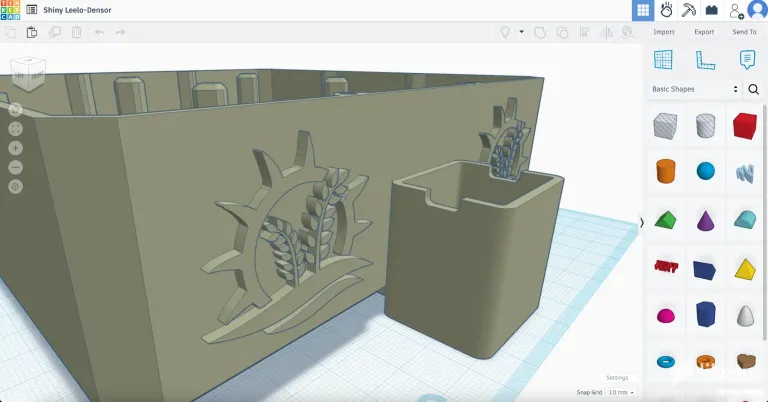

First Logo Prototypes For Moss Rock Farms Hydroponics Gear

This week was more swimming in the 3D printing pool. I finally got started messing around with Tinkercad, which is a free online 3D modeling program, and learned how to emboss and engrave my logo in the products. These are prototypes that I am going to use in my own greenhouse and will be making content using them and showing people how they can grow their own food with my products.

First up is the filling module cap for my big modular hydroponics unit that I have been working on. All the pieces are finally printed, and I have been working on the finishing touches with sandpaper and a dremel tool. I got all the holes in the cooler cut out and just waiting now on the funds for me to order the water pump and hose, then it's ready to go! I am excited to get the greenhouse this week and get it up so that I can get all this going outside!

Next I have the seed starting stations which has the image part of my logo in two spots across the front. I like the balance with having them on both sides. I am considering painting them with the colors of the logo to give it some depth, but that will be apart of the finishing process.

Still working on dialing in the printers so they are the best quality I can get. I am getting there, but this whole thing has been an awesome education as I have been going along. Sure I have wasted some filament on some failed prints, but each of those has taught me a lesson. That's why all the prints I have done so far are going to be what I use here, haha. I hope to get everything perfected by the time I am ready for customer production. I need 2 more of those filament dryer boxes. I am going to get 2 1-roll dryer boxes to use for the other 2 printers. I have my main upgraded printer set up with the dual box that I got this week that is going to serve as my multicolor printer. This really just means my black and green filaments. These particular printers won't do multicolor prints. It gives me a way to switch them out easily. The other 2 printers are going to stay with printing white filament for all the bases and big modules.

Anyway, just a little Saturday update from the farm. I am really excited with this new journey and think that it can really grow once I get things perfected.

Until next time,

Be cool, be real, and always abide my dudes!

For the best experience view this post on Liketu

Reminds me of my time in Horticulture class in high school. That's where I first learned about aphids after an infestation broke out in one of our greenhouses. Ah... those were the days!

I'm seeinf more and more of these printers being used, and even saw a documentary where one was used to build a house! Technology is amazing.

Oh yeah! To me, I look at 3D printing as decentralized manufacturing, lol. I have seen the show that talks about the 3D printed houses, I think it’s brilliant myself. I am loving being able to make whatever I need, as long as it can be made of plastic and some minor hardware, lol.

Currently have a suppressor for my .22lr on the printer now. Tested one version but didn’t read the instructions fully that said to print the housing horizontal vs vertical and had a mishap, but the first couple of shots were great until the end blew off because of a weak layer, the reason I needed to print horizontally, 😂

But hey, that’s a whole part of the learning process, lol. At least it didnt blow up in my face, 😂

Gardening products are way safer, lol, but gun parts are just fun, lol. My buddy built a six figure drone business with his printer farm, so at least I have a guide other than just online resources.