Swarm: Just Another Change Coming In Manufacturing

Technology is going at an amazing rate; it is truly fascinating.

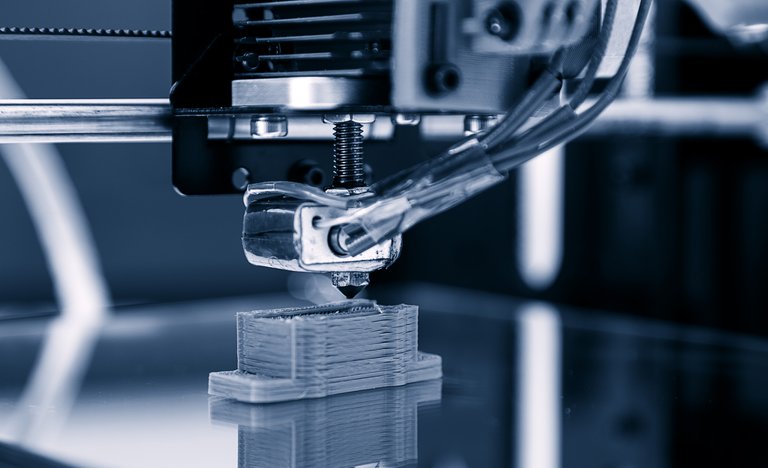

Over the last few weeks, I discussed some of the changes in the manufacturing segment including 3D printing. This was more associated with home building which is moving into the manufacturing realm.

Historically, 3D printing has done well in the automotive and aeronautical industries. These are still two of the leading sectors although it is expanding a great deal.

Computerization and AI is really altering how things are made. Over the course of this decade we will see a major shift in how we produce physical items. This should create a great deal more automation with manufacturing taking place locally. It is a radical shift from the make and ship model we presently use.

One area that we are seeing a great deal of interest is in swarm manufacturing. Taking the idea of how bees operate, swarm manufacturing uses multiple robots to make different products.

Now we are seeing the idea of swarm 3D printing. Here is a video that shows how this operates.

The key here is getting the different pieces all working together. As with other forms of swarm manufacturing, these processes grow as more units are added. There are videos that show dozens of "flying robots" all working together. We can expect the addition of more printers to create more complex structures.

Autonomous systems hold great allure to companies since they can be set up and run without human intervention. With recent events, we see a great deal of appeal with the elimination of humans in the process. As with many technologies, this does not bode well for employment or jobs.

Swarm is said to provide a lot more flexibility and efficiency than traditional manufacturing processes. When we couple this with the benefits provided by 3D printing, less waste, lower cost, and faster manufacturing time, we can see how this could provide exponential payout.

The future of manufacturing is rapidly changing. We saw the shift towards automation over the last 30 years, most notably in the automobile industry. With the ability to print items out from digital scans, we will see a radical change in how products are distributed.

It is far easier to send digital files around the world as compared to physical items. The idea will be to transmit the scan to where it is needed and print the item out locally. This means we should see a reduction of the cost due to the fact that moving raw materials is less expensive than finished goods.

A couple decades ago, the world was altered when the personal computer and printer came into being. What was once produced on printing presses suddenly enabled anyone to create paper documents in their home or office. We will see a similar shift in physical products which can be "printed" out in ones business or home.

Eventually, everyone will have these devices in their home just like we did the last few years with desktop printers.

History is repeating itself, only on a larger scale.

If you found this article informative, please give an upvote and rehive.

gif by @doze

Posted Using LeoFinance

I find it very fascinating what we can create with 3D printing. I can't wait for the possibility of having such a "toy" at home. In a few years it will really be a "basic" item in a home.

Posted Using LeoFinance

The timing is tough but I think it will be more than "a few years" for in home 3D printing. However, we will see localized print on demand within a few years in many parts of the world. That will give people a lot of access to the technology and reduce the costs of production of physical items.

It is all going to come together.

Posted Using LeoFinance

All in good time ... The journey will be long, but fun.

Posted Using LeoFinance

3D home printing is a kind of technology that really impressed me alot and i find it fascinating...@taskmaster4450le

Posted Using LeoFinance