3D Printed Funnels

Hello Everyone,

Lately the 3D printer has been working overtime, and my main objective is to print things that are useful, or referred to in the 3D printing world as "practical prints."

Being a cannabis cultivator as well, I like to incorporate 3D printing into my indoor gardening as much as possible. (My cannabis content can be seen on my main blog @futuremind)

I normally use tap water for my plants, but I don't appreciate all of the additives in tap water, and have been thinking of ways to collect rain water with some jugs I have laying around the apartment.

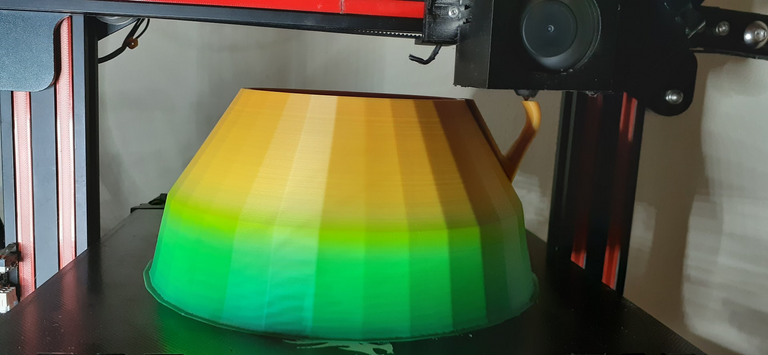

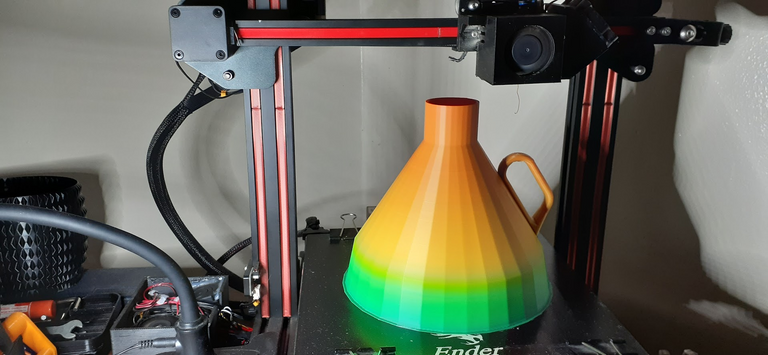

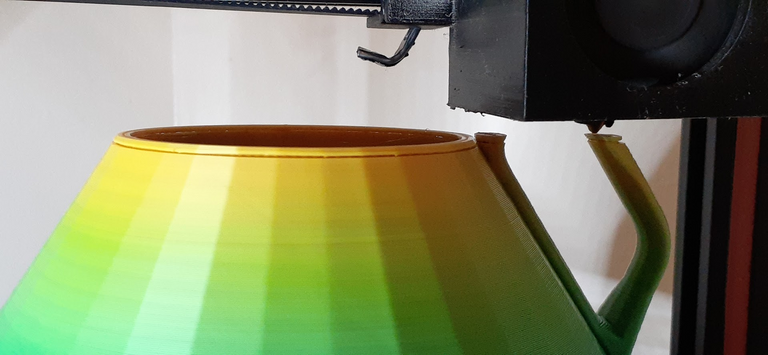

5 Gallon Water Jug Funnel With Handle, No supports needed by sokutaban April 23, 2020

Luck would have it that someone created a funnel for these 5 gallon jugs and uploaded the design to Thingiverse.

