Oil Well Drilling Problems: Sticking of Pipe

Hello friends and lovers of content related to engineering and STEM content in general.

In this opportunity I want to explain one of the problems we encounter when we are drilling an oil well, in this case the problem is when the drill pipe is stuck at the bottom of the well.

It is important to quickly identify when the drill pipe is stuck at the bottom of the well, because if you do not know how to identify the jamming of the pipe you can make the mistake of forcing the rotation or tensioning the pipe to remove it from the bottom of the well, when this is done the stress values that the pipe can withstand are exceeded and therefore it can break and remain at the bottom of the well.

Petroleum engineering studies the causes, effects and solutions of pipe sticking, all with the intention of avoiding possible complications that can lead to loss of time, economic losses and even the total loss of the well being drilled.

How do we know when the drill pipe is stuck downhole?

The first thing we must know in drilling wells to identify when the drill pipe is stuck, is to understand the movements that the pipe makes in that progress of deepening the well, these movements are rotation of the string and movements up or down vertically or inclined.

The reasons why it is important to identify these natural movements of the pipe while we are drilling an oil well, is that if we find any restriction to rotate the pipe or we find any impediment to remove the pipe or even we want to continue drilling and the rotation stops completely, it is because most likely we are in the presence of a stuck pipe.

The indicators that can serve as an alarm to the driller to know that the drill pipe is stuck are the torque values, in this case the driller notices high torque values, another variable is that when we try to pull the pipe from the bottom of the well and we see that the load on the hook increases considerably.

Let's review a little bit the indicators, if we try to rotate and we observe an increase in the torque it is probably because the pipe is stuck, if we try to go up (pull the pipe from the bottom) and we observe an increase in the hook load it is because there is a probability of encountering a pipe sticking.

But many may wonder: What happens when you try to go down and continue drilling?

When the pipe is lowered it may happen that we observe an increase in the weight of the bit or even observe an increase in the drag, these readings of these indicators are due to the probability of encountering stuck pipe.

What causes pipe sticking?

Logically, when the pipe sticks to the bottom of the well, it is because there are several restrictions that prevent it from performing the movements mentioned above, therefore these restrictions (causes) can be classified as follows:

Sticking of pipe by packing.

Pipe sticking due to differential.

Sticking of the pipe due to the geometry of the well.

