Effect of Carboxyl Methyl Cellulose (CMC) on Local Clays (Full Data Analysis) || An Original Research

This then prompted the beneficiation of the local clays with carboxyl methylcellulose, barite and soda ash so as to improve their properties. However, this post covers only the effect of carboxyl methylcellulose as an additive to the formulated drilling fluid. Table 1.0 below shows the natural (unbeneficiated) properties of the local clays and that of bentonite.

It should be noted that clay deposits were being obtained from two locations namely; Efiat Offot and Afaha Oku. Part of the research objective was to determine the properties of these local clays and that was done using the relevant materials, equipment/ apparatus.

For density determination, the mud balance was being used; for pH value determination, the pH metre was being employed. In determining the filtrate volume of the local clays, the Low-Temperature Low-Pressure (LTLP) Filter Press was being used whereas the sand content kit and the Fann V-G Viscometer was being used in determining the mud sand content and their rheological properties (gel strength, plastic and apparent viscosity) respectively.

Table 1.0: Summary of the Properties of Bentonite and the Local Clays

| Clay Properties, Units | Standard Bentonite | Afaha Oku Clay | Efiat Offot Clay |

|---|---|---|---|

| Density, Ib/gal | 8.9 | 8.2 | 8.4 |

| Specific Gravity | 1.07 | 0.99 | 1.01 |

| pH Value | 10.60 | 5.15 | 5.42 |

| 10secs Gel Strength, Ib/100ft2 | 4.00 | 0.98 | 1.00 |

| 10min Gel Strength, Ib/100ft2 | 8.00 | 1.90 | 2.00 |

| Yield Point, Ib/100ft2 | 10.00 | 1.50 | 2.54 |

| Apparent Viscosity, cP | 11.50 | 1.53 | 3.25 |

| Plastic Viscosity, cP | 6.50 | 1.70 | 1.98 |

| Sand Content, % | 0.29 | 0.52 | 0.44 |

| 10mins Filtrate Volume, mL | 14.60 | 205.3 | 262 |

| 30mins Filtrate Volume, mL | 30.00 | 5.8 | 4.4 |

Summary of the results of the rheological properties, pH value, density, sand content, specific gravity and fluid loss and of the local clays as well as that of bentonite were ascertained. A comparison of the Efiat Offot and Afaha Oku clay properties otherwise referred as local clays in this post with bentonite is presented in Table 1.0. From the results in Table 1.0, there is a significant and clear margin in the properties of the local clay muds and that of bentonite.

From the results in Table 1.0, the density of bentonite was 8.9lb/gal while that of Afaha Oku and Efiat Offot clay were 8.2lb/gal and 8.4lb/gal respectively. The specific gravity of bentonite was determined to be 1.07 while Afaha Oku and Efiat Offot clays had their specific gravities to be 0.99 and 1.01 respectively.

More so, the local clays had their pH values to be 5.15 and 5.42 while the pH value of bentonite was determined to 10.60. The results also revealed that the filtrate volume of bentonite at 10 minutes was 15.6mL whereas at the same minute, the Afaha Oku and Efiat Offot mud had filtrate volumes of 205.8mL and 262.6mL respectively.

From Table 1.0, the results further revealed that bentonite had a high plastic viscosity of 6.5cP when compared to those of Afaha Oku and Efiat Offot clays which were 1.7cP and 1.98cP respectively. Also, the results showed a very low apparent viscosity for both Afaha Oku clay which was 1.53cP and Efiat Offot clay which was 3.25cP.

On the other hand, the apparent viscosity of bentonite was 11.50cP. A yield point value of 10lb/100ft2 was obtained for bentonite while the local clays had yield point values of 1.50Ib/100ft2 and 2.54lb/100ft2. The results also showed an 8lb/100ft2, 1.90lb/100ft2 and 2.00lb/100ft2 gel strength (10mins) for bentonite, Afaha Oku and Efiat Offot clay respectively.

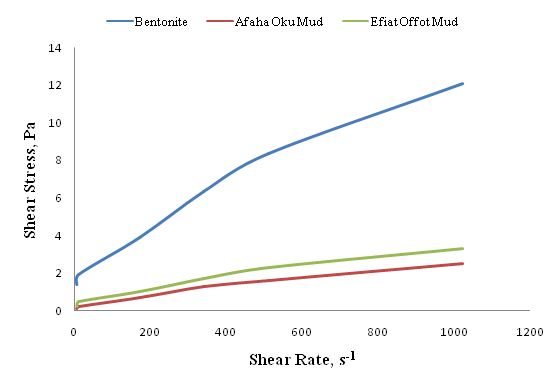

Figure 1.0: Shear Stress/Shear Rate Plot for Bentonite and the Local Clays

Furthermore, Figure 1.0 clearly shows the disparity in the rheological properties of the local clays and bentonite using the shear stress and shear rate plot.

