Reasons for injecting steam into oil formations

Hello friends of the prestigious #STEMSOCIAL community and the entire hive community.

On this occasion I want to share with all of you a post with net features of petroleum engineering to explain the reasons why steam is injected into the subsurface formations in order to extract oil.

I will also explain the method of steam injection as a mechanism for enhanced oil recovery, among the most important elements applied in the oil industry and in which you have to apply engineering knowledge is to apply within the technique of steam injection a method called cyclic steam stimulation and steam flooding into the formation.

Introduction

Although it may not seem like it, steam injection is one of the most used methods and mechanisms in the oil industry, however, perhaps for oil fields that do not have heavy oil in their reserves it is not necessary to perform steam injection, which is why we ask ourselves the following question:

Which oilfields are candidates for oil extraction by steam injection?

First of all it is important to mention that the application of this technique (steam injection) ends up being a technique that is also known as enhanced oil recovery, since there are other methods but from an engineering point of view they do not involve techniques associated with more complex and useful ways to extract petroleum more complex and useful ways to extract petroleum.

Heavy oil is the candidate to be extracted by steam injection technique, generally petroleum is heavy because its viscosity and density is very high, which is why steam injection is used, because when injecting steam we are heating the formation, and as it is well known by science and engineering when the temperature increases the viscosity decreases.

Another factor to take into account in steam injection is that when we inject steam through the injector well, we also manage to somehow clean the nearby well which is the producer, the process of reducing the viscosity of the oil occurs when the oil is separating from the asphaltenes and kerosenes causing the oil to detach from the storage rock.

Technology in the process of steam injection in oilfields

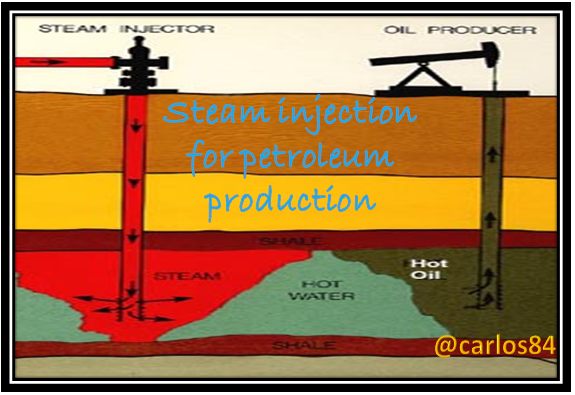

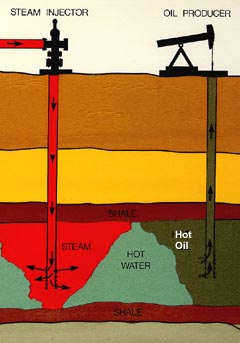

The technology and advancement of gas injection processes consists of drilling two wells, one of these wells will be an injector well where steam will be injected to heat the formation.

Once the formation is heated, the viscosity of the petroleum decreases so it can flow from the formation to the vicinity of the producing well, where most likely there is a method of artificial lift such as a pumping method such as a rocker arm.

As can be seen in the previous image, the injector well is the one in red color, this petroleum migrates to the producer well which is the one shown in the image in green color and its production method is mechanical pumping by means of a rocker arm.

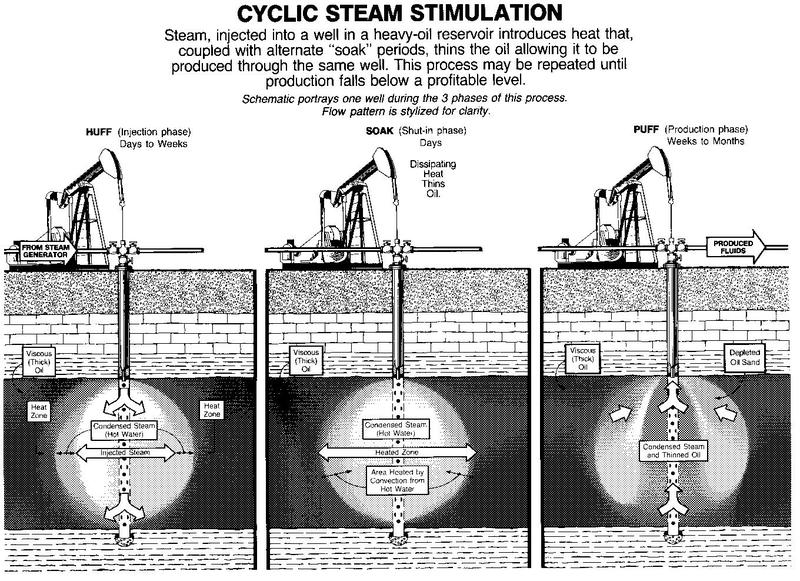

Cyclic steam stimulation

This is a method that is basically applied in several steps, one of these steps is that in the drilling of the injector well steam injection is applied for as long as necessary to heat to an estimated temperature of 300° Celsius to the formation and can migrate to the producing well.

The next step is to let the well rest once the steam injection has been performed, this resting time may vary depending on the size of the producing reservoir and other factors such as the type of lithology of the formation, among others, however for all the heat generated by the steam can penetrate to the producing formation may take weeks so that the oil can begin to migrate to the producing well.

As a last step, the hot oil is pumped out of the well by means of an artificial lift method such as a rocker arm, this production time lasts a few weeks, until it is noticed that the oil production drops and is where the cycle must be repeated again.

Steam flooding

Steam flooding occurs when multiple injection wells and a considerable number of production wells are used, in this mechanism a steam-assisted gravity drainage system is applied, in which two horizontal wells are drilled, where the upper well is the injector and the lower well is the producer, the upper well heats the formation and the oil falls by gravity and is produced from the well below.

References

Well informative post

Thanks for sharing...

Thanks for your contribution to the STEMsocial community. Feel free to join us on discord to get to know the rest of us!

Please consider supporting our funding proposal, approving our witness (@stem.witness) or delegating to the @stemsocial account (for some ROI).

Please consider using the STEMsocial app app and including @stemsocial as a beneficiary to get a stronger support.