Pipe bonding by gasketing

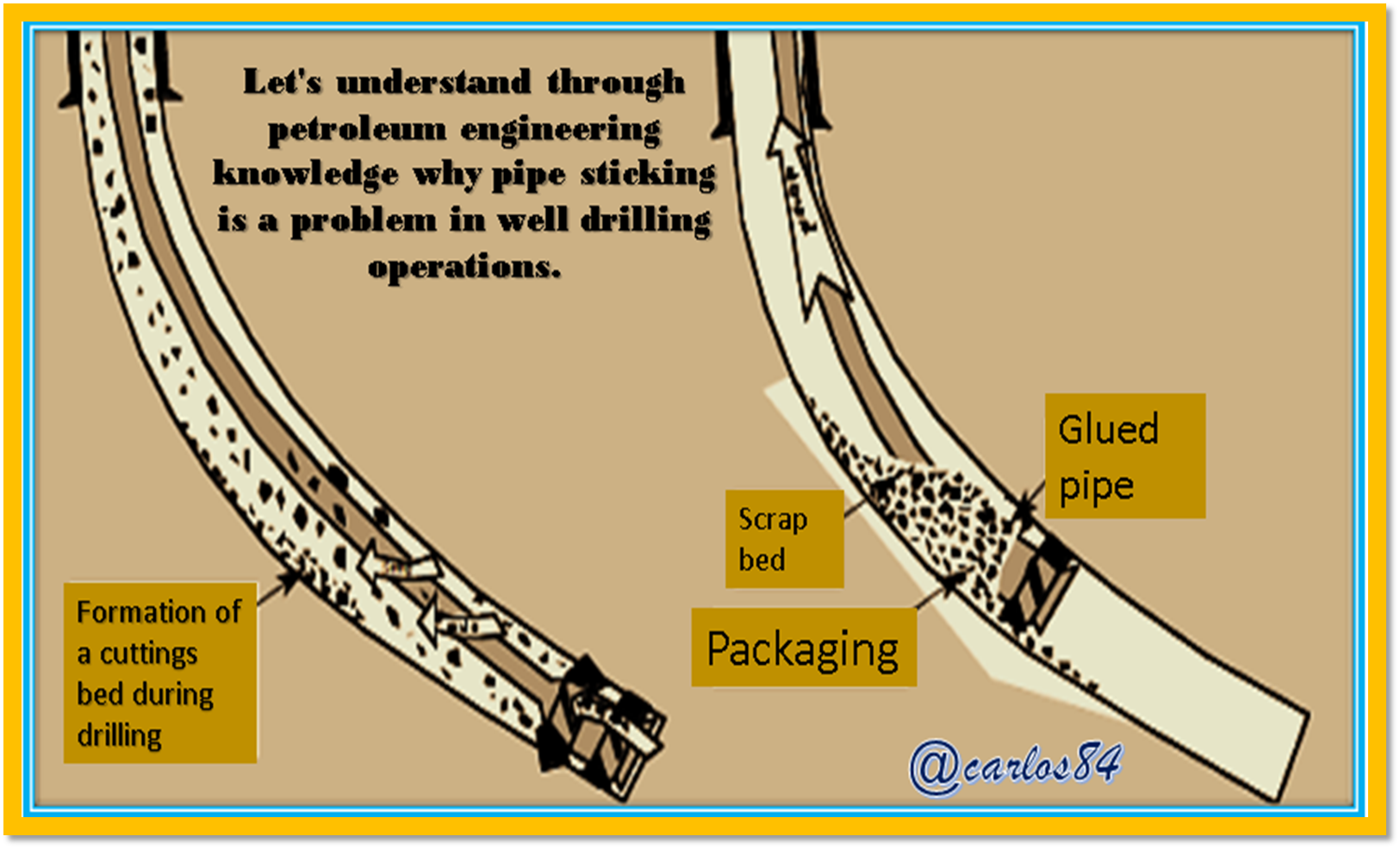

I consider it appropriate to explain this type of pipe bonding, by means of the description of the following image:

As we can see in the first well from left to right, while we are drilling, formation cuttings are generated as a result of the drill bit cutting the bottom of the well, these cuttings (cuttings) if they are not transported out of the well by the drilling fluid out of the well, they will fall to the bottom of the well until they accumulate in large proportions to completely plug the drill bit as can be seen in the second well from left to right.

When an attempt is made to pull the drill pipe string out, it will not be able to come out due to the accumulation of drill cuttings. If it is stressed and forced out, it may run the risk of exceeding the tensile stress limits of the drillpipe.

Not only are the reasons for drill cuttings accumulation not due to poor hole cleaning, there are other reasons for which packing can occur, for example if we are drilling in a zone whose lithology is poorly consolidated, there is a chance that we will drag bits of formation as we pull out or lower the drill string.

Since drill collars are the largest diameter pipe, they pull cuttings from the borehole walls that can then cause the pipe to stick by packing.

One of the reasons for drilling with an oil-base fluid in sections with shale rock lithology is that if you drill with a water-base fluid, the water phase can swell the shales, causing the swelling to cause the pipe to stick by packing.

