First Snow, Leather Crafts, Electroforming Trials & Alchemy Setup

Today we had our First Snow this Winter, also the very first time that Salsa experienced Snow. We all got out into our Garden this freezing morning to admire the white beauty, Iulia didn't miss a chance to capture a few beautiful shots from the Garden & Our Dogs. Kymia & Salsa played with enthusiasm & excitement in the transformed landscape. We breathed in some refreshing & recharging air before we started our day getting creative.

Today Iulia wanted to stitch some more Leather, but at some point the Sewing Machine was giving us quite a bit of headache. It's quite a finicky machine, being 75+ years old & while she can be fitted with a leather sewing needle, she is not really intended for Leatherworks, at times she stitches smoothly but today was one of those days where she kept refusing to stitch properly, thread getting stuck, needing constant readjustment to the tension, having Iulia need to stop quite a few times and for me to step in & attempt to troubleshoot the issue, then she would run fine & glitch out again halfway through.

By this evening both of us were quite fed up with her, but Iulia more so than I, she was at the verge of despair by the end, or rather in her own exact words she said that the machine had hurt her inner child. We most likely will have to hand-stitch the pieces we wanted to make instead of relying on our Sewing Machine. Although tonight I researched online & found a manual leather sewing machine that is available at quite an affordable price, so we are both looking forward to be able to upgrade to perhaps one of those in the near-future when we have the funds to spare.

Up to now Iulia had been collecting a lot of natural materials & turning them as is into earrings & small jewelry pieces, but due to the nature of the material it is quite fragile. She was playing with the idea of using epoxy resin, but she didn't like that option too much of incorporating what is natural into artificial plastic. Furthermore after having used Epoxy to create ourselves a little tea tray, she was even more offput by the idea after she suffered quite a severe allergic rash from the fumes of the Epoxy when poured & not yet hardened. Although that option is not yet completely off the table, she would much rather find a more natural option to immortalize her pieces.

While I knew of no alternative to Epoxy, she mentioned that she had seen people create Jewelry from natural materials using copper & silver, but did not know how they were made. Since I do silversmithing, I figured out with some research that it is actually done via Electroforming, a process in which natural materials are coated with a conductive paint, usually just graphite & then plated with copper via electrolysis.

I had ordered a small bench power supply & graphite powder, which was the only thing missing to give it a go ourselves. The thing that was quite magical is that one important ingredient is Copper Sulphate & funnily enough I had found a big bag of the stuff on the property when I bought the house last year & Iulia found another big bag in the attic when we were cleaning up in there a few weeks ago.

