Sometimes Things Just Go Wrong

Hello Everyone,

I've been working tirelessly for the past few days to bring some kind of epic 3D printing content to the Hive blockchain.

Unfortunately I have not reached that point yet, and have gone somewhat in reverse.

I had to change slicers, from SuperSlicer (due to what I thought was Superslicer profile errors, not sure if I was right about that.) to Cura, then everything went from bad to worse.

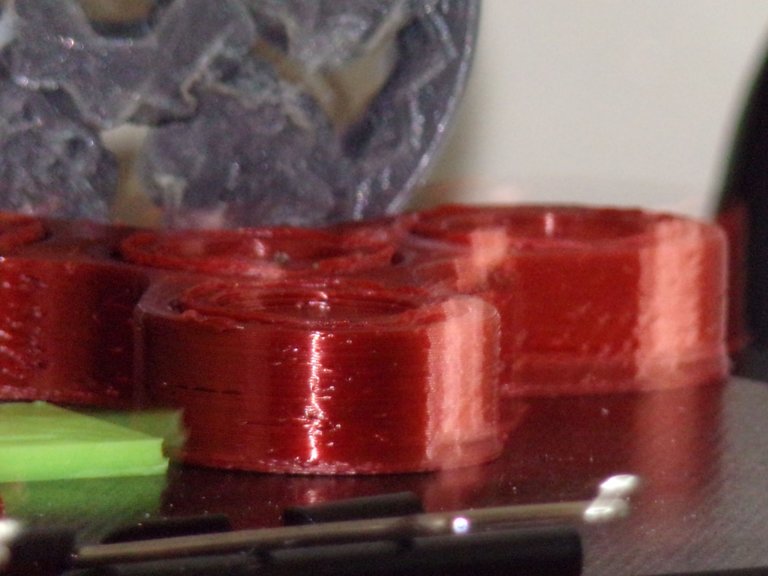

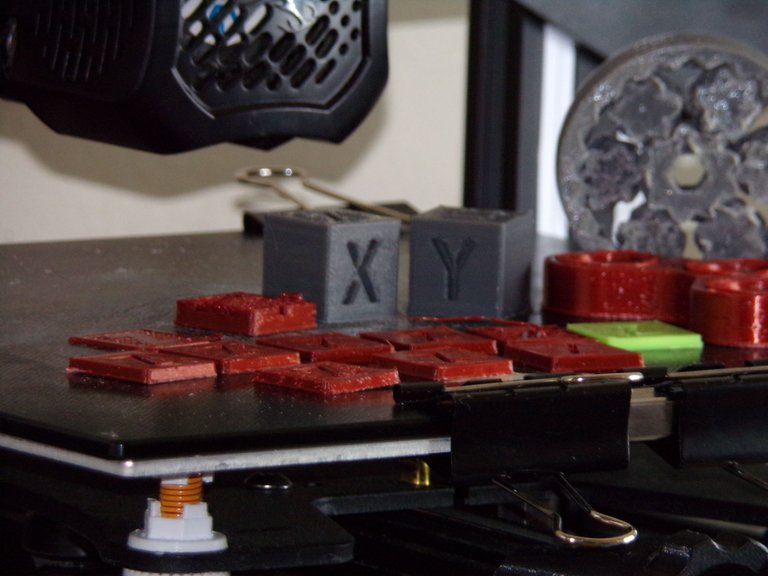

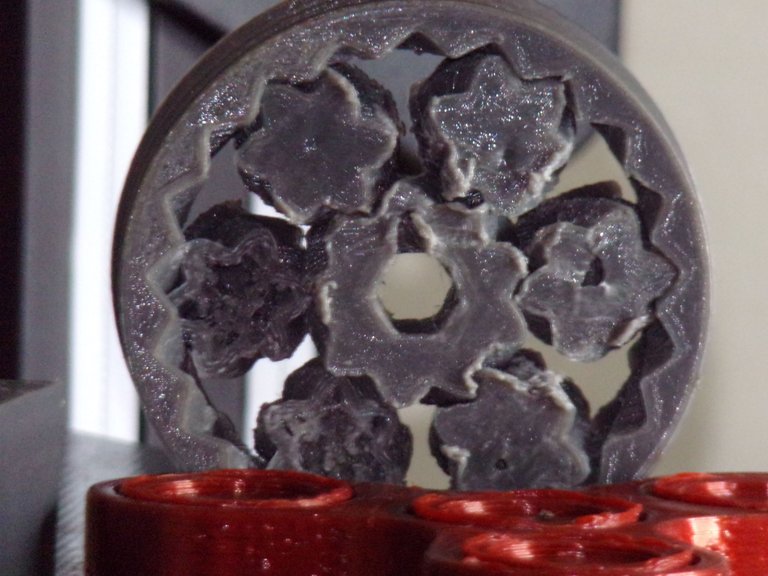

I've been printing Test Cubes and print in place gears, and even a print in place fidget spinner.

And although fidget spinners and gears are cool, I didn't print them for fun, and the dreaded cube has seen more print time on my Ender 3 V2 than any other print by far.

Forget about counting sheep for sleep, (plenty of those around) I count cubes these days.

I was working on a wall hook design (still am) but had to put it on hold due to these crazy under extrusion problems.

I have good first layer squish, but printing at 80% flow rate, and the results are visible, missing layers and overall under extrusion.

Even with 80% flow, I cannot print "print in place" parts without the parts fusing together from the compression.

My main issue is extrusion and shell thickness I think.

