Workover Techniques: The Concept of Hydraulic Fracturing and Well Stimulation

In Petroleum Engineering, there are several specializations or subsets and one of them is Production Engineering. Petroleum production engineering has to do with the designing and selection of sub-surface equipment for the production of oil and gas from oil wells. Petroleum engineers are also burdened with estimating and monitoring the amount in barrels of oil that will be produced daily or weekly from a particular well. Note worthy is that, petroleum production engineers could be from other technical fields like mechanical engineering.

However, petroleum production engineers often do encounter some well problems ranging from formation damage, lost circulation, excessive reservoir pressure, kick and many others during the production of oil and gas well fluids. Some well problems could lead to low productivity or well abandonment. This article seeks to discuss one of the methods or ways of attending to oil and/or gas well problems and it is known as "Workover Techniques."

In simple terms, a workover operation or technique is any remedial operation or variety of curative/remedial operations being done on a producing or shut-in well for the purpose of increasing or restore production from that well. According to Wikipedia,

The term workover is used to refer to any kind of oil well intervention involving invasive techniques, such as wireline, coiled tubing or snubbing. More specifically, a workover refers to the expensive process of pulling and replacing completion or production hardware in order to extend the life of the well.

Well workover is mostly necessitated following the unsuitability of the completion in a particular well. This implies that in cases where the production tubings and downhole components such as; valves and pumps are being damaged or become faulty, workover operations could be employed though it is very complex and expensive.

Also, AAPG has it at that workovers may be required for one or more of the following reasons: Unsatisfactory production or injection rates, supplemental recovery project requirements, regulatory requirements, competitive drainage, reservoir data gathering, lease requirements and abandonments etc. But ultimately, majority of workovers are done because the well is performing below its capacity and expectations.

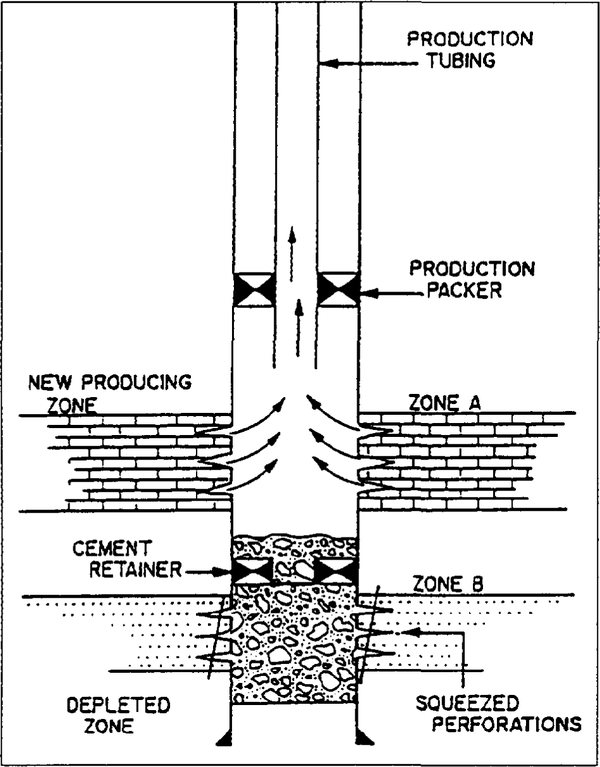

Basically, there are many ways of carrying out workover operations in order to maintain or increase an oil or gas well productivity and some are; Well Stimulation, Recompletion and Routine Maintenance Work. The latter mostly includes mechanical repairs to damaged working parts, part replacements when pump parts wear out and clean out of sand from the well amongst others. While recompletion has to do with the work done to shut off an existing zone that was no more producing in order to open a new zone. Recompletion work varies depending on the position of the new zone to be opened - above or below the existing zone.

Source

On the other hand, well stimulation is often done either through hydraulic fracturing, or acidizing. On the whole, workover techniques are:

- hydraulic fracturing

- scale removal

- acidizing

- parrafin removal

- sand control

- reperforation

- emulsion

- water block

Well Stimulation

Talking of stimulating a well, it refers to any operation done on an oil and/or gas well so as to improve its performance. By performance, we mean its productivity rate. Well stimulation helps to reduce formage damage around the wellbore and it is achieved either through acidizing or fracturing like earlier stated.

Stimulating a Well by Hydraulic Fracturing

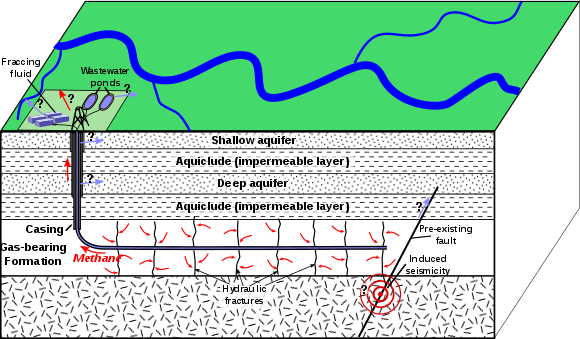

image source: wikimedia

Normally, fracturing talks about puncturing, cracking, hole, channels and vents creation. Hence, hydraulic fracturing entails an operation where a unique blended liquid is being pumped into a well and into a formation under pressure high enough to cause the formation to crack open, creating channels through which oil can flow into the wellbore.

It is simply the pumping in of a pressurized fluid into the well to create openings in the formation for fluids invasion into the wellbore from the formation. The channels created are held open by sand. These fluids known as frack fluids are basically water, containing sand or other proppants suspended with the aid of thickening agents. There are three major processes to hydraulic fracturing which are fracture initiation, fracture extension and fracture propping.

Hydraulic fracturing began as an experiment in 1947, and the first commercially successful application followed in 1950. As of 2012, 2.5 million "frac jobs" had been performed worldwide on oil and gas wells; over one million of those within the U.S. Such treatment is generally necessary to achieve adequate flow rates in shale gas, tight gas, tight oil, and coal seam gas wells. Some hydraulic fractures can form naturally in certain veins or dikes. source

Acid fracturing on the other involves the same considerations as hydraulic fracturing except that the conductivity is generated by removing portions of the fracture with acid, leaving etched channels after fracture closure.

Workover techniques such as hydraulic fracturing and well stimulation has always proved useful in terms of increasing or improving the productivity of a well.

References

https://en.m.wikipedia.org/wiki/Petroleum_production_engineering

https://en.m.wikipedia.org/wiki/Workover

https://wiki.aapg.org/Workovers

https://en.m.wikipedia.org/wiki/Hydraulic_fracturing

https://www.glossary.oilfield.slb.com/en/Terms/f/frac_fluid.aspx

@steemstem has been set as beneficiary!!

Thanks for your contribution to the STEMsocial community. Feel free to join us on discord to get to know the rest of us!

Please consider supporting our funding proposal, approving our witness (@stem.witness) or delegating to the @stemsocial account (for some ROI).

Thanks for including @stemsocial as a beneficiary, which gives you stronger support. Using the STEMsocial app could yield even more supporti next time.