Soldadura electronica con estaño // electronic welding

Hola compañeros de hive hoy para empezar el post tengo una pregunta :

¿ Que es soldar?

Soldar es unir dos piezas, metálicas en este caso, aportando un material que será el encargado de realizar esa unión. Para estos trabajos utilizaremos estaño, que es un metal con un punto de fusión bajo, con lo que dando calor con el soldador en la zona a soldar, el estaño se fundirá y unirá los elementos que estén en contacto con él.

La función de la soldadura es fijar los componentes entre si o sobre placas de circuito impreso y sobre todo, asegurar su perfecto contacto eléctrico.

El modelo de soldador (también llamada cautín en el continente americano) será de más o menos potencia y con un determinado modelo de punta, pendiendo del tipo de componentes a soldar. No obstante, y de manera genérica se puede recomendar un soldador tipo lápiz de en torno a 30 Watts, y si estamos tratando de soldar componentes electrónicos de uso normal, una punta mediana o fina.

El estaño (Sn) es un componente crucial en la soldadura electrónica debido a sus propiedades físicas y químicas que lo hacen ideal para unir componentes electrónicos. Aquí te explico sus funciones principales:

Baja temperatura de fusión: El estaño tiene una temperatura de fusión relativamente baja (231.9°C), lo cual es beneficioso porque permite fundir y unir componentes electrónicos sin dañarlos debido a altas temperaturas.

Buena conductividad eléctrica: El estaño es un buen conductor eléctrico, lo cual es esencial para mantener la integridad de las conexiones en circuitos electrónicos.

Propiedades mecánicas adecuadas: El estaño proporciona una unión fuerte y duradera que es resistente a las vibraciones y los impactos mecánicos. Además, las soldaduras de estaño tienen una buena ductilidad, lo que les permite absorber cierto grado de estrés sin romperse.

Compatibilidad con otros metales: El estaño se alea bien con otros metales como el plomo, formando aleaciones de soldadura (como la popular soldadura 60/40, que contiene 60% de estaño y 40% de plomo) que combinan las propiedades de ambos metales para mejorar la soldabilidad y la resistencia de las uniones.

Resistencia a la corrosión: El estaño es relativamente resistente a la corrosión, lo cual ayuda a proteger las uniones soldadas y a mantener la conductividad a lo largo del tiempo.

Tensión superficial adecuada: El estaño tiene una tensión superficial que permite que la soldadura fluya bien y se adhiera adecuadamente a las superficies de los componentes electrónicos.

Para garantizar una buena soldadura es necesario que tanto el estaño como el elemento a soldar alcancen una temperatura determinada, si esta temperatura no se alcanza se produce el fenómeno denominado soldadura fría.