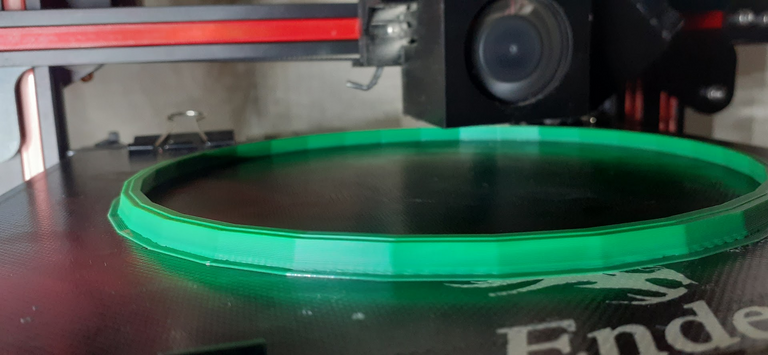

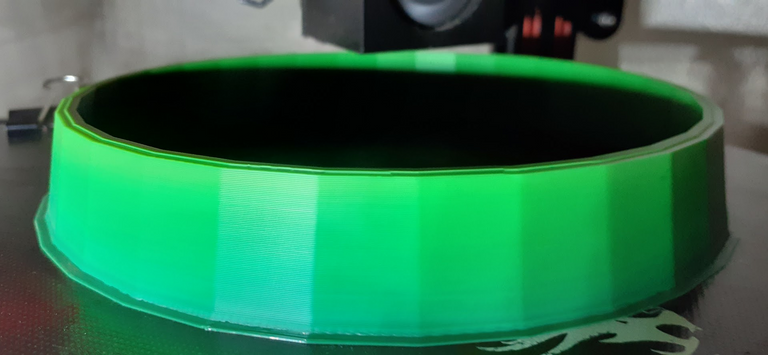

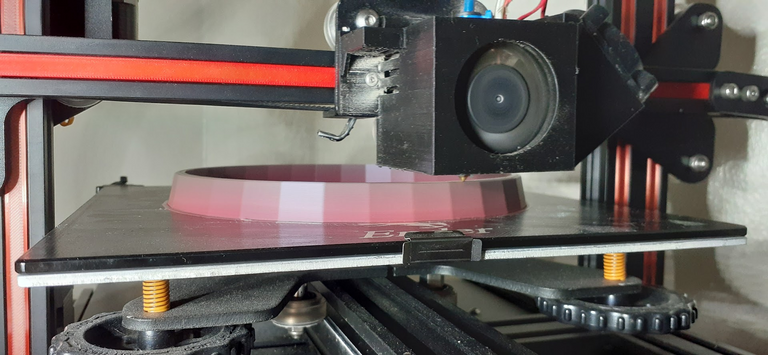

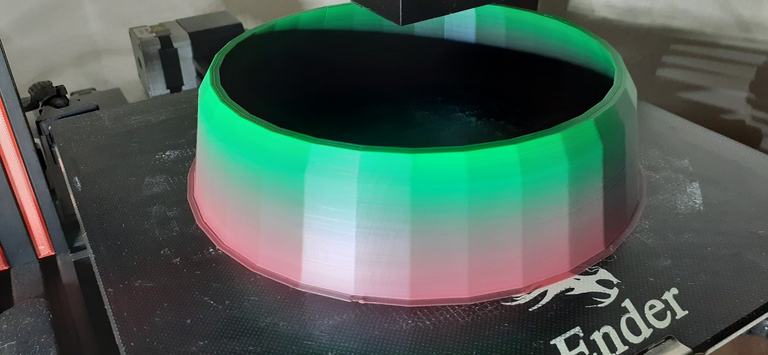

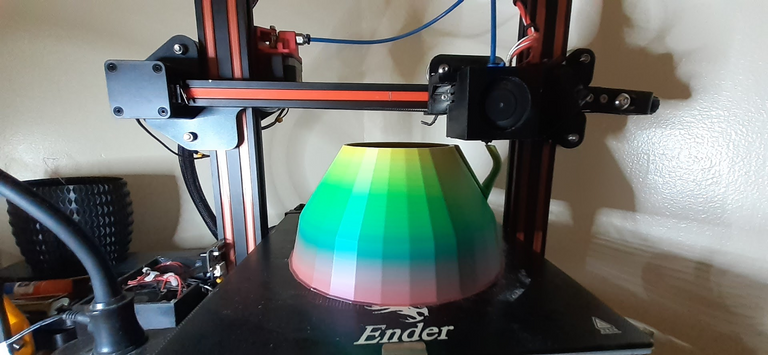

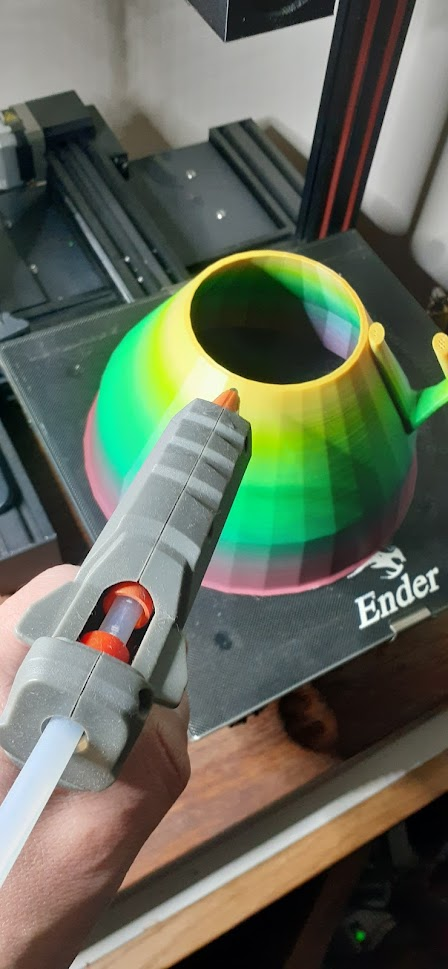

I opted to use my premo color change filament because I really like this stuff, and felt confident that these prints would complete without any issues.

At 0.2 mm layer height, this print took 18 hours, and the first one was a success!

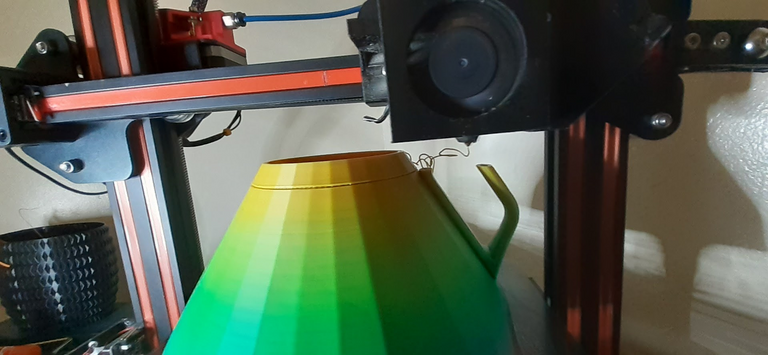

Then things went terribly wrong...

