Retraction, Pressure Advance, and Big Cable Chains

Hello Everyone,

A lot has been going on with the Ender 3 V2 since Troubleshooting a Layering Problem that occurred after installing a hot end mod.

Not only was the layering problematic, but the corners on prints were blobby, seemingly over extruded in some areas, seemingly under extruded in some areas, and overall it just looked like the machine was starting to develop serious mechanical issues.

My first thought was to adjust retraction, which @apshamilton mentioned, in the comment section of my previous post.

But I had not considered firmware retraction as he mentioned, and this helped expand my thinking process outside of the box I was stuck in.

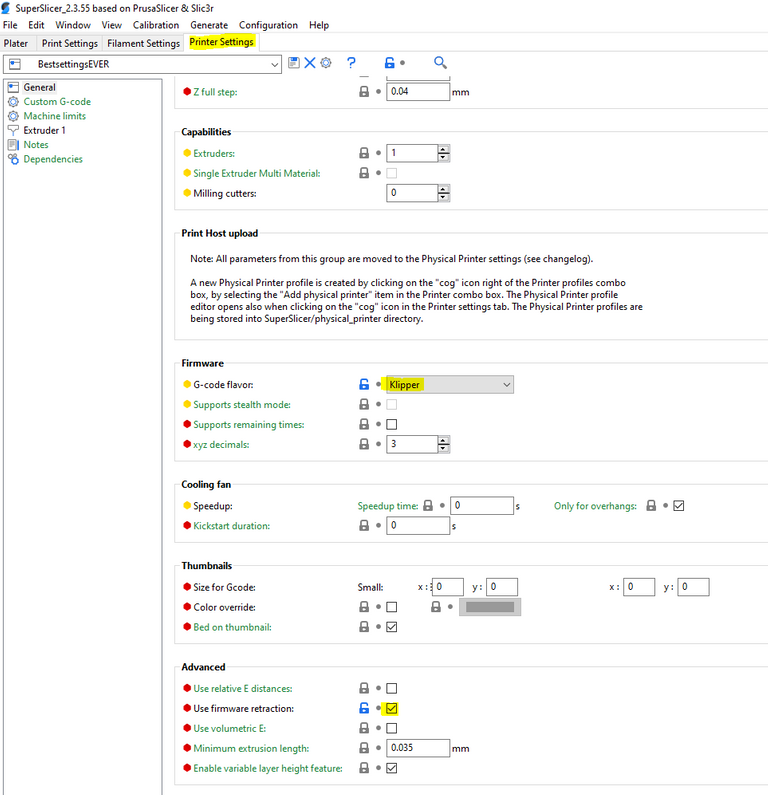

I had been utilizing SuperSlicer's built in retraction settings.

Light bulbs started going off in my mind..

"Could firmware retraction be on and causing error with slicer retraction? If not, would the printer benefit from enabling firmware retraction and disabling slicer retraction?"

I immediately started tackling this, and what I discovered was no retraction parameters in the Klipper printer configuration file.

After this discovery, I learned that Superslicer makes it easy to enable firmware retraction, but that I would also need to find the correct parameters to input into the config.

This link contains a configuration which works perfectly with my printer, and I really like the documentation added as well.

https://github.com/Sprk-nl/3D-printing/blob/master/Klipper/printer.cfg

SuperSlicer

There was a noticeable difference right away but not much, the corners still looked pretty blobby. Through researching retraction, I stumbled onto some documentation for pressure advance.

This was something I had done previously with a prior Klipper config but forgot all about it!

Nero 3dp Youtube

https://github.com/KevinOConnor/klipper/blob/master/docs/Pressure_Advance.md

After a proper pressure advance tuning, prints are definitely looking better, but I'm afraid there are still lines that look like missing layers showing up.

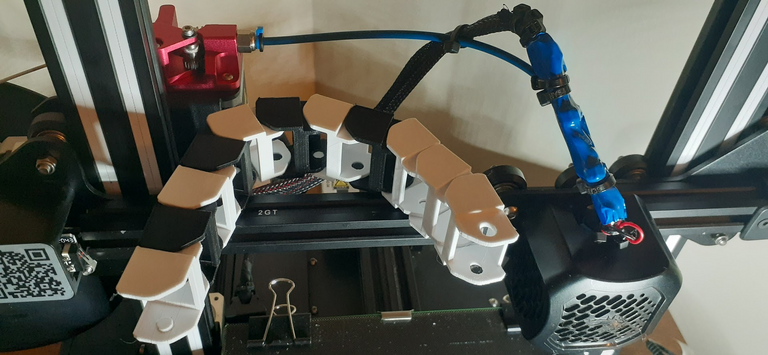

Print-In-Place (PIP) Large Cable Chain Assorted Lenghts (1-9 links)

by TTB_Studios March 20, 2016

I have little doubt at this point that what we are viewing is a mechanical issue.

