Water Treatment "Part 23": Membrane filtration plants.

Because salt-laden water must flow through the membrane to reach its surface, materials must accumulate there. As a result, the pore blockage phenomena worsens and the osmotic pressure increases. To lessen the build-up of materials on the membrane's surface, there are three options available:

- 1- Periodic cleaning of the membrane is required, and this necessitates the membrane having a mechanical structure that enables liquid to pass in both directions.

- 2- Lowering the fluid's flow rate across the membrane.

- 3- By making the liquid pass parallel to the surface of the membrane, the liquid instead collides obliquely with the membrane surface rather than vertically. This affects the percentage of retained salts.

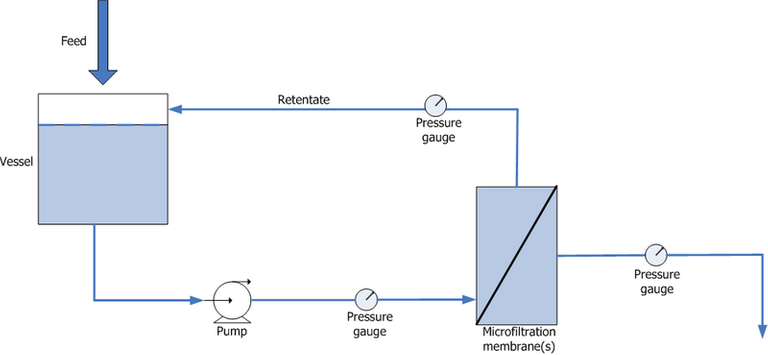

Overall setup for the Microfiltration system

The rate of recovery is equal to the proportion of the water flowing through the membrane to the raw water entering, and elements held on the membrane's surface are removed in the form of a concentrated solution. If the recovery rate is, for instance, 75%, the flow of treated water exiting the filtering system corresponds to 75% of the flow of raw water entering the treatment unit, the remaining 25% is made up of the 400% saltier brine that was trapped behind the membrane in the raw water. For microfiltration and ultrafiltration, the recovery rate varies from 85% to 99%. The recovery rate in the nanofiltration system is between 65% and 80%.

Models of treatment plants for membrane filtration employing NF, UF, or MF filters:

- Model 1:

Preliminary treatment comes before membrane filtration, and sterilisation is the sole step that follows. The raw water requirements, particularly the level of turbidity, are used to define the pre-treatment conditions. This model is typically used to clear out particular contaminants from water that conventional treatment techniques were unable to eliminate or to clear out water with mild turbidity.

- Model 2:

Membrane filtration combined with the processes of agglomeration and sedimentation, as well as pre-treatment, sterilisation, and modification as required. When the water is heavily turbid and has many suspended particles, this model is employed.

- Model 3:

This model is used when there are significant levels of organic contaminants that need to be disposed of prior to filtration and involves an oxidation step before the membrane filtration, sterilisation, and modification as necessary.

References:

- [Introduction to Water Chemistry (Pollution- Treatment- Analysis). Dr. Nasser Al-Hayek. Publication of the Higher Institute for Applied Sciences and Technology (HIAST). Syrian Arab Republic, 2017.]

- Taparhudee, Wara (2002). "Applications of Paddle Wheel Aerators and Diffused-Air System in Closed Cycle Shrimp Farm System" (PDF). Witthayasan Kasetsart (Sakha Witthayasat). 36: 408–419. Retrieved 26 April 2020.

- Unsafe water kills more people than war, Ban says on World Day". UN News. 22 March 2010. Retrieved 10 May 2018

- Raymond Desjardins- Livre: Le traitement des eaux- 2éme edition- Ecole Polytechnique de Montréal- 1997- ISBN 2-553-00643-8

- Drinking Water Treatment- EDX- Delft University of Technology.

- Book- Drinking Water: Principles and Practices- by Hans J C Van Dijk (Author), Jasper Q J C Verberk (Author), Peter J De Moel.

Thanks for your contribution to the STEMsocial community. Feel free to join us on discord to get to know the rest of us!

Please consider delegating to the @stemsocial account (85% of the curation rewards are returned).

You may also include @stemsocial as a beneficiary of the rewards of this post to get a stronger support.