I woke up on the couch at this point. (I always sleep on the couch when printing, as a safety measure, (maintaining close proximity to the printer) instead of my comfortable bed. It's all about sacrifice sometimes.)

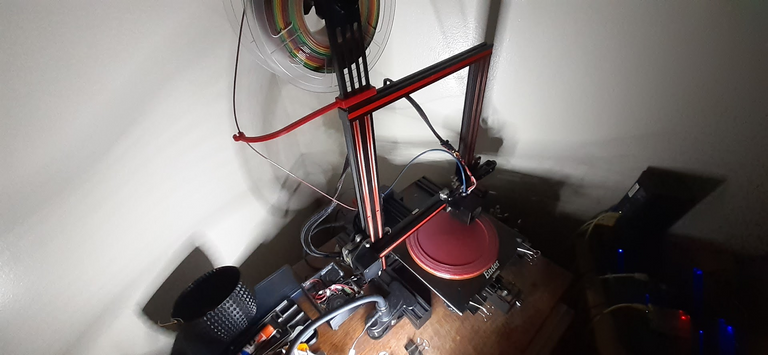

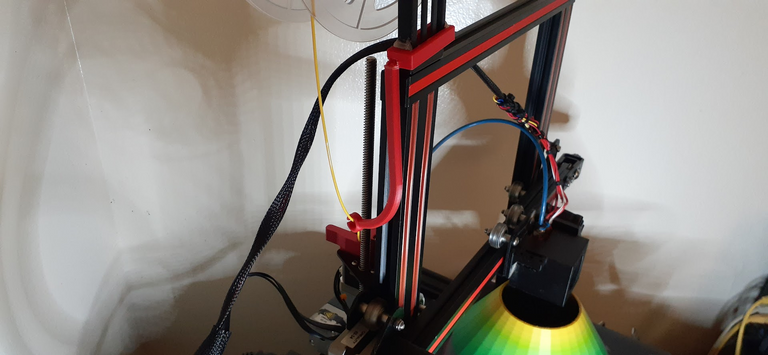

This image above is from my previous post, but I share it here because of that filament guide. I had been eyeing it and thinking "we have a problem, as this roll becomes smaller the angle and pressure increases on this weak guide. It is going to snap."