The layering is quite nice, I'm really pleased with it, just having issues with the under extrusion and parts fusing.

I was able to get the gears spinning with brute force applied with needle nose plyers, but the gears started breaking in half because of the under extrusion.

This terrible defect tells me exactly what I need to know, and is why I'm able to diagnose the extrusion with no doubts.

What I am having trouble with is how I am going to increase the extrusion with decreasing wall flow while avoiding elephanting, which invariably will cause the fusing, what a conundrum.

I have my work cut out for me, and hopefully I will have some amazing prints to show you all in a day or two.

Any ideas, thoughts, opinions are welcome, if I am missing something that you see, please let me know!

That's it for today, thanks for stopping by and have a wonderful day! ~~@print3dpro

I know nothing much about 3D printing, but the lines and gaps suggest you're in some trouble. I'm not exactly sure how to overcome that, perhaps cooling? Perhaps the material? Perhaps the heat? I have no idea and do not want to give you even more trouble trying to answer me.

Hello, thank you for the feedback @davidke20,

In this case, heat and cooling is not the issue (although too much or too little heat will cause similar problems!)

Best way to describe it is like this.

That roll of filament, has to be fed to the nozzle with a little motor.. if the motor doesn't feed it fast enough , or feeds it too slow, you have flow problems, extrusion is the technical term.

You can also adjust that flow specific to inside structure (infill). wall (shell) thickness, as well as layer height, and first layer height.

There are so many settings to fiddle around with in this area.

Have a great night, and thanks again for the great feedback and support!

I just found tiny white flakes affecting the gears on my 3D printer. I can't do a chemical analysis to confirm but I am 99.9999999% certain that's PLA debris from the brittle sample filament that built up over time.

By the way I don't know if you've scrolled through some of my past blog posts but I made a few about 3D printing before I got my 3D printer. Probably the most "epic" one was a post about a YouTube video in which a woman was walking around with a functioning delta printer on her back.

https://peakd.com/hive-163521/@holovision/portable-3d-printing

Hey man, thanks for the resource.

I did scroll through maybe a month worth of your posts but I think I missed this one.

I saw you were playing around with Tinkercad too, that's a really nice browser program that I'm currently using. I downloaded Fusion 360, but admittedly it is intimidating when I open it, and I quick close and open tinker.. I have to get over this fear of learning Fusion.

I can confirm that not only are you correct, also this problem is non stop on an almost daily basis.

My printer is pretty gunked up right now and I'm pretty sick of cleaning it. I bought an industrial air blower just for that purpose.

I have an aversion to cleaning stuff when I'm busy.

Right now I am keeping my 3D hobby as cheap as I can. Around the time the global pandemic started I got certified as an assistive technology specialist. Hopefully in a few months when everything is reopened I can find work in that field. I'll be earning some money to buy better equipment and use my newly developed 3D printing skills to research and develop some assistive technology ideas I have.

The fact that my country's tax laws have certain benefits for inventors and I can probably claim my next 3D printer purchase as a tax deduction is just a happy coincidence.😎

I wish you the best with this endeavor and believe there is certainly a market for assistive tech in the future. It makes sense that it would be a growing industry.

I bought my 3D printer with crypto, as well as every part and accessory needed, and then got wrecked and lets just say the market has not been kind to me.

I was fortunate to get everything I needed for the printer before getting wrecked, but now I'm pretty much in the same boat and buying even rolls of filament is not going to be easy for me.

I didn't report my crypto pennies and don't care to. The little bit I turned into cash didn't even add up to tax brackets, and the whole institutional forceful demand for us to report is pretty vile and disgusting to me as a crypto enthusiast who believes it should have helped us detach from the broken monetary system we are enslaved under, but that's another topic entirely.

I would like a flat tax. There's a fan theory I like that states The Joker would rather go against Batman than the IRS because he only commits crimes in which he knows he can claim insanity as an affirmative defense.

Congratulations @print3dpro! You have completed the following achievement on the Hive blockchain and have been rewarded with new badge(s) :

Your next payout target is 50 HP.

The unit is Hive Power equivalent because your rewards can be split into HP and HBD

You can view your badges on your board and compare yourself to others in the Ranking

If you no longer want to receive notifications, reply to this comment with the word

STOPCheck out the last post from @hivebuzz:

Support the HiveBuzz project. Vote for our proposal!

Pushing for exponential! Thank you!

You're welcome @print3dpro, well done 😊👍

This sentence is rocket science to me:

I hope you'll be able to convince the printer to do what you want.

@tipu curate

Upvoted 👌 (Mana: 0/22) Liquid rewards.

I barely comprehend it myself! :P

Thanks a bunch for stopping by and for the support.

I actually did get it worked out to acceptable prints for the time being, by simply running stock settings in Cura Ultimaker. (and deleting my user presets)

In this case I think it's operator error causing malfunctions :)

That's good to hear, in a way :)

It's always reassuring to know that hardware and material. are OK.

Interesting prints, I've never known how these are made...

What materials are used in making these?

And what do you do with them if I may ask? :)

Hello, thank you for the comment and question.

Currently I use PLA (polylactic acid), a biodegradable substance.

I try not to waste much because 1000 gram rolls average around 20 USD per roll and can be expensed pretty quickly with regular printing.

The local trash facilities will process it because it's environment friendly.

For larger failed prints , I save them in a bin for a recycle process I am planning for the future.

I print all kinds of things, currently gardening tools and supplies are probably top of the list for me, and also tool fixtures and electronics casings :)