Chemistry of Glass "Part 4": Glass Raw Materials.

In the glass industry, calcium-silicate glass makes over 80% of the global output. There are three primary types of oxides used to make glass:

- Vitrifier (70 Percent) Example: SiO2.

- Fluxes (15 Percent) Example: NaO2.

- Stabilizer (10 Percent) Example: CaO.

plus 5% of additives that enhance the characteristics of glass, for instance: 1% to 2% of Al2O3.

1- Vitrifier:

SiO2, B2O3, Ge2O3, and P2O5 are the oxides that make up the glass (vitreous lattice). To produce glasses with great chemical and thermal resistance, silica (SiO2) must be used. Quartz sand, which contains around 90% silica, is almost solely used to incorporate silica (SiO2) into the chemical makeup of glass. The Fe2O3 impurity in the quartz sand is the most problematic since it results in a colour after fusing; glass turns dark green if it contains between 3 and 4 percent Fe2O3.

The granulometry of the sand grains must be kept within the range of 0.2 mm to 0.8 mm; otherwise, too-large grains react with other elements insufficiently, while the presence of small grains with a diameter less than 0.2 mm might result in compositional heterogeneity.

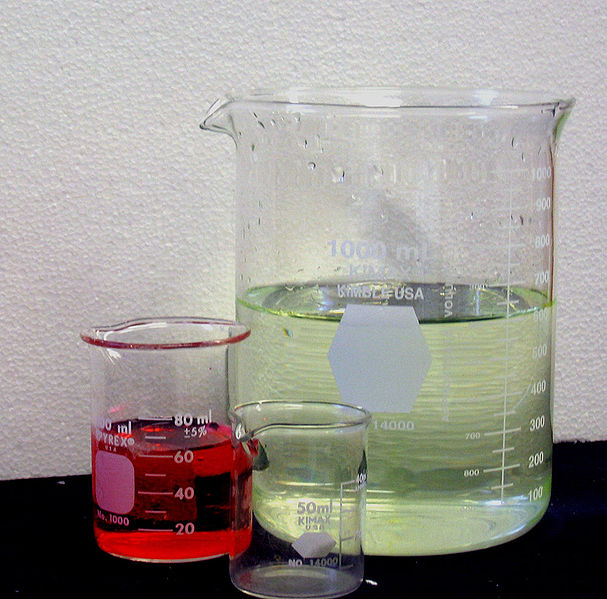

Boric acid H3BO3 and BORAX (Na2.B4O7.10H2O) are the sources of Boron trioxide B2O3, which is the second vitrifier. Boron trioxide B2O3 is rarely used alone as a vitrifier, it can be used in conjunction with silica to lower the thermal expansion coefficient, which increases thermal shock resistance and chemical resistance. A BOROSILICATE glass is produced in this instance (SiO2+ B2O3), which has a B2O3 content > 5% and an alkali oxide Na2O content < 10% (Glass used in laboratories is BOROSILICATE).

Borosilicate beakers

2- Fluxes:

Flux addition serves to reduce the glass's melting temperature. The fluxes are considered network modifiers since they weaken the vitreous network when introduced and are used with vitrifiers to change the characteristics. Sodium carbonate, or Na2CO3, which is delivered as sodium oxide and melts around 850°C, is the flux that is most frequently utilized, it decomposes in the form:

Na2CO3 ===== Na2O + CO2

3- Stabilizers:

To enhance the general qualities of glass, stabilizers are added to vitrifiers and fluxes. If the Na2O percentage is large, the glass dissolves in water, making SiO2 and Na2O-only glasses particularly attractive. Stabilizers are considered to be vitreous network modifiers.

ZnO, CaO, MgO, PbO, and Al2O3 are the major stabilizers. The mechanical qualities of calcium glass are enhanced while their expansion is decreased by the addition of magnesium oxide, MgO, in low concentrations. Dolomite (CaCO3.MgCO3) is a source of magnesium oxide.

Dolomite and Talc, Luzenac, Ariège, France

Adding lime, or CaO, to glass is a common practice because of its inexpensive cost and the fact that it offers the glass adequate average qualities. CaO is often added in the form of CaCO3 (limestone), which is easily available.

References:

- [General and inorganic chemistry book- M. Shkhashirou- H. Birqdad- Y. Qodsi- University publications. Algeria]

- Glass and Ceramic Technology Course (2021). Professor Khelifa- Department of Materials Process Engineering- University of Mostaganem. Algeria.

- Les matériaux au cœur du processus d'innovation- Clefs CEA No 59.

- Neumann, Florin. "Glass: Liquid or Solid – Science vs. an Urban Legend". Archived from the original on 9 April 2007. Retrieved 8 April 2007.

- Helène Tregouët. Structure et cristallisation de verres d’oxydes simples riches en bore et en terres rares. Chimie-Physique [physics.chem-ph]. Université Pierre et Marie Curie- Paris VI, 2016. Français. NNT: 2016PA066032. tel-01358710.

Thanks for your contribution to the STEMsocial community. Feel free to join us on discord to get to know the rest of us!

Please consider delegating to the @stemsocial account (85% of the curation rewards are returned).

You may also include @stemsocial as a beneficiary of the rewards of this post to get a stronger support.