Nozzle Change

Hello Everyone,

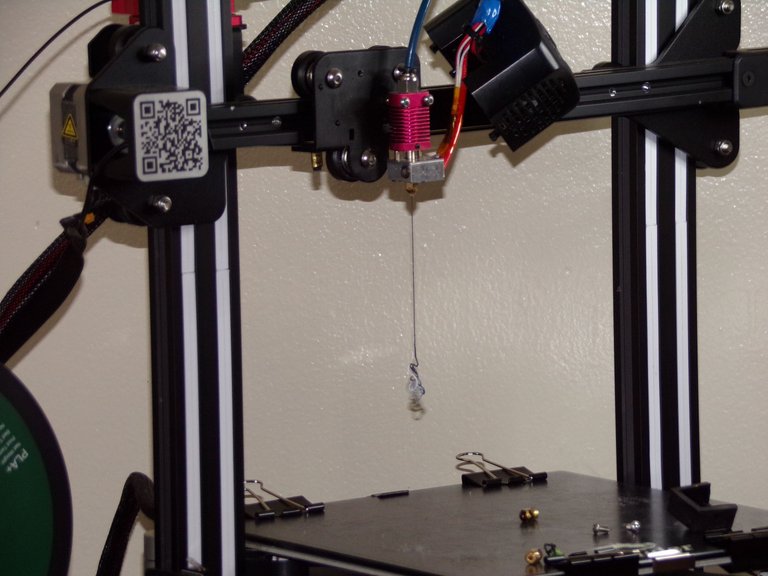

Today I'm preparing for calibration on the Ender 3 V2.

Specifically retraction, which I will discuss in further detail later in this blog.

But to calibrate retraction, we will need to change nozzles first.

Some questions might be:

"Why would one want to change nozzles, for what purpose, are they different sizes?"

Yes they are different sizes, measured in millimeters. Larger sizes will push more filament through, making way for faster printing, but with less fine detail.

With larger diameters, calibration will become moot for the lower diameters and different slicer profiles will need to be saved.

Previously I was printing with an 0.8 mm nozzle, and in this photo above, the reader will see multiple sizes that are on a printed holder on my printer. (it was printed with an 0.4 mm nozzle @ 0.12 mm layer height.)

"What does removing a nozzle entail?"

One might ask..

Heat and a wrench.. Preferably a plastic/rubber handled non heat conductive wrench..

The Fluidd Dashboard is the control grid, powered by Raspberry Pi. What the reader will now witness is a remote connection via my home network to access the Fluidd Pi control station.

This is the control station or central nervous system if you will. All the jobs are uploaded through this dashboard, and there are a plethora of user controls that are accessible which will override G-code parameters. (Emergency shut down, speed control, temp control, etc.)

You will notice the Extruder temp is 181.7 C.

180 C is the minimum temperature that most PLA will begin to melt at.

When manually pushing the filament through, the operator of the printer will gain a much more comprehensive "feel" for the filament, and will know which temps are the most suitable for printing through trial and error.

After the nozzle has been heated, the process is very straight forward for the mechanically inclined.