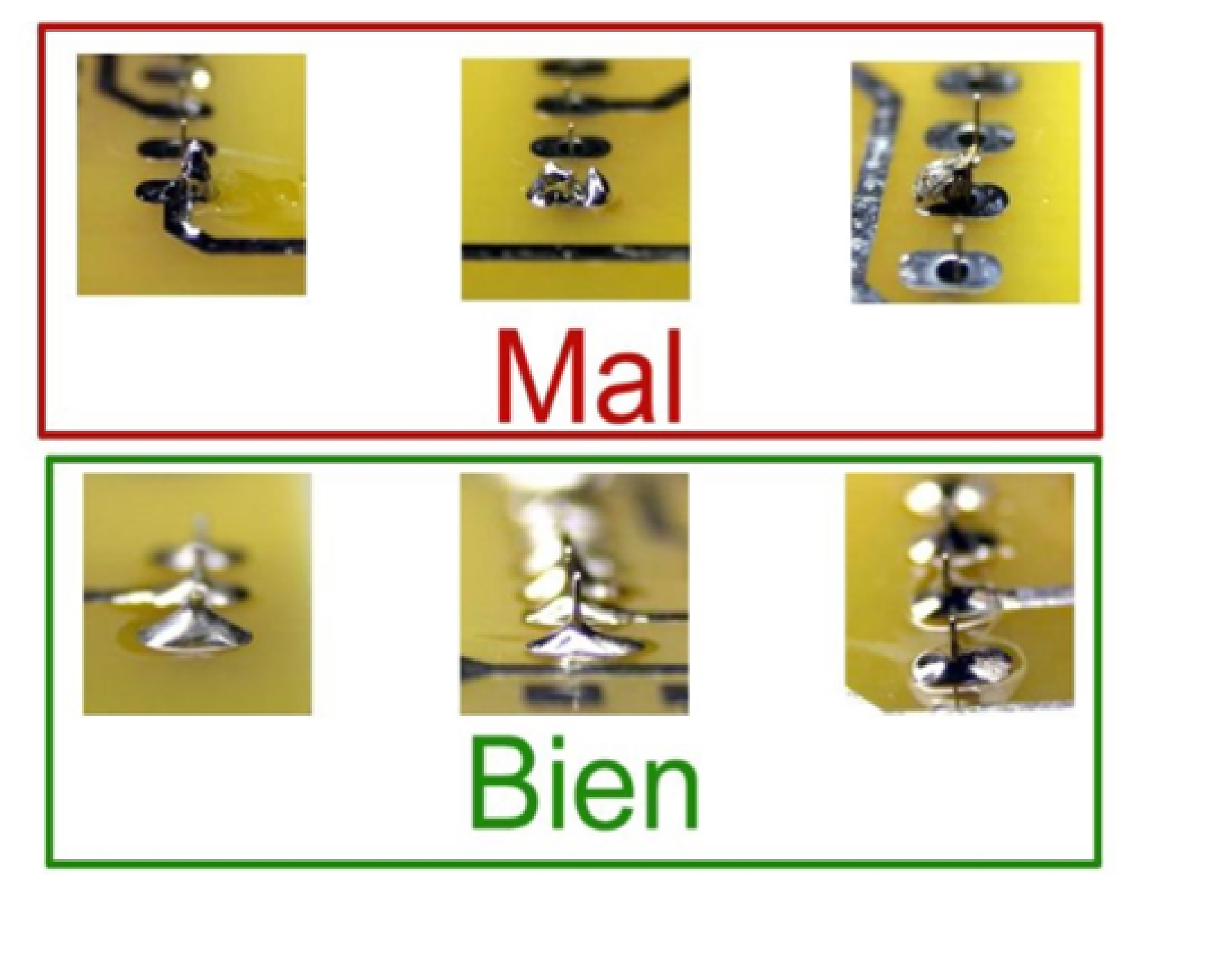

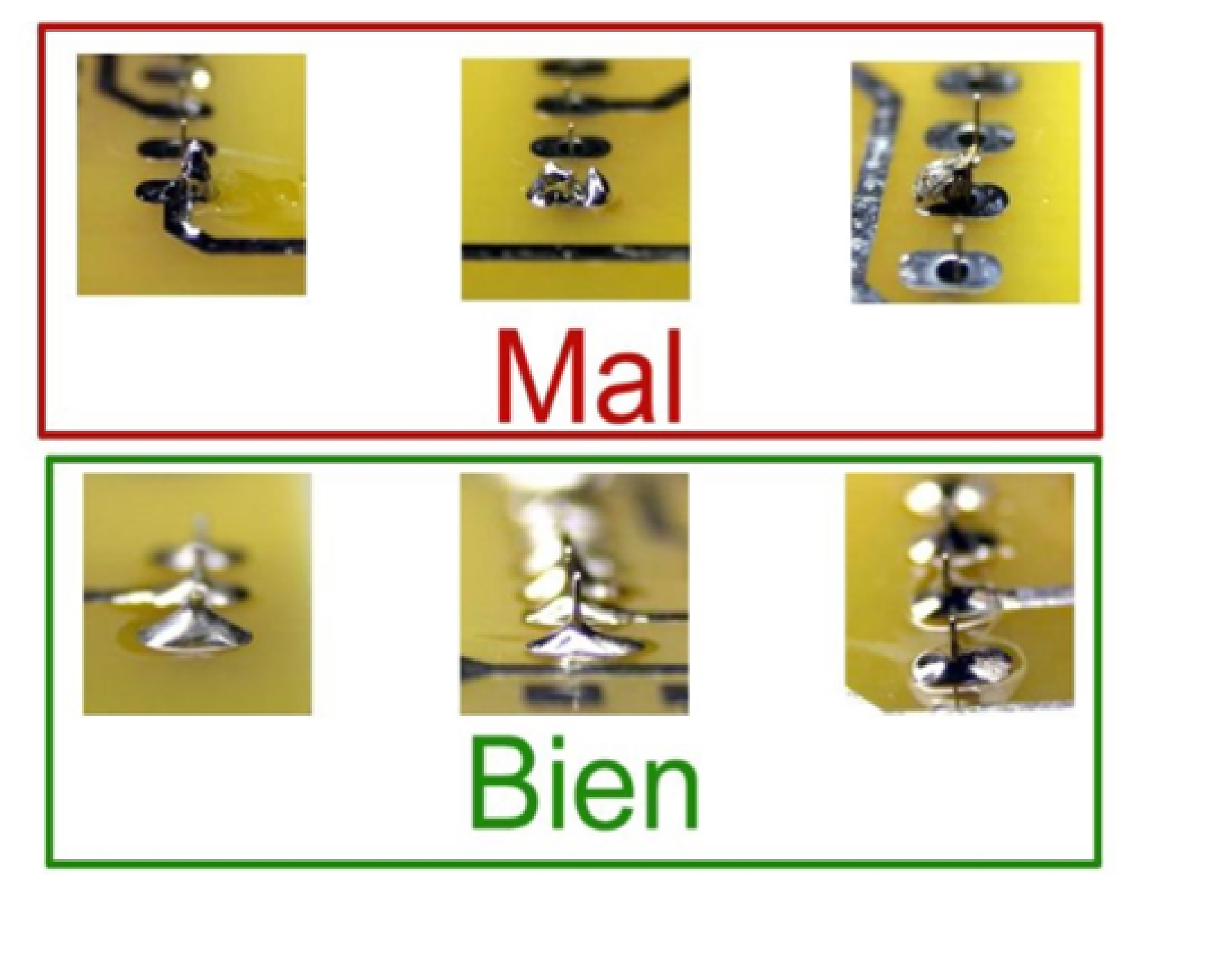

Ejemplos de buenas y malas soldaduras:

..............................................................................................

Hello hive colleagues, today to start the post I have a question:

What is welding?

Welding is joining two pieces, metallic in this case, providing a material that will be responsible for making that union. For these works we will use tin, which is a metal with a low melting point, so by giving heat with the soldering iron in the area to be soldered, the tin will melt and join the elements that are in contact with it.

The function of soldering is to fix the components to each other or to printed circuit boards and, above all, to ensure their perfect electrical contact.

The soldering iron model (also called a soldering iron on the American continent) will be of more or less power and with a certain tip model, depending on the type of components to be soldered. However, and in a generic way, a pencil-type soldering iron of around 30 Watts can be recommended, and if we are trying to solder electronic components for normal use, a medium or fine tip.

Tin (Sn) is a crucial component in electronic soldering due to its physical and chemical properties that make it ideal for joining electronic components. Here I explain its main functions:

Low melting temperature: Tin has a relatively low melting temperature (231.9°C), which is beneficial because it allows electronic components to be melted and joined without damaging them due to high temperatures.

Good electrical conductivity: Tin is a good electrical conductor, which is essential for maintaining the integrity of connections in electronic circuits.

