Working on Two Projects Currently

Hello Everyone,

It's been almost a week since my last post so I wanted to make an update post to let all of you know what I am currently working on.

I'm working on a design for the Ender 3 V2 4.2.2 motherboard, and currently am about 50% done.

But this project has taken a bit of a backseat while I work on something cooler.

So let's talk about that first.

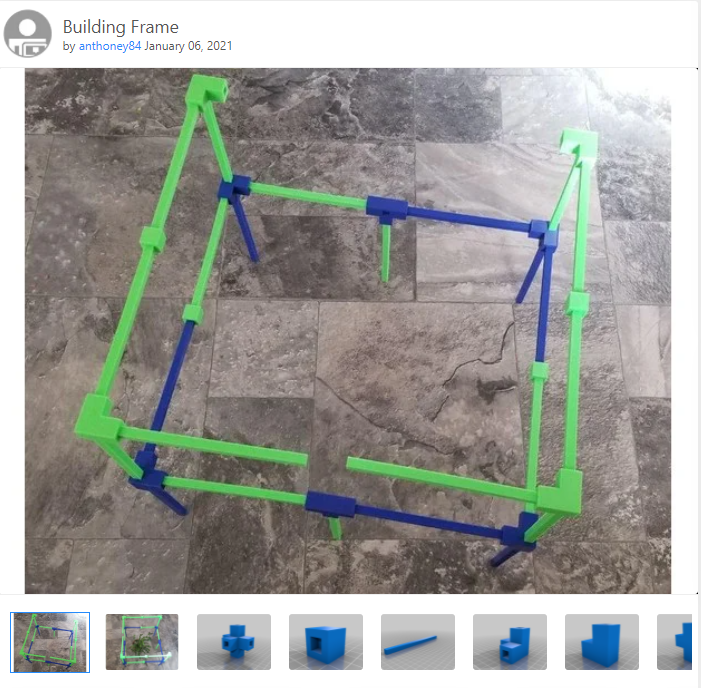

I'm building a indoor greenhouse/tent like enclosure for seedling plants.

I found this super cool building frame on Thingiverse and I see so much potential for projects, and even have some ideas forming for creation of some DIY kits with these specific building parts since I can scale them smaller or bigger to adapt to different applications.

Building Frame

by anthoney84 January 06, 2021

Building Frame byanthoney84is licensed under theCreative Commons - Attribution license.

Building Frame

by anthoney84 January 06, 2021

Building Frame byanthoney84is licensed under theCreative Commons - Attributionlicense.

It took quite a bit of searching on Thingiverse to find this, about 3 days of searching.

Apparently construction frames with all parts 3D printed are a little difficult to find, (or I am using inefficient keywords :D) but anthoney84 pulled through with this beautiful frame for the community.

I imagine designing something like this wouldn't be too difficult, and with a limited array of them available, I am considering designing some different styles of this (remixes) in the future.

For now I am just going to use this one :)

This is currently a work in progress for me, and will probably take at least another day to complete.

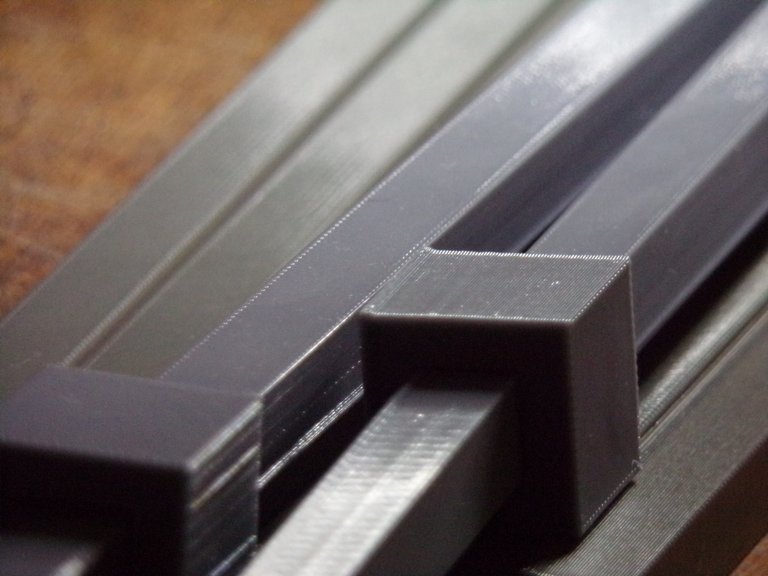

Printed at 0.28 mm layer height, the 200 mm "pipes" (which are laden with 30% hilbert curve infill) have been printing for about 18 hours total, utilizing TECBEARS PLA grey and black filament.

(The connected pieces on top were printed with Esun grey, last on a roll I had, hence the small color deviance.)

I may introduce more colors and different filaments into the structure because I'm starting to run low on filament and need to get some more.

There is absolutely nothing to complain about with these printed parts. The connecting pieces fit tightly together with no need for glue, and the printer has been producing consistent nice prints. It's very exciting to see these beautiful parts printed off a machine that was previously producing failed prints.

The next post will likely be about this frame, in its expected glorious completion.

MOTHERBOARD DESIGN

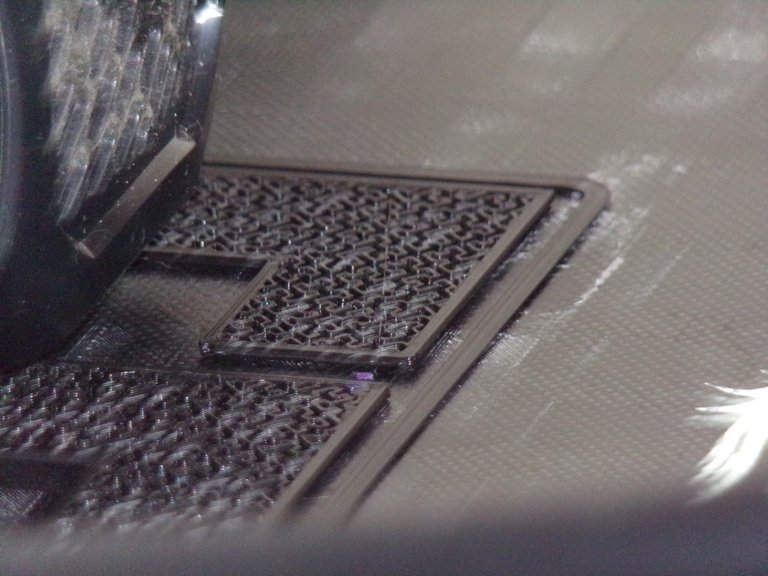

What the viewer will now see is a prototype (not the part that will be used.)

This is the bottom piece to the mobo case I have designed. This is a prototype and I have a very nice clear printed bottom piece, but I am going to save that reveal for the completed mobo case post ;)

There are obvious layer separations that have occured.

Reason:

Heat too low, speed to fast.

Printed @ 0.6 mm layer height with TECBEARS PLA, extruding filament faster, need for higher heat.

This will cause layer separation, and was the cause of this print coming out so horribly. I verified this to be the case later on. Darker filaments will oftentimes need higher heat, and utilizing temps for a previously used filament that may have required less, can cause this to happen.

Attention to these small details can be the difference with a big hunk of wasted filament, or a nice print.

Lesson learned!

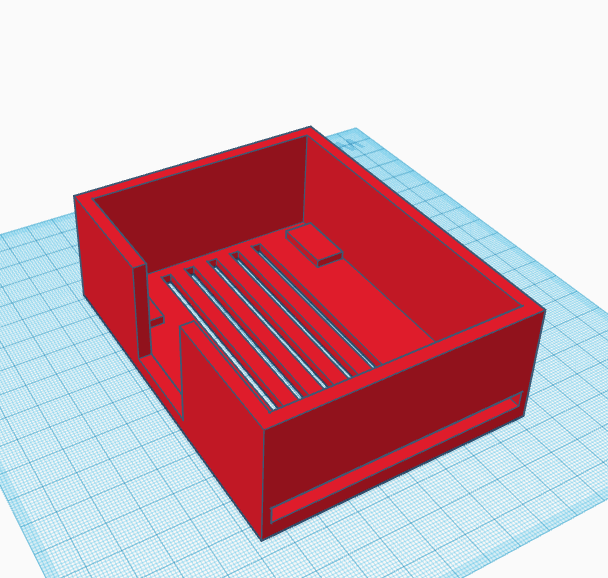

Here is the model in Tinkercad:

It is pretty simple.