I was correct with my thinking.

It couldn't have happened at a worse time, as I was nearing the completion of this 5 dollar print. (Cost of the amount of filament used.)

Things went from bad to worse.

As if the causation of the missing layers was not bad enough...

Things became worse....

And I had to make a decision.

"Do I cancel the print, and waste all of this filament, or do I continue on and finish it under close observation and removal of the extruded filament as it completes?"

I decided the latter was the correct decision. Things got even worse from here!

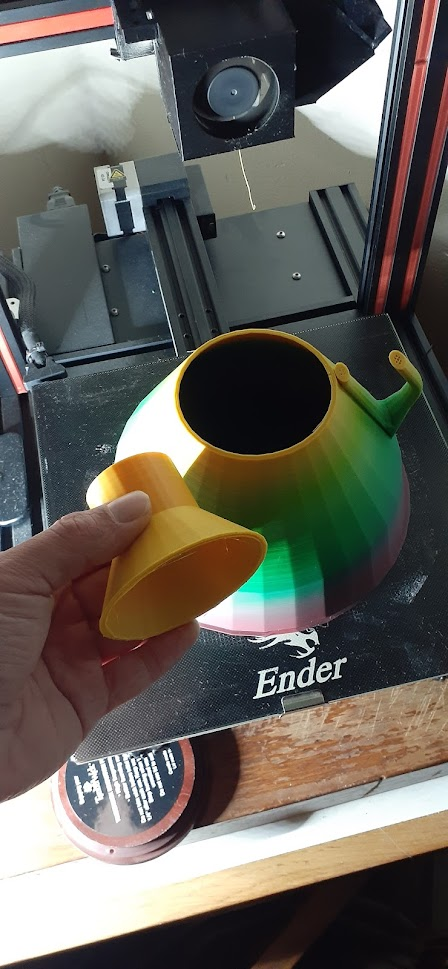

It finished fine, but that layer was a serious concern, and with a minimal tug...

I do not accept defeat at this point...

Can anyone guess how we fixed this?

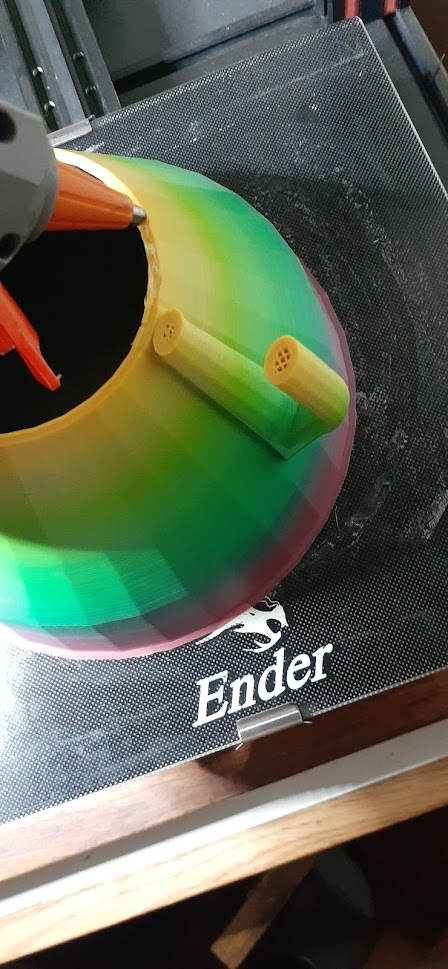

As @print3dpro's glue gun started creeping into the scene, I was feeling a bit of relief.