Paste differential

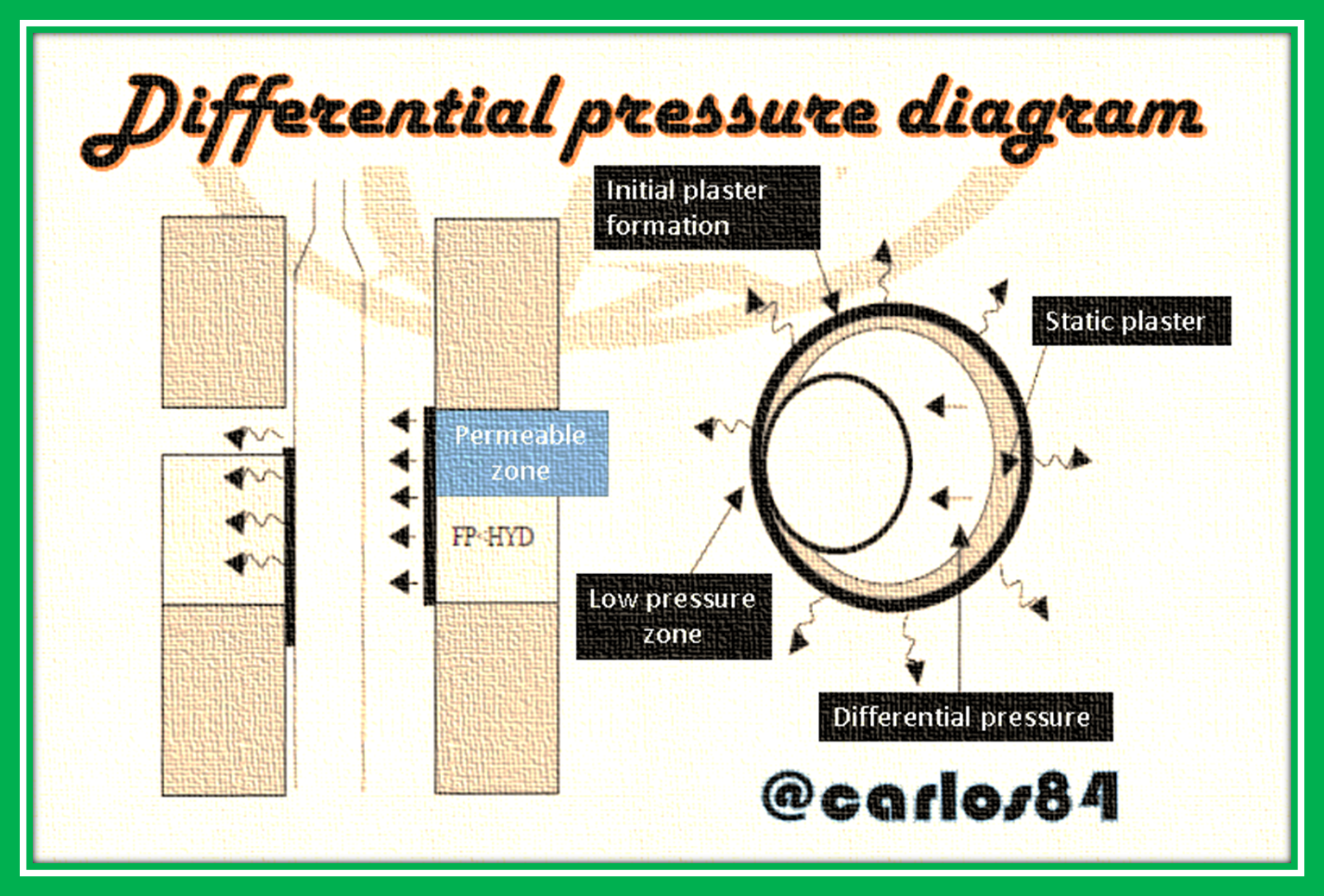

Differential sticking occurs when there is a differential pressure at the bottom of the well, where there is a scenario that favors the occurrence of such differential pressure, since if we are drilling a formation with low permeability and at the same time such formation has a lower pressure than the hydrostatic pressure exerted by the drilling fluid, then we will have a differential pressure that causes the pipe to stick to the walls of the well and therefore ends up with a sticking of the pipe by pressure differential.

Another factor that we must control the drilling fluid is the filtrate, since a high filtrate will cause the formation of a thick plaster on the walls of the hole that favors the sticking of the pipe by differential pressure.

As seen in the previous image, we can see how the pipe when passing through the permeable and low pressure zone makes the pipe lay down to the walls of the well, in the second diagram we can see that there is an initial formation of the plaster, and that together with the static plaster generates a differential pressure that makes the pipe lay down to the low pressure zone.

