at the inlet of the cell, thus creating a homogeneous operation of the active layer. Furthermore, depending on the operating conditions and the properties of the components, the diffusion layer will play an important part in the management of the water contained in the cell's core, whether in the form of vapor or liquid. In order not to clog the pores, the liquid water is evacuated towards the gas distributors, and retains sufficient quantities at the level of the active layer and the membrane.

Recent research demonstrates that by changing the layers functionalization and structure, improvements are still achievable. Achieving multi-layered porous structures, adaptable to heterogeneity in the presence of canals and teeth, is among the challenges that researchers seek to address. In addition, they are working on regulating the spatial distribution of the carbon fibres.

The diffusion layer's crucial influence on the stress distribution in the stack should also be emphasized, to sum up, the mechanical characteristics of the diffusion layer must be considered because of how it affects both performance and longevity.

References:

Les matériaux au cœur du processus d'innovation- Clefs CEA No 59 – Publication: Summer 2010.

Maiyalagan T, Pasupathi S. Components for PEM Fuel Cells: An Overview. MSF 2010;657:143–89.

Thanks for your contribution to the STEMsocial community. Feel free to join us on discord to get to know the rest of us!

Please consider delegating to the @stemsocial account (85% of the curation rewards are returned).

You may also include @stemsocial as a beneficiary of the rewards of this post to get a stronger support.

Congratulations @benainouna! You have completed the following achievement on the Hive blockchain And have been rewarded with New badge(s)

Your next target is to reach 800 replies.

You can view your badges on your board and compare yourself to others in the Ranking

If you no longer want to receive notifications, reply to this comment with the word

STOPCheck out our last posts:

Support the HiveBuzz project. Vote for our proposal!