Suitable mechanical properties: Tin provides a strong, durable bond that is resistant to vibration and mechanical impacts. Additionally, tin solders have good ductility, allowing them to absorb a certain degree of stress without breaking.

Compatibility with other metals: Tin alloys well with other metals such as lead, forming solder alloys (such as the popular 60/40 solder, which contains 60% tin and 40% lead) that combine the properties of both metals to improve the weldability and strength of the joints.

Corrosion resistance: Tin is relatively resistant to corrosion, which helps protect solder joints and maintain conductivity over time.

Proper Surface Tension: Tin has a surface tension that allows solder to flow well and adhere properly to the surfaces of electronic components.

To guarantee a good solder, it is necessary that both the tin and the element to be soldered reach a certain temperature; if this temperature is not reached, the phenomenon called cold soldering occurs.

Examples of good and bad welds:

Congratulations @tecnotronics! You have completed the following achievement on the Hive blockchain And have been rewarded with New badge(s)

Your next target is to reach 50 posts.

You can view your badges on your board and compare yourself to others in the Ranking

If you no longer want to receive notifications, reply to this comment with the word

STOPCheck out our last posts:

Thanks for your contribution to the STEMsocial community. Feel free to join us on discord to get to know the rest of us!

Please consider delegating to the @stemsocial account (85% of the curation rewards are returned).

You may also include @stemsocial as a beneficiary of the rewards of this post to get a stronger support.

Nice seeing a post about that! Maybe i will consider that in my next need doing that.

Thanks for commenting, electronic welding is a very interesting topic.