Well geometry

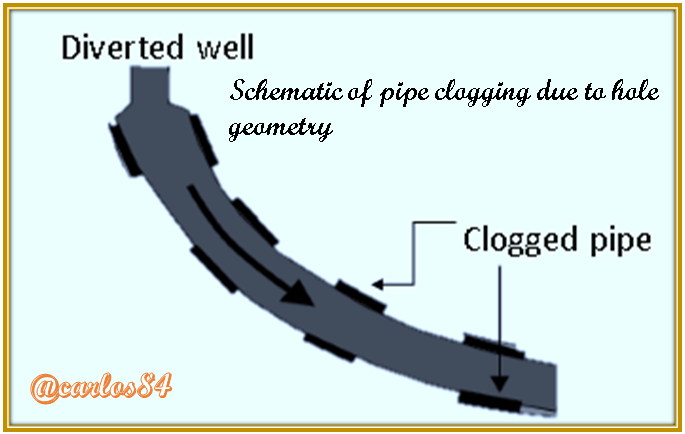

Generally when we take care to perform a proper hole cleaning, and we take care to drill through a low permeability zone, perhaps then we would be taking care of a pipe sticking, however we would only be taking care of a pipe sticking under those preventions only in wells whose geometrical configuration is vertical.

In inclined (deviated) wells it is likely that we can suffer from a pipe sticking, since the drilling of deviated (directional) wells must be done with a low drilling speed (controlled speed), because if we are drilling in a directional well we must take care that the tools that accompany the drill pipe string does not get stuck in the inclined parts of the well.

Conclusion

Within the aspects of engineering there is a more valuable philosophy than the detection of problems, before a stuck drill pipe it is not so important that we can identify the type of sticking, but rather to know the causes that originate it, and based on this to find the strategies to avoid as much as possible that the pipe gets stuck at the bottom of the well.

Based on the above mentioned it is more meritorious that we achieve that the pipe never gets stuck, then in that same meritorious order logically is that engineering must teach the different methods to solve the problems with stuck pipe.

Bibliography consulted and recommended

Downhole procedures and operations. DATALOG Drilling Manual. Version 3.0. March 2001. See page to download book in PDF format

Petroleum engineering is such an unknown World for me! It is great to read about the technical issues that I may have never thought before about.

Thanks!

Hello friend, I'm glad you found it interesting, very soon I will be explaining a new post about this thematic series.

Thanks for your contribution to the STEMsocial community. Feel free to join us on discord to get to know the rest of us!

Please consider delegating to the @stemsocial account (85% of the curation rewards are returned).

You may also include @stemsocial as a beneficiary of the rewards of this post to get a stronger support.

One of my former colleagues in the applied half of my analysis group was working on problems related to this. It is quite remarkable that some of these problems are so advanced that you need advanced modelling mathematics to solve them. :3

Hi @mathow.

Certainly when the drill pipe gets stuck in the well it is a very serious problem, as money is lost due to non-productive time and as the days go by the risk of having to leave the pipe at the bottom of the well and pump a cement plug and perform a side track increases.

It is very important the mathematical calculations, because for example when the drill pipe is being tensioned to release it from its jam it must be done under a force limit, because if this limit is exceeded the pipe can break, to know the tension limit it is necessary to perform some mathematical calculations that are involved in this operation.

Greetings and thank you very much for your valuable comment which encourages me to continue generating content like this.

Your content has been voted as a part of Encouragement program. Keep up the good work!

Use Ecency daily to boost your growth on platform!

Support Ecency

Vote for new Proposal

Delegate HP and earn more

Thank you very much for your support. Regards

All those techniques and strategies are indeed so advanced. I assume that what you wrote is valid both for drilling offshore and inside land. Is it the case?

Cheers!

Hello friend @lemouth.

Certainly the same odds you have for drill pipe to get stuck in onshore drilling are the same odds you have for pipe to get stuck in offshore drilling.

Likewise, since it is the same odds for the pipe to get stuck both onshore and offshore, then the solutions for debottlenecking are the same onshore and offshore.

Greetings friend and for me a pleasure to see a comment on my posts. Thank you very much for commenting.

I see. Thanks for your answer. I was (naively) imagining that maybe the fact of being offshore could render things more complicated.