Did you know plastic waste can be converted into fuel?

Plastic pyrolysis is a process that converts plastic waste into usable fuel.

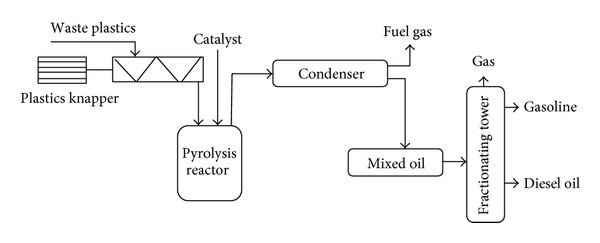

Here's how it works:

First is step is the obviously one, plastic waste needs to be collected, once a large amount of plastic is collected it has to be cleaned, the cleaner your plastic the cleaner your fuel, now we can pop it into the Plastic Pyrolysis Machine.

Oh wait, we need to build one first!

Here is my step-by-step guide to creating your own Plastic Pyrolysis Machine.

First thing we need is a reactor chamber to hold the plastic while it burns and this chamber needs to be built to handle high heat, there are many heat resilient solvents that can be added to your chamber to make it heat resistant. The reactor chamber needs to have a outlet for vapors and a hatch to safely load plastic.

Next step is to build the heating system, you can do this with conventional heating coils or attaching your reactor chamber to a furnace. The most important part is to ensure the heat is distributed evenly throughout your furnace, this can be done with ceramic wool.

Okay now onto the condenser, attach a pipe to the gas outlet we created earlier on the reactor attach this pipe to the condenser, coiled metal tubing for efficient cooling and submerge it in a water bath or use air-cooled fans.

Next we will make the gas reuse system, Install a pipeline to redirect excess syngas back to the heating system for energy efficiency. It is very important Include a flare stack as a backup for safely burning excess gas.

Lastly, we build the collection tanks also known as the fractionating tower, we need these containers to collect condensed liquid fuel, natural gas, and diesel. Provide a separate area to collect char and manage solid residues. The char is an organic material created from this process that can be used as a plant super-food. Imagine that creating plant food from plastic waste! PPO fuel or fuel created from the plastic pyrolysis operation is lighter and burns up to 50% cleaner than traditional fossil fuels. Oh I almost forgot, its safe to put in your car.

Here is a brief overview of the materials you will need:Stainless steel or iron for the reactor.

Coiled tubing (copper or steel) for the condenser.

Heat-resistant seals and gaskets.

Thermocouples for temperature monitoring.

Insulation materials like ceramic wool.

Pumps or piping for vapor and liquid transfer.

The most important thing above all is that people are safe while building and using their Plastic Pryolysis Machine.

Ensure all joints are gas tight if you already checked, check two more times, and include pressure relief mechanisms.

Another consideration although costly is adding emission control systems to your Plastic Pryolysis Machine in order to reduce pollutants exuding from your machine. The machines syngas system is a way to reuse these emissions as fuel for the machine, but the machine will still produce pollutants, you are burning plastic after all, hehe. I am not saying this solution is perfect, however, I do believe it is a way to remove plastic waste from our world and create an alternative energy source. I was intentionally vague about some steps, but if you have the will it is very easy to fill in the gaps. Just research plastic pryolysis.

If you read this far you will be happy know this will be part of a daily series I dubbed the Daily Did You Know. I will feature different articles about science, history, archaeology, space habitation and life systems in hopes to tell you something you didn't know. 😊

Tinker on my friends!

-Joziah

Posted Using INLEO

Congratulations @wedacoalition! You have completed the following achievement on the Hive blockchain And have been rewarded with New badge(s)

Your next target is to reach 600 comments.

You can view your badges on your board and compare yourself to others in the Ranking

If you no longer want to receive notifications, reply to this comment with the word

STOPCongratulations @wedacoalition! You received a personal badge!

You can view your badges on your board and compare yourself to others in the Ranking