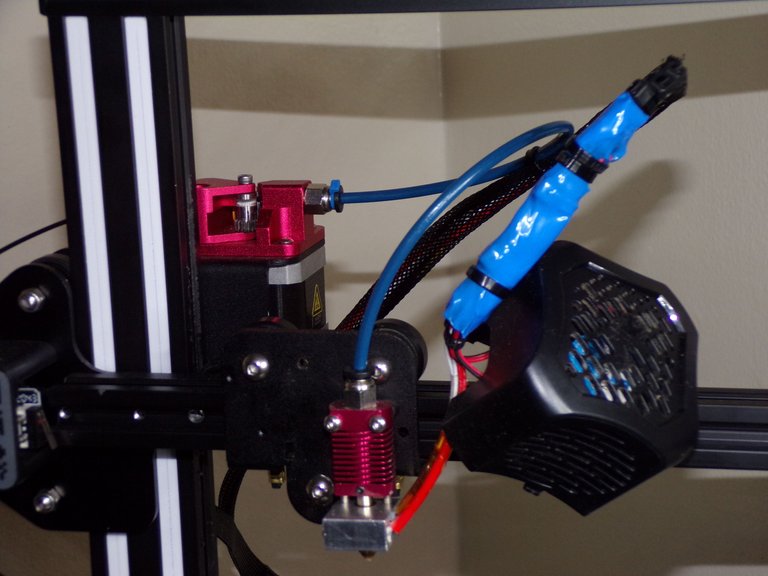

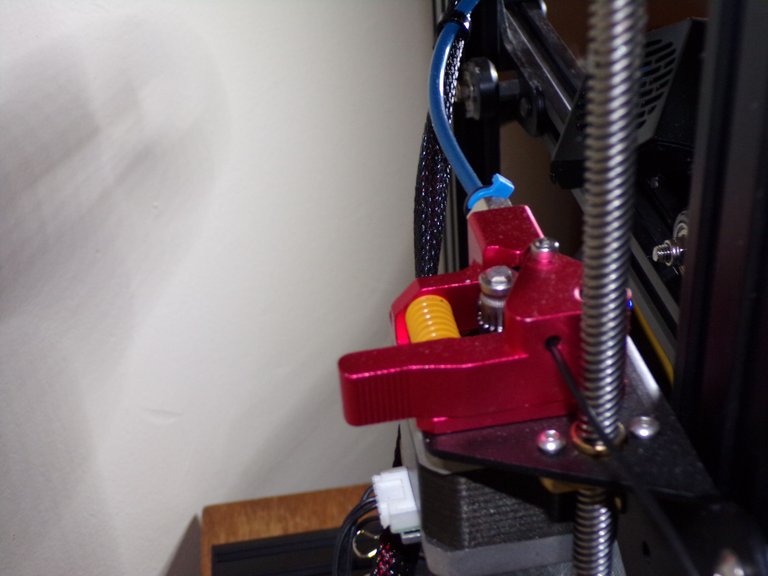

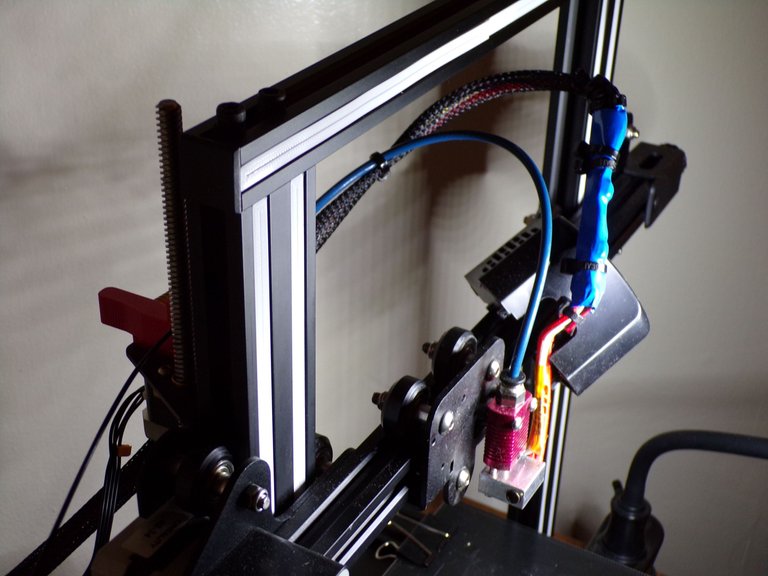

Here are some photographs of the hot end fixture assembly broken down for nozzle swap.

The nozzle connects to this heated hot end, and the hot end is connected to the extruder (the other red component up top), and that blue tube is called a bowden tube.

The bowden tube is more critical than many would guess, it feeds the filament to the hot end by way of an e-step motor (Which requires calibration!)

These parts work together for retraction which is a "push/pull" operation on the filament that reduces blobbing and stringing. I will dedicate entire posts to this calibration later in the blog.

