What consequences can occur with the migration of formation gas to the surface in a shut-in petroleum well?

When we have the impression that a gas surge has entered the well while we are drilling what we consider at first glance that it is safer to close the well, however once we close the well the first thing we must do is to observe the pressures that were obtained once the well was closed.

Once we have shut in an oil well the pressures that are trapped are the casing pressure and the drill pipe pressure.

Although the downhole pressures are constant, as time goes by and the well is shut in, that is no guarantee that integrity and safety is guaranteed both in the drilling rig with all its equipment, and also in the integrity of the personnel operating it, Certainly the blowout preventer (BOP) equipment will withstand certain pressure values, however the pressure generated in the well as the gas migrates makes certain equipment and the bare formation vulnerable to fracture, which would lead to a subway gas leak, which results in a subway decontrol which is very dangerous.

It is advisable to try to keep the drill pipe pressure constant and the casing pressure constant as well, these values should be kept constant according to the values obtained from the data integrity pressure tests, because if the pressure values rise above the fracture pressure that resists the formation, the formation can fracture and drilling fluid and inflow gas can escape, but if the pressure drops below the planned values of hydrostatic pressure then more formation inflow gas will enter the well.

In order to keep these pressures constant, the choke valve must be manipulated, which is the valve that will have to be opened and closed depending on the pressure values of the casing and drill pipe.

Exercises and equations that help explain drilling fluid displacement due to formation gas expansion migration.

The first thing to consider is that if the gas once it enters the well acts according to its characteristics, then it will expand from the bottom of the well to the surface, which will displace a certain volume of drilling fluid, this fluid that is displaced by the expansion of the gas, we will see it reflected in the maneuvering tank, which is the tank that in the drilling of a well is used to receive any volume of fluid displaced in the well.

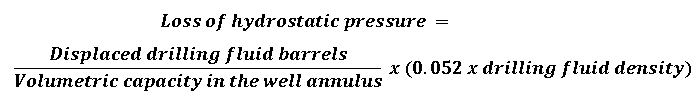

The volume of drilling fluid displaced in the well will cause a loss of hydrostatic pressure, this loss of hydrostatic pressure can be calculated based on the volume of drilling fluid that has been lost as a result of the displacement that has made the expansion of the migration gas of the formation influx, it can be calculated with the following equation:

An example of this may be:

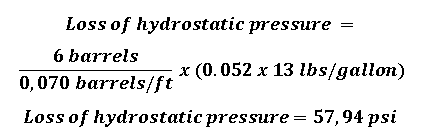

Calculate the hydrostatic pressure loss in the case where a displacement to the maneuvering tanks of a volume of 6 barrels of drilling fluid has been obtained, taking into consideration that the density of the drilling fluid is 13 lbs/gallon, and the annular volumetric capacity is 0.070 barrels/ft.

Logically this pressure drop of 57.94 psi must be compensated for, so the pressure we should seek to have at surface is 57.94 psi.

In conclusion, the migration of gas as an unwanted influx in the well brings with it a displacement of the drilling fluid, which causes a loss of hydrostatic pressure that must be compensated with the surface pressure, it is also important to know that a good management of the pressures in the well control will not allow more formation gas to enter and neither will it fracture the exposed formation.

Bibliographic references consulted and recommended

- Well Control Manual. Well Control School. Year 2003. Harvey, Louisiana.

Thanks for your contribution to the STEMsocial community. Feel free to join us on discord to get to know the rest of us!

Please consider delegating to the @stemsocial account (85% of the curation rewards are returned).

You may also include @stemsocial as a beneficiary of the rewards of this post to get a stronger support.