Ahhhhh hot gluuuuuuueeeeeee

Some might think I'm bugging a bit... but this is just to collect rain water people, so let's not go wasting 5 dollars worth of filament!

I'm pleased with the results. Sure, things could have gone better for the second funnel, but this is going to work.

And what great timing, as we are getting a nice steady rain currently :)

Overall, this is a success!

3D printing comes with unexpected challenges, as well as unexpected catastrophes at times.

Sometimes I'm able to see a problem getting ready to occur (as was the case here.) and other times it's not so obvious. I'm just happy this was a success in the end.

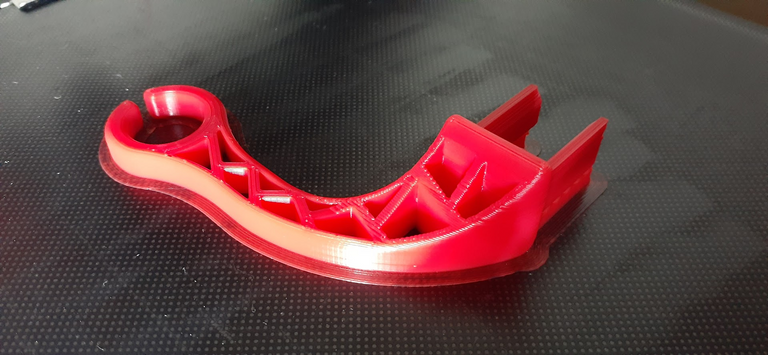

Filament Guide 2021 - Ender 3 / Pro by ElevationsTech November 01, 2019

As I finish writing this post, I have a nice filament guide sitting on the bedplate, ready for installation :)

This one looks much stronger than the previous filament guide, and I have little doubt that it will work just fine.

I'll snap a photo of this in the next post, as I don't think I'm going to dedicate an entire post to this filament guide, but I'll give it another mention anyway and show how it fits.

Thank you everyone for the amazing support and engagement! Your time is a valuable commodity, and I always keep this in mind and do my best to respond to everyone!

Thanks for stopping by, have a great day! ~~@print3dpro

Absolutely awesome job and why do you have to collect water?

Thank you my friend.

I don't necessarily have to collect it, but I think it would be healthier for my cannabis plants, instead of using the tap water :)

This just makes it easier to get a better collection in these jugs.

Personally I ran everything through a water filter to remove a bunch of the total dissolved solids.

Really helps on getting to be aware of the total dissolved solid numbers as well as your additions with fertilizers.

Great project!

Do you have a screen on top of the funnel to prevent dirt, leaves and bugs from getting in there?

A few "rain collector" designs exist to give you ideas:

https://www.yeggi.com/q/rain+collector/

https://cults3d.com/en/3d-model/tool/rain-collector

OOoo 3D printed Birdhouse & rain water collector:

https://www.stlfinder.com/model/bird-house-with-rain-water-collector-5tdrUBwV/2004085/

That's a great idea that I didn't even think about.

Thank you so much for the awesome resources and kind words my friend!

That's a pretty good way to collect water. If the big end of the funnel was even bigger, you might be able to collect a bit more water.

I suppose you have to work with the STL files that you have...

Thanks for stopping by @amberyooper,

Seems you know a thing or two about 3d printing :)

Yeah I can scale up the size from the raw .stl, but this will also increase the fitting size for the jug, rendering it too big lol. I was thinking the same thing though, a bigger funnel would be way better.

With Tinkercad.com this might actually be kind of easy to design with the basic shapes.. hmmm I might make more funnels in the future :)

I bet there's ways to modify just certain parts of a model, but I'm beginner with this design software still and haven't the slightest clue how to do it. I've been trying to figure it out though 😅

Have a good night :)

Yeah, I don't know how to use the design software either, but I talk to people who do 3-D printing so I've picked up some information about the process.

If you could just modify the big end of the funnel in the program to make it bigger, that might work.

JAJAJA amigo te acompaño y entiendo todo el sacrificio de estar atento a cualquier indicio de falla con la impresora, me ha tocado levantarme 3 0 4 veces en la madrugada para ver si los prototipos de mis clientes salían bien.

Justo hoy fallo mi maquina, así que toca darle mantenimiento.

Jajaja mi amigo. Mi impresora también falló hoy. Ya lo arregle.

Funciona bien ahora.

Gracias por tus lindas palabras mi amigo.

Nooo la correa, nunca (Toco madera) me fallo una correa, siempre problemas con el hotend

Bowden problemas? zuecos..

I've been wondering how much filament costs. $5 is a lot for a plastic funnel!

I love that idea to collect rainwater.

It runs about 20 dollars for a 1kg roll. So I could print about 4 of these from one roll.

I agree it's a bit much for a funnel. I need to stop messing around and get an income stream going.

Thanks for the kind words and support @owasco.

A certain amount of messing around is necessary to get that income stream going in the first place. You're in the development phase.

I need a hand pump for a five gallon bottle of water. Is that possible to make? We'll all need those when the power goes out.

https://www.amazon.com/Brio-Universal-Manual-Drinking-Silver/dp/B01LYRC3AR/ref=sr_1_8?keywords=water%2Bjug%2Bpump%2B5%2Bgallon&qid=1636901061&qsid=146-8463833-7911008&sr=8-8&sres=B07HFPC7HB%2CB07KVDGDTN%2CB07KW4TPNG%2CB01LYRC3AR%2CB08H4WMK37%2CB08L3DGGVL%2CB00APU2Y8Q%2CB096WV7FJR%2CB07YQXTLCZ%2CB07QZJXPX1%2CB07Y4D3P1J%2CB092311Y4Y%2CB099N7NJC2%2CB07TRP3N5X%2CB07RXH1TNB%2CB07NRYR6B6%2CB092379FY9%2CB083JPY6BF%2CB08HN56D5H%2CB07Y4S74RJ&srpt=WATER_DISPENSER&th=1

Yeah I would say that's a pretty accurate assessment, "development phase" indeed.

I do feel like I'm pretty close to being able to mass produce things without much worry of my machine going haywire. It's been a heck of a lot of work but it's so rewarding and fulfilling, from a non financial perspective anyway lol.

This might be possible yes, or a variation which serves the same purpose. It would probably take multiple parts and some springs, but definitely possible.

It would make for a fun engineering project for me that would definitely increase my skillz :D

I'll see what I can do :) Might take a while though, if you're in a hurry, best to just order one 😅

Thanks my friend, I can definitely print you some basic garden supplies and little gardening pots if you want, and that wouldn't take me very long, could even mail them to you no problem :)

You the sweetest. In the spring, when I'm going through my supplies, I'll let you know. I think I will more need 3" to 6" pots.

I haven't even been able to get the water to this one horse town. The company can't find the town or something. I'm determined to get this water for my prepping. And yes, I'll get a pump, but I really think I will need three. The water dispenser is electric, bottom load though, so I can get the much cheaper 5 gallon bottles, but no power no water, at least not easily. I'm also converting a stupid rinky-dink gas fireplace back to wood burning, and as a larger stove. I'm really looking forward to that. It's fun living in a house I want to take care of for a change. The last one I did not love.

Ok. Wasn't really expect that to happen. I was thinking with the guide it should make the print even smoother. Does the filament snapped when that happened? Also, if the guide is pulling the filament too far(when the drum rolling smaller as the filament running out), does it mean if we add a hinge to the guide and add a spring to it, to allow it to contract when the filament roll running smaller? Not sure if I deliver the message correctly, but my mind has been thinking of the VHS tape, the guiding roller has a spring to it, so when the movie starts it doesn't play too slow with deep voice, nor play too fast towards the end with chipmunks voice.

You're a smart dude bro ;)

Yeah the roll becoming smaller increases the angle and resistance. The filament snapping was not an issue, just the fact that the slim guide protruding out was feeling more and more resistance as the spool became smaller, and I was watching it, just waiting for the inevitable snap to occur.

I printed a two part solution that I will outline in the next post and will address in greater detail what you mentioned here. Thanks for the support my friend.

Nice.. followed you 💕

Thank you! Followed you too, with both of my accounts :) 💕