Influence of viscosity on drilling fluids

Hello friends and STEM content lovers, this time I want to share with all of you how such an important physical property as viscosity impacts the use of fluids with which we deal in the oil industry.

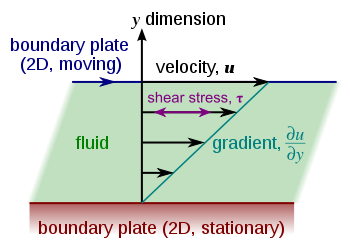

Viscosity is a physical property that is only studied in fluids, i.e. liquids and gases, this is because viscosity is a measure that measures the resistance of the same fluid to flow, for this we must understand that as a fluid moves it is constantly deformed depending on the speed it acquires in its movement, the rate of deformation is measured by the resistance that any fluid presents to such deformation.

In liquids it is very common to speak of thickness when we refer to viscosity, this term of thickness confers a less abstract understanding of viscosity, since for example when we seek to compare the fluidity of a liquid we can realize for example that a syrup has a higher viscosity than water, i.e. the syrup offers greater resistance to be deformed while moving.

Like other physical properties, in the fluids used in the oil industry, viscosity can vary its values depending on the conditions in which the fluid is subjected, i.e. for example if it is the drilling fluid, its viscosity will depend on its variability depending on its temperature, pressure and deformation rate, which I will explain below:

Temperature: when a well is drilled deeper, which confers higher temperature, the viscosity measured at the surface of the drilling fluid is not the same in the depths of the well, since at higher temperatures the viscosity is lower, which is why it is necessary to be adjusting these viscosity values as the well is deepened.

Pressure: the pressure that must be applied to break the gels in the drilling fluid confers that the pressure at which the drilling fluid is statically in the wellbore must be broken by a higher pressure which is the pump circulating pressure, The gel property is a property that in the drilling fluid is used so that when the mud pumps are paid the gels make the rock cuttings remain suspended and do not plug the hole, when the mud pump is turned on and the well is put into circulation, a higher pressure must be applied so that the drilling fluid returns to the initial values of viscosity.

Deformation rate: as the drilling fluid is a non-Newtonian fluid it has a variation in its deformation rate, however this is not a disadvantage in relation to its main function which is the transport of the rock cuttings that are cut by the drill bit at the bottom of the well as it is drilled deeper.

Conclusion

Logically, any technological advance in relation to other types of drilling fluids in the oil industry must contemplate the correct viscosity values to be able to withstand the downhole temperatures without losing the viscosity values of the fluid so necessary for it to fulfill its functions of cleaning the hole, for this chemical additives must be tested and analyzed in various fluids which in turn must be tested in laboratory simulating the conditions of pressure and temperature that are at the depths of a well drilled at high depths.

References

Thanks for your contribution to the STEMsocial community. Feel free to join us on discord to get to know the rest of us!

Please consider delegating to the @stemsocial account (85% of the curation rewards are returned).

You may also include @stemsocial as a beneficiary of the rewards of this post to get a stronger support.