My next step is to disassemble the printer 100% and deep clean everything, while also replacing some parts. The roller wheels might need replacing if there are any gouges or deviations. I am relatively certain without taking it apart that I am going to find an issue.

I also have a fraying belt on the bed plate, not good at all, and it's fraying due to a poorly printed tensioner fix.

There are all kinds of problems going on here..

Part of me wants to wait until I have the new parts to commence the deep clean, but I probably won't wait.

I have a big addiction to 3D printing and like to have this thing running every waking hour, so I'm running prints slowly to preserve the belt, and am still able to print usable prints currently.

The chain belt I'm working on has some obvious lines, but I've already used so much filament on it that I am just going to finish it and use it.

Also planning to finish the black/white checkered look with a custom appeal, coming in the future :D

Here is a better look at this cable chain that I will have done probably today.

Print-In-Place (PIP) Large Cable Chain Assorted Lenghts (1-9 links)

by TTB_Studios March 20, 2016

The viewer might notice the stock hot end fixture reinstalled. I opted to re-install this as step 1 in the troubleshooting, because it was immediately after installing the mod that all of these problems started popping up.

I don't see the urgency in putting the mod back on at this current time, because machine maintenance is still ongoing.

I'm going to try to make a gif or video of the cable chain once it's connected to the hot end and share it on the blog, These things are super cool looking in my opinion.

What should I print next?

I'm planning to get some hardwood panels and make wall shelving units, and some form of a coat hanger.

These will be good projects to practice designing with due to simplicity.

I've heard great things about Fusion 360 and have it downloaded and ready to go.

My plan is to delve into design training real hard once I have this printer working proper, hopefully that won't take much longer, as I've been in a non stop troubleshooting process for months now, but hey , that's part of the territory with 3D printing, and it's rather enjoyable for me.

I'll leave it there for now.

Thanks everyone for the amazing support/engagement/and just kind words in general, it's much appreciated and gives me motivation to keep learning and sharing this experience here.

Have a great day! ~~@print3dpro

Congratulations @print3dpro! You have completed the following achievement on the Hive blockchain and have been rewarded with new badge(s) :

Your next payout target is 250 HP.

The unit is Hive Power equivalent because your rewards can be split into HP and HBD

You can view your badges on your board and compare yourself to others in the Ranking

If you no longer want to receive notifications, reply to this comment with the word

STOPCheck out the last post from @hivebuzz:

I'm glad my suggestion helped. Klipper has some really fancy features like pressure advance and clever retractions.

But you need to take the time to set them up right.

I'm not surprised that there might be some interference as most slicers are not expecting Klipper firmware.

Klipper is pretty amazing, it reduces the load on the Ender's main board substantially.

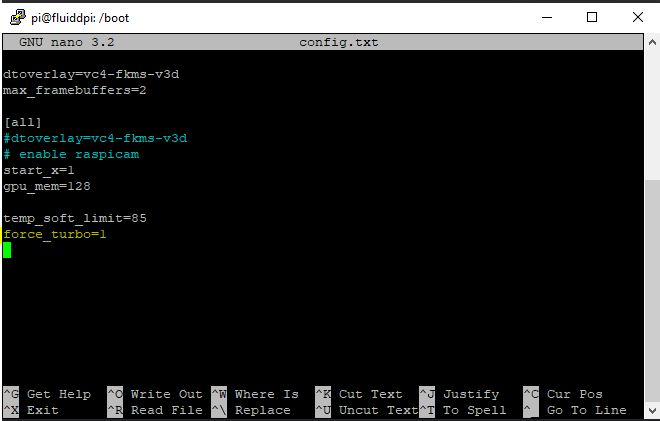

The Pi 3B+ utilizes a varying voltage for ARM to protect from overheating, to solve this under and overvoltage error:

I should probably be monitoring temps instead of blindly trusting that the PI won't overheat :P

This isn't necessary on newer Raspberry Pi's.

I disassembled the printer 100% yesterday and couldn't find any mechanical issues, but afterwards I made a huge discovery in SuperSlicer.

EDIT/Correction: The variable layer height was checked, disabling this was highly effective in smoothing the deviations.

https://www.thingiverse.com/thing:1960183

0.12 mm layer height.

There's still some improvement to be made, but currently the Ender will produce acceptable prints after tackling some of these issues.

Totally, Cura slicing can be unpredictable with Klipper, but is my preferred slicer for spiral vase mode, as it seems to work a heck of a lot better than Prusa/Super Slicer for vase mode, at least with my current configuration.

Your content has been voted as a part of Encouragement program. Keep up the good work!

Use Ecency daily to boost your growth on platform!

Support Ecency

Vote for Proposal

Delegate HP and earn more

Thanks @ecency, much appreciated!