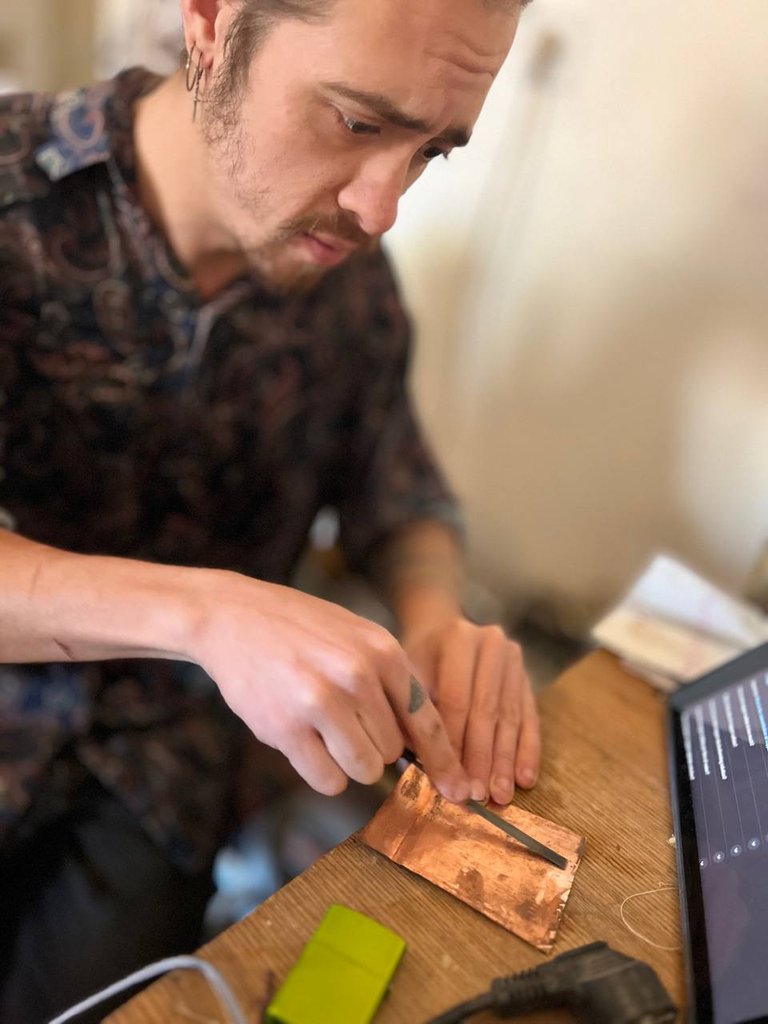

The Process is actually quite simple, so while Iulia was doing her leathercrafts today, I was busy setting up & preparing our first trial run on a small piece of bark she had.

I attached a copper wire to the piece of bark, then dipped it in my first experimental batch of conductive paint. Then I dissolved Copper Sulfate into a glass jar & added a dash of vinegar, the vinegar was a substitute for harsher acids that are usually used since it was the only thing I had available to me, usually a small amount of sulfuric acid or citric acid is used, this is recommended since the electroplating process works better with an acidic ph.

I then took some scrap copper I had so as to create the anode {+}, while the jewelry piece is acting as the cathode {-}.

The first piece was not a complete failure, I let it run for at least 1 hour but it was forming the copper very unevenly on certain parts, so at some point I stopped the process to research some more & take a proper look at the piece outside of the solution. While it looked less successful seeing it floating in the jar of sulfate solution, once taken out & cleaned from the parts that were not adhering properly, it turned out to be more successful than expected. The bark was actually getting plated with copper.

I prepared a second experimental piece made out of leather scraps which is as I am typing still being plated, but I will keep you updated on the process in one of our next posts with more detailed pics of the setup & the power supply I am using.

On another note we also setup our distillation train, for a future alchemical work. In which an Alkahest (a type of solvent) is made that will permit catalyzing an essential oil from metals & minerals.

There are several ways to obtain essential oils from Metals & Minerals, but the only way I've tried so far has been via destructive distillation, which is quite a heavy duty operation requiring very careful attention & supervision since one is working with temperatures of around 800 degrees Celsius & even borosilicate labware starts getting soft at such high temps making it quite dangerous if something goes wrong.

The Destructive Distillation pathway uses the acetate form of a metal, for example copper acetate, iron acetate, tin acetate etc. as main material, which is ground to a fine powder & put into a flask without any liquid, the flask is heated to 800 degrees Celsius upon which a lot of smoke is released, that is then cooled down via a condenser, yielding acetone, acetic acid & an oily fraction which can be separated from each other through a second distillation of the distillate, which is produced from the acetate portion of the salt, while in the distillation flask you remain with the metal in its pure form.

The oily fraction is highly interesting since it is actually composed of the same organic volatile compounds that you can find in the essential oils of many flowers & herbs.

This next method is by creating a special solvent, which later will catalyze the essential oil from a metal or mineral simply by dissolving it into it & then waiting for it to slowly react. I will go into more details about the process once we start working on it, today we just setup the distillation train making sure I have everything well prepared for when we actually start distilling.

We hope you enjoyed the journey through our day & are happy to answer any questions you might have regarding the things we are up to.

We are also rebuilding our private website at the moment & will be featuring some of our Crafts on Etsy.

Loving Regards from the 4 of us to everyone reading this post!

Congratulations @qiparosa! You have completed the following achievement on the Hive blockchain And have been rewarded with New badge(s)

Your next target is to reach 50 upvotes.

You can view your badges on your board and compare yourself to others in the Ranking

If you no longer want to receive notifications, reply to this comment with the word

STOPCheck out our last posts: