How to mill lumber post 3

Click here for the 2nd post

This is the third part of milling wood. We now have some wood that is cut into planks or beams and it's planed.

I made the beam above they are a bit bigger than usual roughly 200x15x20cm. This will be a couple of the pillars for a double door garage with a hobby area.

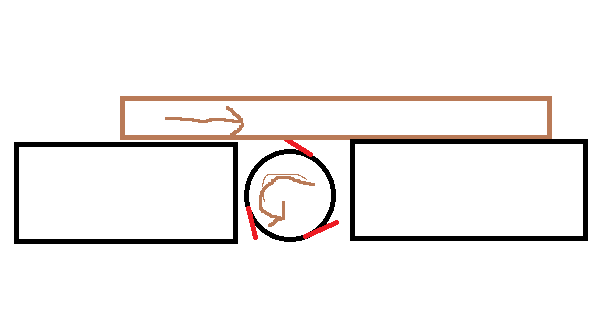

What I today wanted to discuss is the surface of the wood after planing. It often looks like the picture below:

The first problem is the wavy horizontal pattern this is very common. The reason for this is that the planer blades are spinning in a circle taking each a bite out in a circular motion. The edge of the knife moves in a similar way as a dolphin that jumps out of the water.

How to fix this?

There are multiple options the cheapest and most obvious method is sanding the surfacing (what I do) after planing or using a scraper.

The second cheap option is to adjust the planer that it cuts very thin 1mm instead of 2/3mm. This makes it a slow process for building wood, but a good option for quality furniture wood.

The third cheap option is to accept the result, a small wavy pattern in the wood is no problem if you build a garage or want a rougher look.

Expensive options are increasing the amount of blades like a helical cutter this is a roller that has 50 to a 100 blades instead of only 3 blades. This can easily cost 500+ euro's just for the upgrade.

Big drumsanders tables this can cost a couple of thousand euro's, but you will safe yourself countless of hours of sanding!

How I spend my morning today

I like this smallish sander it doesn't vibrate in my hand and it goes quick with very low grit sander paper. In my case grit #32. Woodworking grits go from very rough 24 grit up to a 800 grit. Personally I don't see any difference above grit 400 so I don't spend my time on sanding it smoother than that.

Posted with STEMGeeks

Congratulations @gogreenbuddy! You have completed the following achievement on the Hive blockchain and have been rewarded with new badge(s) :

You can view your badges on your board and compare yourself to others in the Ranking

If you no longer want to receive notifications, reply to this comment with the word

STOPDo not miss the last post from @hivebuzz:

Congratulations @gogreenbuddy! You received a personal badge!

Wait until the end of Power Up Day to find out the size of your Power-Bee.

May the Hive Power be with you!

You can view your badges on your board and compare yourself to others in the Ranking

Do not miss the last post from @hivebuzz:

Congratulations @gogreenbuddy! You received a personal badge!

See you at the next Power Up day to see if you will repeat this feat.

May the Hive Power be with you!

You can view your badges on your board and compare yourself to others in the Ranking

Do not miss the last post from @hivebuzz: