Chemistry of Glass "Part 10": Factors that make cold crucible vitrification intriguing!

There has been development of a new method for making glass using direct induction in a cool crucible. The glass to be melted is placed in an alternating electromagnetic field generates by an inductor to perform direct induction melting, through the Joule effect, the induced currents produced by the alternating electromagnetic field lose power. The crucible, which is constructed of a metal like stainless steel, is segmented and cooled by water circulation.

Menlo Lab Crucibles

Between 5 and 10 mm thick, a small layer of frozen glass develops in contact with the cold wall, which causes the cold metal on the wall and the molten glass to separate. To start the induction process, a titanium (Ti) or zirconium ring must be placed on the initial glass charge, the electromagnetic field causes this ring to heat up, then the glass is able to melt due to the energy provided by its oxidation.

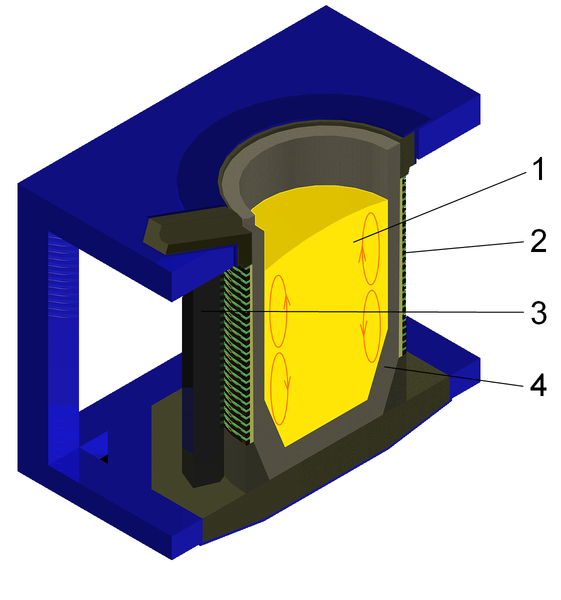

Section view of a coreless induction furnace: 1- melt. 2- water cooled coil. 3- laminated yokes. 4- crucible.

Using a cooled metal valve, the glass is poured, and in order to maintain induction and continue melting, an amount of molten glass is kept inside the furnace.

In between the molten glass and the crucible, a thin layer of frozen glass develops. Corrosion is halted as a result. Also, the ability to produce glass and reach high temperatures increases when direct induction heating technology is used in the molten glass bath. To take use of these two fundamental qualities, furnaces for making glass by induction in a cold crucible have been developed in the context of nuclear applications.

References:

- CHARACTERIZATION OF THE R7T7 LWR REFERENCE GLASS- PACAUD F.- FILLET C.- BAUDIN G. CEA Centre d'Etudes Nucléaires de la Vallée du Rhône, 30 Bagnols-sur-Ceze ^FR

- [General and inorganic chemistry book- M. Shkhashirou- H. Birqdad- Y. Qodsi- University publications. Algeria]

- Glass and Ceramic Technology Course (2021). Professor Khelifa- Department of Materials Process Engineering- University of Mostaganem. Algeria.

- Les matériaux au cœur du processus d'innovation- Clefs CEA No 59.

- Neumann, Florin. "Glass: Liquid or Solid – Science vs. an Urban Legend". Archived from the original on 9 April 2007. Retrieved 8 April 2007.

- Helène Tregouët. Structure et cristallisation de verres d’oxydes simples riches en bore et en terres rares. Chimie-Physique [physics.chem-ph]. Université Pierre et Marie Curie- Paris VI, 2016. Français. NNT: 2016PA066032. tel-01358710.

Thanks for your contribution to the STEMsocial community. Feel free to join us on discord to get to know the rest of us!

Please consider delegating to the @stemsocial account (85% of the curation rewards are returned).

You may also include @stemsocial as a beneficiary of the rewards of this post to get a stronger support.