New method for the treatment of acidic industrial wastewater

Image credit: pixabay.com

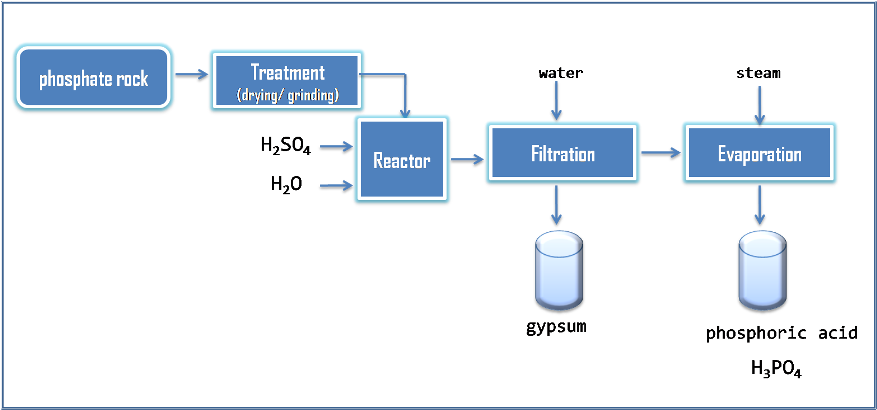

The industrial production of phosphoric acid, in most industrial plants, is carried out by a method called the wet process, a chemical process that involves the attack of phosphate rock with concentrated sulphuric acid in a stirred reactor, the operation proceeds at 70 °C and results in phosphoric acid about 30% in P2O5 and calcium sulphate dihydrate, CaSO4.2H2O, also known as gypsum. The reaction products then pass through a filter that separates the gypsum from the phosphoric acid.

Industrial production of phosphoric acid. Image prepared in Powerpoint.

In the filtration stage, the gypsum is washed with process water to recover as much P2O5 as possible, and then the leachate is collected in settling ponds. The problem with these leachates is that they are strongly acidic, and represent a great environmental risk as these ponds are prone to leakage and flooding.

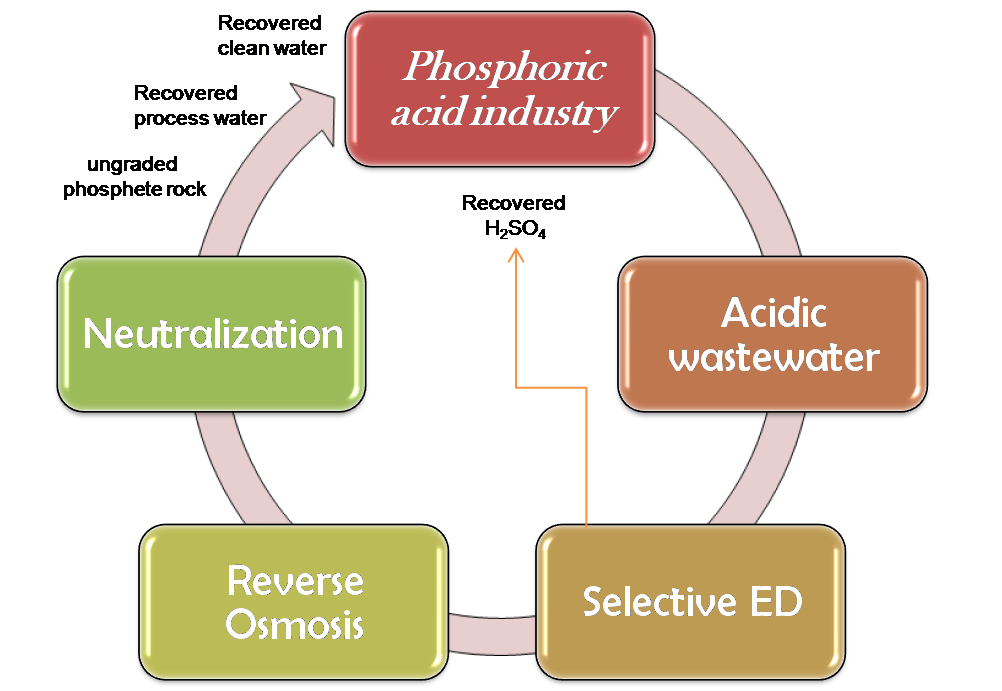

Faced with this environmental liability that is being generated in phosphoric acid production plants, a team of researchers from Ben-Gurion University of the Negev have developed a method to eliminate this environmentally hazardous wastewater, including a circular process that not only produces clean water, but also recovers valuable products.

It is well known that conventional industrial wastewater treatment processes have difficulty removing the acidity, salinity and hardness of wastewater from the chemical industry. This is why the new method developed contemplates three fundamental stages that include selective electrodialysis, reverse osmosis and neutralization, to treat this water from the manufacture of phosphoric acid.

New method for the treatment of acidic industrial wastewater. Image prepared in Powerpoint.

This research team evaluated the method with synthetic wastewater with promising results, electrodialysis yielded high selectivity for Na/Ca at low pH, which allowed the recovery of gypsum-free H2SO4, which in turn prevents scaling in the reverse osmosis stage, successfully recovering clean water (>90%). While a final neutralization stage with phosphate rock allowed the acidity of the concentrate from the reverse osmosis stage to be removed and phosphorus to be recovered at the same time.

In addition to obtaining good quality water and valuable products for the industry, the method has a low electrical energy requirement, which makes this method a sustainable and economically feasible solution for the treatment of hazardous acidic water from this type of industry.

Well friends, let's hope that the industry is encouraged to evaluate the potential applicability of this method. Thanks for stopping by to read.

References

- Lior Monat¨, Wei Zhang, Alice Jarošíková, et al.(2022). Circular Process for Phosphoric Acid Plant Wastewater Facilitated by Selective Electrodialysis; ACS Sustainable Chem. Eng.

- Monticelli, S y Dautant R. Evaluación de alternativas de recuperación del fósforo aprovechable en los lixiviados de fosfoyeso de Tripoliven C.A

Hopefully this new method will solve most of the problems!

!1UP

You have received a 1UP from @gwajnberg!

@stem-curator

And they will bring !PIZZA 🍕.

Learn more about our delegation service to earn daily rewards. Join the Cartel on Discord.

Thanks for your contribution to the STEMsocial community. Feel free to join us on discord to get to know the rest of us!

Please consider delegating to the @stemsocial account (85% of the curation rewards are returned).

You may also include @stemsocial as a beneficiary of the rewards of this post to get a stronger support.