My "First" 3D Printer Purchase & Install Experience

The first time I was considering to buy a 3D printer was when I heard they were getting more reliable and affordable from a colleague back at work.

I always wanted to 3D print objects I have designed, toys for my kids, or print some parts around home that can use a fix even. The problem is... no matter how many YouTube videos I watched, I don't think its the same as when you are there looking at it in action in front of your eyes.

And that is correct.

You cannot assume the build quality and print quality is good by an Amazon.com jpeg image. 3D printers to me as a designer are like musical instruments to a musician. If I am a musician and I need to buy a violin... would you just look at a photo on Amazon/eBay and decide what is best for you? No! Of course not. :)

So I headed to Micro Center when I was living in Georgia and really took it all in and be open minded about brands and price point. So off I went in!!~

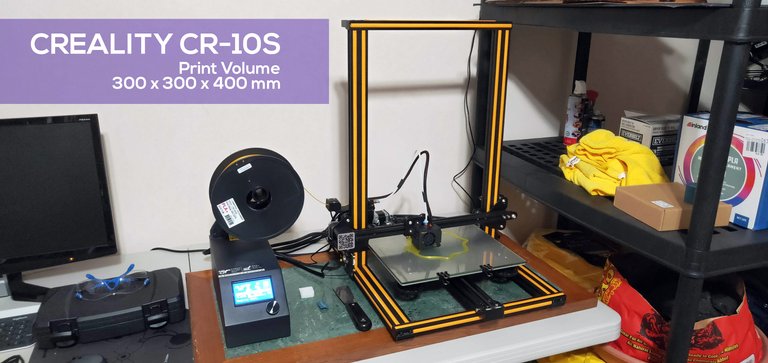

I decided to go with the Creality CR-10S.

https://www.creality.com/

I just looked up to see if my model was there however I think its replaced with the much better CR-10 Smart. The underlying basic principles should be the same. This is the newer model below and I think mine is now discontinued.

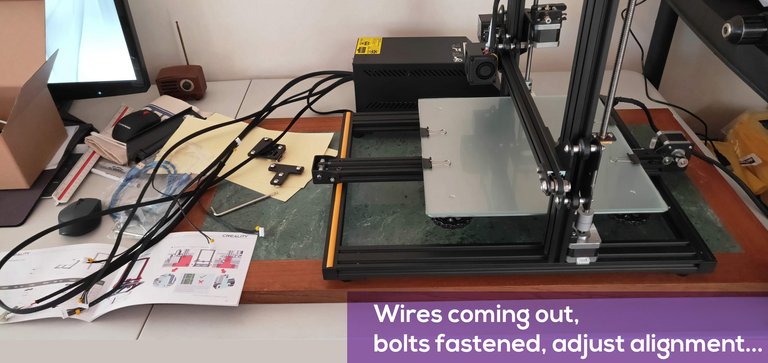

The first time I opened the box and took the printer out to be honest it was scary. Because I had no idea what is what... it was so alien to me at first I didn't know how much I needed to tighten or anything what so ever.

I would like to comment. When I bought this one (2 years ago) 3D printing was about to get some traction before the Corona Virus hit worldwide. But maybe its still kind of at a development stage? This is not something you see on the ads of 3D printers... its NOT plug and play. So don't expect it to be like HP ink jet printers, where you just place in the ink carriage and off you print. I do know that day will come some day... but not now.

I was a little worried when I first saw this actually.

I always go through the manual once before I begin... mental install first. :)