I wanted ventilation on the bottom, a slot for the interfacing, and some feet to raise the board so it's not sitting flush on the bottom.

I opted to not place screw holes in, because of my addiction to using hot glue,

and I even forgot to add feet so I could have an excuse to use more hot glue :D

Actually forgetting the feet was a mistake that I think was a good mistake.

Not having feet added means I do not have to worry about supports, (wasted filament)

and can simply print small feet to glue on. There won't be any structural worries, as it just needs to hold a small PCB board.

and although for some this might be a gripe, I'm the designer and feel it is perfectly fine, so this is how things are going down.

More updates coming soon!

Thank you for stopping by,

Have a great day! ~~@print3dpro

You are doing well.

Thank you! Trying my best!

I wish I knew what you were talking about!!!!

Building mini indoor greenhouses from 3D printed parts! 😊

Hopefully I will have a post done soon (1-3 days) to show the completed result.

Thank you for stopping by my friend!

I knew you were building a mini indoor greenhouse, it's all the rest of the lingo I don't get. Filament is the raw material? Is it expensive?

I see what you mean. The posts aren't written in a way that would make sense to most people.

I think I might be able to improve this. Maybe if I do the first half of the post just describing what I am making in simple terms, then the second half describing technical aspects, this might be better.

Yes and yes. (at least I think it's pricey)

Rolls of filament can be compared to a giant roll of fishing line..

There are different compounds used, but I've only used PLA (polylactic acid)

which seems to be popularly used today because it's biodegradable but takes a while to break down. Made from corn starch compounds. Pretty wild stuff.

This is a photo of a standard size 1 kg roll (2.2 pounds) and run an average of 20 dollars per roll.

Depending on the type of item printed, if selling prints, it could be profitable.

This little self watering planter that I designed could sell for maybe 5-10 dollars and takes no more than 0.25 cents worth of filament, maybe even less but I don't remember and wasn't really paying attention to the calculated cost.

If someone is printing things just to print things, it could become a hobby that might cost an extra 20-100 dollars per month, + an increase in electric use, (not really sure how much because electric is included with my lease :)) with mountains of printed items piling up and laying around the house.

Lately I am thinking it might be a good idea to start designing things and selling on Etsy or Ebay or both maybe.

Hey people who are 3D printers don't need the extra explanation, just me! I'm sure your posts are plenty clear to them.

Selling things that need shipping is a pain in the neck.

I'm happy to explain as much as you would like to know! I remember you mentioned some interest with 3D printing, and one aspect that I find pretty cool is that the 3D printing community is generally really helpful and pleasant to communicate with.

I sold some collectable items on Ebay a couple of years ago and remember the shipping and handling to not be the most pleasant of experiences, you're definitely right about that, but there will be no way around it if I decide to sell things. To me it seems worth a try, because who couldn't use another income stream these days.

I've opened a store in my garage, on account of my move that never happens has to happen by August 31 now. I don't know where I am going! I can't find a place around here for less than $7000/month (I have special needs to consider) and our lake house is not really inhabitable long term.

Anyway, the store is great - I just sold a dang mop bucket. People come and get the crap. Whatever is left mid august will be donated, and that will be that. It's fun.

I'm happy to hear getting rid of things have been going smoothly for you. I remember reading about it on your blog too. It's impressive how much you've accomplished lately!

I hope you're able to find something accommodating at an affordable price soon. I looked online recently at rates for different apartments and everything seems to be increasing in price.

Around here, prices are ridiculous. NYS will be seeing the homeless rates of CA soon.

There are many things that I could not understand much since I don't have experience in this field like you but I like the design you are working on for indoor greenhouses. Its a good one and look forward to seeing the final version. thanks for the nice post

Congratulations @print3dpro! You have completed the following achievement on the Hive blockchain and have been rewarded with new badge(s) :

Your next payout target is 500 HP.

The unit is Hive Power equivalent because your rewards can be split into HP and HBD

You can view your badges on your board and compare yourself to others in the Ranking

If you no longer want to receive notifications, reply to this comment with the word

STOPTo support your work, I also upvoted your post!

Your content has been voted as a part of Encouragement program. Keep up the good work!

Use Ecency daily to boost your growth on platform!

Support Ecency

Vote for Proposal

Delegate HP and earn more

Neatly tuck in the whole board! Can't wait to see the end result!