The shear stress and shear rate plot depicts the flow pattern of a particular fluid, in this case, it shows how the respective formulated mud flows. From the figure above, the shear stress and shear rate plot for bentonite differs from that of the local clays. This however is due to the absence of sodium cations (Na++) in the local clays. The absence of this sodium cation further hinders the swelling tendency of the Efiat Offot and Afaha Oku Mud. This then explains the local clays' low shear stresses (Skalle 2010; Udoh and Okon, 2010).

Effect of Carboxyl Methylcellulose (CMC) on Fluid Loss of the Local Clays

So as to improve the performance of the local clays, carboxyl methylcellulose (CMC) was added as a fluid loss agent to the formulated mud using the local clays. This process of adding chemicals and other materials so as to improve mud properties is termed beneficiation. Summary of the results of the filtrate volume of both Efiat Offot and Afaha Oku mud with respect to their varying Carboxyl MethylCellulose (CMC) contents are shown in Table 2.0 and 3.0.

Table 2.0: Effect of Carboxyl Methyl cellulose Content on Efiat Offot Mud

| Clay Mud, Units | Sample A | Sample B | Sample C | Sample D | Sample E |

|---|---|---|---|---|---|

| CMC Content (g) | 8.58 | 17.16 | 25.74 | 34.32 | 42.9 |

| 10mins Fluid Loss, mL | 45 | 14.2 | 7.8 | 4.4 | 2.5 |

| 30mins Fluid Loss, mL | 20 | 7.0 | 5.2 | 4.8 | 3.6 |

| Plastic Viscosity, cP | 6.55 | 6.81 | 7.27 | 7.44 | 7.80 |

| Apparent Viscosity, cP | 9.11 | 9.63 | 10.57 | 10.90 | 11.92 |

| Yield Point, lb/100ft2 | 5.12 | 5.64 | 6.59 | 6.93 | 7.97 |

The results presented in Table 2.0 and 3.0 shows that the formulated drilling fluid’s filtrate volume at 10 minutes reduced significantly with increase in CMC content. From Table 2.0, the filtrate volume of Efiat Offot mud at 10minutes decreased from the initial 262mL to 45mL (about 83%) at a concentration 8.58g of CMC to 350mL of the local clay mud (Sample A).

Table 3.0: Effect of Carboxyl Methyl cellulose Content on Afaha Oku Mud

| Clay Mud | Sample A | Sample B | Sample C | Sample D | Sample E |

|---|---|---|---|---|---|

| CMC Content (g) | 8.58 | 17.16 | 25.74 | 34.32 | 42.9 |

| 10mins Fluid Loss, mL | 15.20 | 5.20 | 4.40 | 3.60 | 2.50 |

| 30mins Fluid Loss, mL | 6.20 | 5.40 | 4.80 | 4.10 | 2.30 |

| Apparent Viscosity, cP | 6.52 | 7.21 | 8.06 | 8.90 | 10.46 |

| Plastic Viscosity, cP | 5.27 | 5.62 | 6.03 | 6.46 | 7.22 |

| Yield Point, lb/100ft2 | 2.49 | 3.19 | 4.05 | 4.93 | 6.49 |

More so, Table 3.0 shows the results of the filtrate volume of Afaha Oku mud upon the introduction of carboxyl methylcellulose. Thus, from Table 3.0, the filtrate volume of Afaha Oku mud at 10minutes decreased from the initial value of 205.3mL to 15.2mL (about 93%) at a concentration 8.58g of CMC to 350mL of the local clay mud (Sample A).

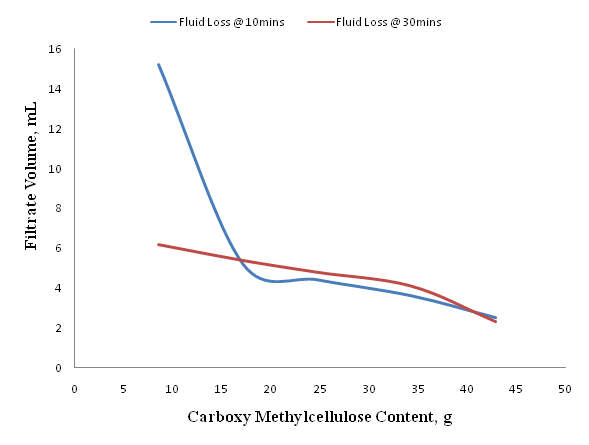

Figure 2.0: Effect of Carboxyl Methylcellulose on the Filtrate Volume of Efiat Offot Mud

Figure 3.0: Effect of Carboxyl Methylcellulose on the Filtrate Volume of Afaha Oku Mud

Hence, a comparison of the fluid loss volume of bentonite at 10 minutes (Table 1.0) with those of the local clay muds (Tables 2.0 and 3.0) indicates that the local clays improved favourably with the addition of carboxyl methylcellulose (CMC). Figures 2.0 and 3.0 depict the effect of carboxyl methylcellulose on the Efiat Offot and Afaha Oku mud respectively.

The figures show that the filtrate volume of local muds decreases with increasing carboxyl methylcellulose content. This then implies that the local mud’s performance improved in terms of fluid loss upon being beneficiated through the addition of carboxyl methylcellulose.

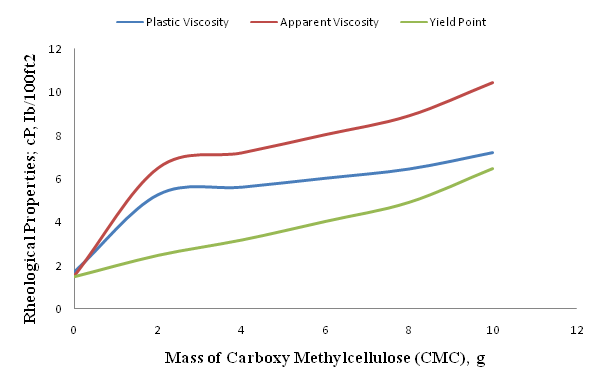

More so, Tables 2.0 and 3.0 also present the increase in the plastic viscosity, apparent viscosity and yield point of the different local clay mud samples with increase in CMC content. From Table 3.0 which presents the result for Afaha Oku mud, the plastic viscosity, apparent viscosity and yield point increased from 5.27cP, 6.52cP and 2.49lb/100ft2 to 7.22cP, 10.46cP and 6.49lb/100ft2 respectively. The plastic viscosity, apparent viscosity and yield point increased about 37%, 60% and 161% respectively.

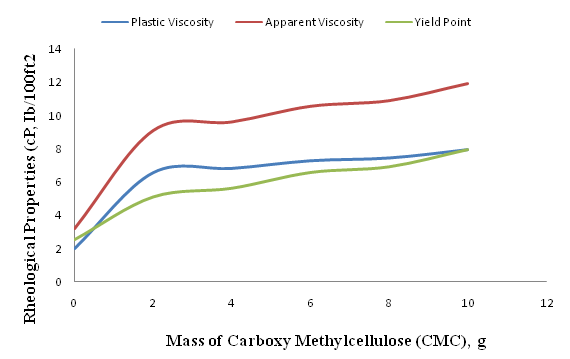

From Table 2.0, the yield point, plastic viscosity and apparent viscosity of the Efiat Offot mud increased from 5.12lb/100ft2, 6.55cP and 9.11cP to 7.97lb/100ft2 (about 56%), 7.22cP (about 10%) and 11.92cP (about 31%) respectively.

Figures 4.0 and 5.0 below depict the effect of CMC content on the plastic viscosity, yield point and apparent viscosity of Afaha Oku and Efiat Offot local mud respectively. Hence, a comparison of the local clays rheological properties (Tables 2.0 and 3.0) with those of bentonite (Table 1.0) indicates that the local clays improved favourably with the addition of carboxyl methylcellulose (CMC).

Figure 4.0: Effect of Carboxyl Methylcellulose on Afaha Oku Mud Plastic Viscosity, Apparent Viscosity and Yield Point

Figure 5.0: Effect of Carboxyl Methylcellulose on Efiat Offot Mud Plastic Viscosity, Apparent Viscosity and Yield Point

References

- Suitability of Using Agbarha Clay for Drilling Mud Formulation in Oil and Gas Industry

http://www.ijesmjournal.com/issues%20PDF%20file/Archive-2015/JUlY-SEPTEMBER-2015/3.pdf - ENHANCING THE PERFORMANCE OF UBAKALA CLAY FOR USE AS DRILLING MUD.

- Formulation of water-based drilling fluid using local materials

- Properties and application of Nigerian bentonite clay deposits for drilling mud formulation: Recent advances and future prospects

- EVALUATION OF THE EFFECTIVENESS OF LOCAL CLAY FROM EBONYI STATE, NIGERIA AS A SUBSTITUTE FOR BENTONITE IN DRILLING FLUIDS

- http://eprints.covenantuniversity.edu.ng/12564/1/1-s2.0-S0169131717301102-main.pdf

Shared on twitter

https://mobile.twitter.com/Iam_LilTom/status/1229342587569549314

Excellent work friend @tomlee, always experimenting and researching on how to improve drilling fluid based on locally used additives.

@tomlee I have a question: Do you have information about the wells drilled in your area, if there are problems with pipe sticking due to a bad formulation of the drilling fluid? If you do not use the right additives you run the risk of drilling with a water based fluid and you can swell the shales causing this sticking in the pipe string

We really do not have cases of differential pipe sticking here.

Excellent friend @tomlee, that's an operational advantage that they don't present that kind of problem. Greetings friend I hope to read more of your articles on drilling fluids very soon

Pleasure will be mine

This post has been voted on by the SteemSTEM curation team and voting trail. It is elligible for support from @curie and @minnowbooster.

If you appreciate the work we are doing, then consider supporting our witness @stem.witness. Additional witness support to the curie witness would be appreciated as well.

For additional information please join us on the SteemSTEM discord and to get to know the rest of the community!

Please consider using the steemstem.io app and/or including @steemstem in the list of beneficiaries of this post. This could yield a stronger support from SteemSTEM.

Thank you