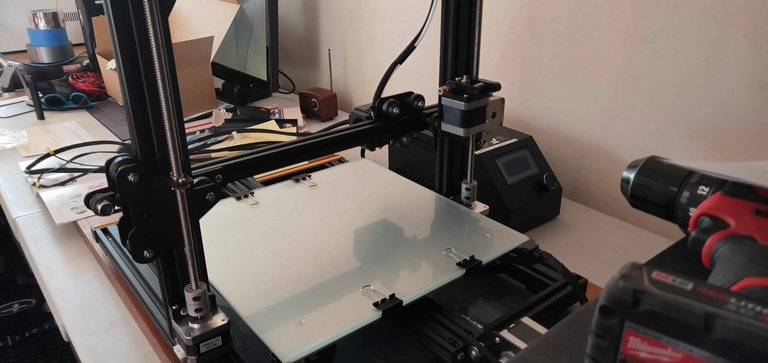

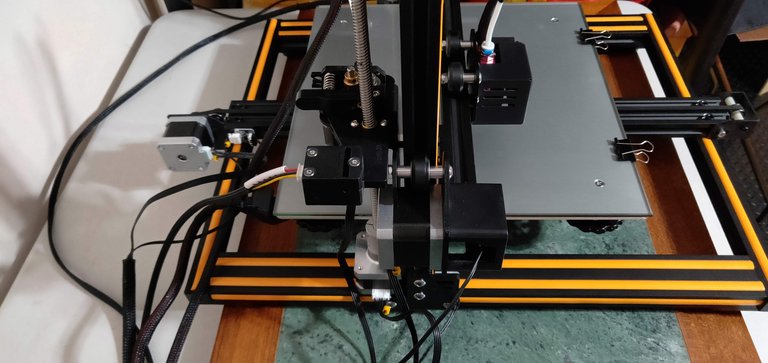

Slowly but surely its starting to look like a the Creality CR-10S!

I didn't even know what this was at first...

Now starting to connect the wires one by one through the pins.

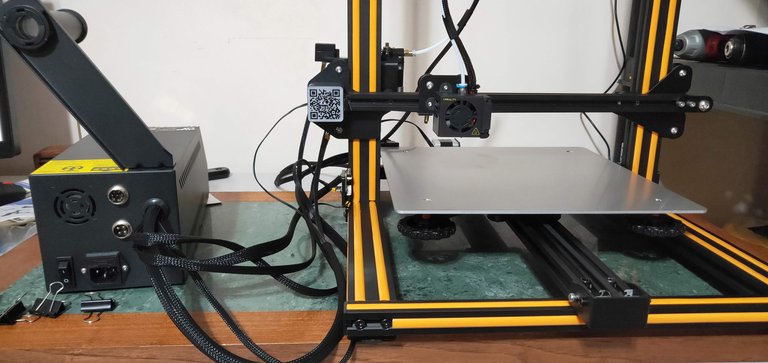

TADA!!! Finally built the damn thing and ran a test run Benchy on it.

and it worked great!~~ The very first time when building something new it does get intimidating for sure. However this is why I went with a lower budget printer at first so I can familiarize myself with it.

Since FDM Printers like this one all work on the same set of foundations and other brands have small tweaks here some minor features there. Overall basic functions are the same.

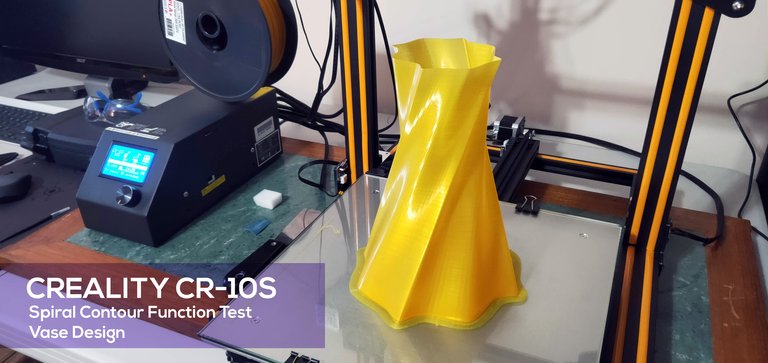

For a budget printer its actually very good in tolerance and models are pretty detailed even with normal 0.2mm height. I was very satisfied with the test quality and started to print a bit more complex shapes to see if the printer can handle stability when printed high.

I decided to go with a vase design and I learned on the 3D Printing software its called a "spiral outer contour" where it will print the model outer shell with the thickness of the print nozzle. So basically egg shell thin... Did it work?

Well.... Amazingly well. :)

For what it is... it exceeded my expectations for sure.

There is no warping or drooping of material to the side... just clean.

At the time I knew I was going to have so much fun printing other things and various materials. I felt like a kid again!!!!

I realized that 3D printers the larger they are the more silent they are too. One thing that was cool at first but started to get annoying fast was the sound of the servo motors winding and the internal fan noise is pretty loud. I recommend do not put this next to where you sleep. I did in the beginning because it was so cool however the noise later was too loud for me to sleep.

As all 3D printers they will require some maintenance because there are a lot of moving parts and temperatures of nozzles go as high as 240 C. Wear and tear of the belts later will create issues in so many factors but I will explain that for another day.

The story goes... I have ended up buying 2 more Large 3D printers (Creality CR-10 MAX) and also 2 Dental Grade Resin Printers later using it for both my work and hobby alike. So stay tuned for some more experiences from a complete NOOB to now I can say I am pretty confident 3D Printer Specialist?

I would like to let people know that they can go from nothing to learning something and becoming pro. If I can do it.. then anyone can do it.

Thanks for viewing my post and swinging by today!

Hope you guys will have a wonderful day/night.

Set Da Tone!!! :)

Awesome.

I would love to have a 3D printer too. Just need a list of what to print and to improve my 3D modeling skills first. 😊

!1UP

Its ok to take your time step by step. Because I think 3D printers will become more better and reliable while the cost becomes cheaper and cheaper. Mine are already discontinued I think. No need to rush~ and thanks for the 1UP !!!! Truly appreciate it!!!

You have received a 1UP from @thecuriousfool!

@stem-curator

And they will bring !PIZZA 🍕.

Learn more about our delegation service to earn daily rewards. Join the Cartel on Discord.

Sweeet the cartel is coming and some pizza??? 😍😍😂😍😍

PIZZA Holders sent $PIZZA tips in this post's comments:

@curation-cartel(1/20) tipped @whangster79 (x1)

You can now send $PIZZA tips in Discord via tip.cc!

I was interested in 3d printers for a while and you already know that dude. Looks like you're a master now. I wonder if you started printing toys for your kids?

Ahhhh yes @incublus you are good at predicting the future my friend. Toys is just the start~ I am going through my photo album to pick out some of the stuff I printed that were pretty cool. I just need to know where in the world they are.... I have like 800 billion photo files scattered around and trying to organize them... this is like falling into a rabbit hole!!! Stay tuned bro. Thanks!!

I'm waiting for your next post! I wonder about what I'm going to see.

😆don't know what's the usage of 3D printer yet, but it looks very nice👍

I am glad you asked~~~ Your not the only one and dont worry cause through my posts you will become a master. A whole posts of what they do and what they can be for is coming its way. :)

But to give a quick answer to your question, a 3D printer can print out objects much faster and cheaper than when you have to ask a factory... its great for checking if your design for example can actually work by printing them and checking before you go to production. DERPPPPP... maybe my posts will explain better after I create it. :)

👍👍 okay I will read it carefully, it seems to be related to your work😄

yea sometimes when I talk work stuff I forget that I am using engrish.... 😂😂 It get many people confused too.

I will explain it in photos in a different blog... its more clear. hahaha

👍👍okay

Amazing!! It's kind of a human nature when we see tutorial on YouTube etc it's seems to easy but actually trying for real is always a new experience.

And yea no one would buy seeing jpeg on Amazon ~ it's always good to pick up by own from market.

Happy for you that you're satisfied with it and enjoying making module on it!

Haha I never tried before so don't know how it feels like but enjoyed reading your experience.

Have a great day ahead bruh!

I think these machines are like musical instruments. People will always see and enjoy the music performance however they never see the long practices they go through. 3D printing is the same... it looks easy when you see it.... but it needs practice... a lot of it too. However once mastered.... it becomes second nature. :) Sometimes I love it and sometime I yell at my machines when things go wrong. hahahaha~

Picking up from the market~~ is always the best way.... same goes with picking fruits and vegetables at the market.... if you can see it, touch it... you will pick the best one when you buy.

Thanks and have an awesome day too!!!

Yea perfectly said each and everything!! Loved the example of music performance and practices!

Haha, yelling on machines literally sounds like me when my internet stop working.

Indeed, very well said!

Thanks mate. 💕 Much Love.

Many 3D printer tutorials are available on YouTube, they look easy-peasy to watch. It may seem like a matter of minutes but yes, you hit the nail on the head, we don't know the truth until things happen before our eyes.

So you have three different 3D printers, I can easily say that you have become a pro player.💕

You rightly said that if you can do it, everyone can do it, but here it is a matter of passion also, if someone wants to learn this with passion and excitement, he will learn it soon.

You have given a good advice @whangster79 that it should not be placed in sleeping areas. If I ever go through this experience, I will definitely keep this in mind.

Wow you made a great one. The color is very attractive. GOAT💕

Hey @faiza34 ~

I will create another blog post that discusses about failed prints and more than half of the time it fails when its a new design.

Prints failing is very common in the world of 3D printing and the failure can be so many different factors.

Its not just human error... even the moisture in the air can make a print successful and one not.

However, its from the failures I learn the most on why, what, how, when.... and the next time is always better.

Thanks for your comment!!~~ Always happy to hear them.

Indeed

Your plus point is "You must have failed but you didn't give up".

Man learns from his mistakes. Infect learns from nothing else as much as he learns from his own failure.

I hope I learned something in life from all this failing... but to tell you the truth so many times I have no idea what the hell I am doing. CLUELESS!!!! 😂😂😂

I think you explore a "Digital World" haha😅

The Matrix has me~ :)

So I count 5 printers in total!! What are you up to? Running a factory ? 😉

Hey @livinguktaiwan ~~

I can explain its so stupid but makes so much sense.

A design 3D print usually takes about 8-12 hours to print a part.... and during lets say it was printing 5 hours and failed.... then I need to start the thing alllll over again.

Now~ with 2 printers with different print settings of same part... your failure rate is now cut in half. 50%!!! is a lot...

With clients removing margin for error is pretty important to customer satisfaction I think..... Being on time is what makes or breaks deals.

Also same goes with if you need to print multiple parts at the same time then it finishes the task twice as fast~~

so having two is a lot much better than just one machine.

and with Multiple printers~~~ this can exponentially cut time in so many ways... productivity skyrockets.

This all works when your have projects that are working through~~

IF no projects~~ they are just metal sculptures. Sad metal sculptures.... :)

I had a feeling someone would ask~~~ glad it was you.

Cheers!

To be fair, the metal sculptures look pretty cool!!

I had no idea it takes so long to print something, and you say they may fail. What happens to the failed product, does it go in the bin or can you recycle the material? I hear the "whatever you call it bits to print" are quite expensive.

A failed print is basically when the finished result does not meet what look like on the file. Human error, surface area, temperature, humidity... they all have a say in it.

What do we do with them is go into the bin... some are trying to figure out to recycle them but its not as easy as like composting at home.

Most of the material used for these types are PLA material, and I did hear that they are made from sugar cane.

Cost of 3D printing is all calculated simply with time and material. Its the time that kills the attraction~ although companies are working to improve this. And its expensive probably because of time... :)

I can relate the feeling you had here with this 3D printer..at first it would look all scattered and confused but if you follow the manual you will get the puzzles hehe 😂 😂

And YouTubers need to learn how to put out accurate procedures on how those things works because seeing it in the physical contact is different from those uploaded content.. It sucks like hell...am liking the 3D stuff though...

Although I have little idea on how it works but from the comment section am learning 🙃

For content creators for YouTube I can understand that after all they are creating an advertisement.

Over here I believe its different we are creating infotainment. Sharing information as raw as it can be.

Honesty always pays off in the long run.

Thanks for the comment!~

I like that though...infotainment...😆

Sounds much valid.

My utmost pleasure.

Congratulations @whangster79! You have completed the following achievement on the Hive blockchain and have been rewarded with new badge(s):

Your next target is to reach 800 replies.

You can view your badges on your board and compare yourself to others in the Ranking

If you no longer want to receive notifications, reply to this comment with the word

STOPSupport the HiveBuzz project. Vote for our proposal!

La verdad que empezaste con una muy buena maquina, yo tengo una CR10-V3 la antecesora de la que compraste, vas a poder imprimir cosas gigantescas

¡Hola, es un placer conocer a un compañero que tiene el mismo pasatiempo! El tamaño grande es mucho mejor en el cr-10 max porque para los cr-10, cuanto más alto imprime, es menos estable. Sin embargo, en comparación con v3, sí, tiene razón. Mejoraron el tamaño y todo lo demás es igual.

!discovery 30

This post was shared and voted inside the discord by the curators team of discovery-it

Join our community! hive-193212

Discovery-it is also a Witness, vote for us here

Delegate to us for passive income. Check our 80% fee-back Program

Yay! 🤗

Your content has been boosted with Ecency Points, by @whangster79.

Use Ecency daily to boost your growth on platform!

Support Ecency

Vote for new Proposal

Delegate HP and earn more