Extruder

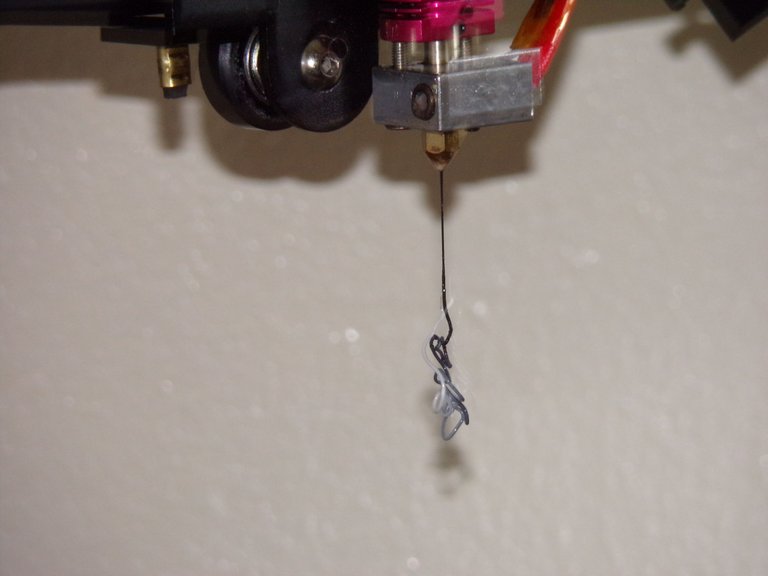

Once the new nozzle is inserted, you can give the filament a little push through the bowden tube, and if still heated, you will see oozing. There should be no obstructions, and the ooze should flow easily. The only thing that should stop the easy flow is lack of heat. If the nozzle is heated and you cannot push the filament through, this is indicative of a clog.

That's it for nozzle changing folks! It's not as hard as it looks, but be careful because it's easy to get burned from hot metal!

Have a great day and thanks for stopping by!

@print3dpro

Congratulations @print3dpro! You have completed the following achievement on the Hive blockchain and have been rewarded with new badge(s) :

Your next target is to reach 100 upvotes.

Your next target is to reach 50 upvotes.

Your next target is to reach 50 comments.

Your next target is to reach 50 replies.

You can view your badges on your board and compare yourself to others in the Ranking

If you no longer want to receive notifications, reply to this comment with the word

STOPSupport the HiveBuzz project. Vote for our proposal!

Thank you @hivebuzz!

You are welcome @print3dpro! It is great to see you are doing your first steps! Great work!

Your content has been voted as a part of Encouragement program. Keep up the good work!

Use Ecency daily to boost your growth on platform!

Support Ecency

Vote for Proposal

Delegate HP and earn more

Thank you @ecency!

Question, how often do you need to clean the nozzle. Is there any specific requirement or procedure? Probably stupid to ask, because print time, print heat, printing material and physical geometry of the print object may differ, but would like to know just in general how to determine if it's time to clean?

Hey that's a good question!

I've only printed with PLA so far, and my experience with this compound is, there isn't much need for cleaning at all..

The PLA can gunk up on the nozzle a bit, but when heating the nozzle, one can take a pair of tweezers and remove any filament residue.

There's also a rubber fitting that snugs over the nozzle on this hot end, which is nice because it limits the amount of gunk up.

There's always a little bit of PLA left in the nozzle after it cools, and this is the reason it's necessary to heat the block before nozzle removal, because otherwise you will literally be trying to break hard PLA with removal while adding extra pressure to the entire hot end.

In this sense it would not ever be recommended to remove a nozzle cold.

I swapped from 0.8 mm to 0.4 mm so that I may calibrate for higher resolution prints :)

Thank you for the great feedback!

I usually print with the same nozzle for a couple months at a time, until it's time to replace the nozzle. It's usually time to swap nozzles when print quality degrades.

Thank you for the answer. That however stir up another question, which makes you use the same nozzle without cleaning it on a regular basis, until the print quality degrade and you changed to another nozzle?

I do have some super thin needles for cleaning nozzles, which does work for clearing blockages. However, I've found that a good, solid cold pull does a better job of removing any leftover filament before it becomes an issue where cleaning is needed.

Make sense too. Thanks for answering.

My one pro tip would be to grab a 6mm spanner from the local hardware store. It works far better than the stamped metal one they give you.

Thank you! And the nozzle heats it up very fast too. I was burning my hand every time 😅

I currently use the wrench that's in my profile photo, it works rather great for nozzle swaps.

Thanks for the feedback!

Do you have a second wrench for grabbing onto the hot block?